Optimizing Photovoltaic Performance by Kinetic Quenching of Layered Heterojunctions

INTRODUCTION

Polymer solar cells (PSCs) are a kind of potential clean-energy

technology, which holds promise for manufacturing lightweight

and highly flexible devices such as portable electronic products

and building-integrated photovoltaics.[1−5]

Although the power

conversion efficiency was dramatically improved recently, it has

not yet broken through the requirements of commercial

markets due to the limitation on the mechanism of charge

carrier generation and transport.[6,7]

To date, a considerable

effort has been devoted to creating novel π-conjugated

polymers to improve photovoltaic performance. In contrast,

understanding the morphology effect on PSC performance and

formulating basic rules that guide morphology optimization

need to be further enhanced.

Optimizing the morphology is indispensable for the suc-

cessful preparation of PSCs with outstanding performa-

nce.[8−12]

The PSC performance can be quantitatively correl-

ated with phase purity and Flory-Huggins parameters.[13]

In-

sufficient phase separation in PSCs can lead to performance

deteriorations. However, a larger repulsion between donors

and acceptors can lead to over-purification of mixed domains

and decreased PSC performance.[14]

For example, Ade et al.

observed that the average power conversion efficiency shows

a substantial drop as the composition of the amorphous

mixed domains is below the percolation threshold.[15]

Ye et al.

recently found that such a problem can be resolved by kinet-

ically quenching the mixed domains to an optimal composi-

tion close to the percolation threshold.[16]

Despite this, funda-

mental guidelines are still required to optimize PSC perform-

ances with optimal mixing morphologies. Combining ther-

modynamic effects and kinetic controls can assist the design

of heterojunctions with varied mixing morphologies.[16]

The

thermodynamics can drive the phase separation of donors

and acceptors in PSCs, and the quench by kinetic control can

"lock-in" instantaneous phase-separated morphologies. Re-

cent attention has been paid to the stability of such mixing

morphologies.[17−20]

However, little is known about the kinet-

ic route to control mixing morphologies and the influence of

mixing morphologies on PSC performances. Quantifying the

impact of mixing morphology on device performance by de-

veloping kinetic control rules is the key to optimizing the het-

erojunction structure and promoting power conversion effi-

ciency.

Theoretical computation and simulation, such as kinetic

Monte Carlo simulations, can avoid trial-and-error experi-

ments and improve experimental efficiency. The drift-diffu-

sion model, requiring less computational cost than the kinet-ic Monte Carlo model, can predict the photovoltaic perform-

ances.[21,22]

Ganesan et al. predicted the photovoltaic per-

formance of rod-coil block copolymers by inputting the den-

sity profile and orientational order parameter obtained from

self-consistent field theory calculations into the drift-diffu-

sion model.[23]

The drift-diffusion formalism allows them to

account for spatially varying morphologies and the aniso-

tropy in charge transport within an internally consistent

framework. Dissipative particle dynamics (DPD), coupled with

the drift-diffusion model, is an alternative to study the PSC

performances.[24−26]

We have applied the DPD simulation to

study the phase behavior of various polymer systems and

used the drift-diffusion formalism to calculate the photovolta-

ic performance of block copolymer solar cells.[24,25]

The com-

putation showed that the DPD coupled with a drift-diffusion

model is a powerful tool for predicting performance and

peering into the internal mechanism.

In this work, we conducted an in silico layer inter-diffusion

experiment in the framework of DPD simulations. One-step

and two-step quench strategies, based on thermodynamic

driving and kinetic controlling, were proposed to regulate the

mixing morphologies. The density information obtained from

the DPD simulation was input to the drift-diffusion model to

predict the photovoltaic properties. One-step quenching res-

ults demonstrated that optimal interfacial width results in the

excellent photovoltaic performance of layered heterojunc-

tion. We discovered that the two-step quench could help to

form rough interfaces and small-length-scale islanded struc-

tures connected with the interfaces, which are conducive to

the improvement of photovoltaic performance. Our predic-

tion shows good agreement with experimental findings and

can explain the impact of PSC morphology on performances

quantitively.

COMPUTATIONAL METHODS

We developed a multiscale method combining dissipative

particle dynamics (DPD) with a drift-diffusion model to

investigate the PSC photovoltaic performance. The DPD was

first conducted to obtain the structure of polymer blends

consisting of donors (D) and acceptors (A). And then, the

structures were input into the drift-diffusion model to calculate

the photovoltaic performance. The DPD method and drift-

diffusion model are given as follows.

DPD Method

The DPD, firstly proposed by Hoogerbrugge and Koelman, is

a stochastic simulation technique for simulating the dynamic

and rheological properties of complex fluids.[27]

The details of

the DPD method can be found in Section 1 in the electronic

supplementary information (ESI). A DPD bead represents a

cluster of atoms/molecules in the method.[28−33]

The motion of

DPD beads obeys the Newton equation of motion. The force

applied to each bead comprises non-bonding forces and

bonding forces. The non-bonding force fα

applied on the α

th

bead includes a conservative force , a dissipative force ,

and a random force . The neighboring beads in each

polymer are connected by a harmonic spring potential

with the spring constant kb=100 and the

equilibrium bond length req=0.86rc

. All physical quantities are in

reduced units, where the units of time, length, mass, and energy

are τ, rc

, m, and kBT, respectively. The physical lengths in our

system were established as follows. We equated rc

to 2 nm to

build a bridge between simulation parameters and

experimental values. The thickness of layers sandwiched

between two electrodes (Lthickness) was set to 100 nm, and the

width Lwidth of each A (or D) layer is 20 nm.

We conducted the DPD simulations in a box with periodic

boundary conditions. The NVT ensembles were adopted in

the simulation, and the time step was set as Δt=0.002τ. Con-

sidering the finite size effect, we chose the A (or D) polymer

with six DPD beads, the size of which should be much smaller

than the box size. The number of A (or D) polymers is 2000 to

ensure that the number density of DPD beads is 3rc

−3. To sim-

ulate a layer inter-diffusion experiment, we arranged the D

and A layers periodically with the lamellae perpendicular to

the electrode (see the inset of Fig. 1a).[13]

The interaction

strengths between the same kind of DPD beads are

aAA=aDD=25. In the beginning, the simulation with aDA=100

was performed for 1.0×104

DPD steps to relax the polymers in

each layer and minimize the interface of mixed D/A polymers.

The layered heterojunction model was prepared for sub-

sequent kinetic quenching simulation. Then, the interaction

strength is reduced to aDA=25 to allow the inter-diffusion of

the polymers. After t1

, the simulation was stopped to mimic a

one-step in-depth quenching process, and the simulation

structures were taken as the one-step quenching structures.

The mixed morphology can exhibit various states when we

adopted different processing methods. In the two-step

quench simulation, the interaction strength aDA was in-

creased after the simulation for t1

, and then another simula-

tion was performed for t2

, as illustrated in Fig. 1(a). The varied

interaction strengths aDA correspond to various blending

temperatures.

Drift-diffusion Model

We calculated the photovoltaic performances of PSCs with

various structures by solving drift-diffusion equations.[34,35]

The

details of the drift-diffusion model are provided in Section 2 in

ESI. We solved the drift-diffusion equations numerically by finite

difference methods. The equations are first discretized in three

dimensions and then solved by the double conjugate gradient

method and Gauss-Seidel iteration method. The parameters of

the model used in the photovoltaic calculation are listed in

Table S1 (in ESI). Most of the parameters are typical for

polymeric materials used in PSCs.[23−25,36]

In solving drift-

diffusion equations, the periodic boundary conditions were

applied in the x- and y-directions parallel to electrodes. In

contrast, the non-periodic boundary conditions in the z-

direction normal to electrodes were set (for details, see Section 2

in ESI).

RESULTS AND DISCUSSION

The present work focuses on building the relationship between

the mixing morphology and photovoltaic performances of

polymer solar cells (PSCs). We considered a PSC system

consisting of two kinds of homopolymers, that is, donor (D)

polymers and acceptor (A) polymers, and used a multiscale

Fig. 1 (a) Schematic of the simulation method for one-step quenching and two-step quenching processes. In one-step quenching,

aDA=25, t=t1

, and t2=0. In a representative two-step quench, the aDA is 25 and 50 before and after t1

, respectively. The inset shows the

initial simulation model of PSC device, where the layer thickness and the layer width are 100 and 20 nm, respectively; (b) One-

dimensional density profiles of acceptors along the x-direction normal to the interface at various blending time; (c) Plots of interfacial

width and order parameter as a function of blending time t. The insets show the corresponding mixing morphologies, where blue, green,

and brown colors are assigned to the D domain, the A domain, and the interface, respectively; (d) Plots of output current as a function of

applied voltage for the layered heterojunction obtained at various blending time in a one-step quench.

method coupling DPD with drift-diffusion models to explore the

morphology effect on PSC photovoltaic performances.[24,25]

The

in silico experiment of layer inter-diffusion was first performed

using DPD simulations, and then the photovoltaic performance

of the PSC system was investigated by solving drift-diffusion

equations.

To simulate a layer inter-diffusion experiment,[13]

we ar-

ranged the D and A layers periodically with the lamellae per-

pendicular to the electrode (Fig. 1a). We stimulated both the

one-step quench and two-step quench processes to obtain

layered heterojunctions with varied mixing morphologies. In

a one-step quench simulation, the blending time is continu-

ously adjusted to gain layered heterojunction with various in-

terfacial widths. In a two-step quench simulation, we can

achieve the layered heterojunction with sufficient phase-sep-

arated mixed domains. The details can be found in the Com-

putational Methods section.

One-step Quench

This subsection adopted a one-step quench method to achieve

heterojunction structures with various interfacial widths and

explored the relation between photovoltaic performances and

interfacial width. In the initial period of quenching simulation,

the interaction strength aDA between D and A polymers was set

as 25, which equals the interaction strengths between the

beads of the same type, to simulate the inter-diffusion of D and

A polymers at high temperature. As time goes on, the D/A

interface gradually widens through inter-diffusion, and the

layered heterojunction slowly evolves toward a thoroughly

mixing state (mixing heterojunction). To generate layered

heterojunctions with various interfacial widths, we stopped

the simulation at different time to mimic the quenching process

where the temperature drops rapidly to freeze the movement of

polymer chains. For example, melts of polymer blends are

frozen into a glass below the glass transition temperature. The

time when we stopped the simulation is referred to as blending

time.

Fig. 1(b) shows the density profiles of A polymers obtained

at various blending time. As shown, the fraction of A poly-

mers in the acceptor-rich domain decreases as the blending

time increases. As a result, the degree of mixing increases,

and the D/A interface broadens. To qualify such a variation,

we calculated the order parameter and interfacial width at

various blending time (the definitions of order parameter and

interfacial width are given in section 4 in ESI). The result isshown in Fig. 1(c), where the orange and blue lines corres-

pond to the order parameter and the interfacial width, re-

spectively. As the blending time increases, the interfacial

width shows a nearly linear increase and then keeps un-

changed. Different from the interfacial width, the order para-

meter gradually decreases. This result implies that the vari-

ation of order parameters can be inversely related to the

change of interfacial width. A plot of order parameters as a

function of interfacial width proves such a relationship (Fig.

S1 in ESI). Therefore, we only examined the effect of the inter-

facial width on photovoltaic performances in the following.

We also found the D and A polymers are almost uniformly

mixed (mixing heterojunction) at a long blending time (e.g.,

370τ).

The J-V curves were calculated for the layered heterojunc-

tions obtained at various blending time, under applied

voltages from −0.45 V to 1.3 V, using the drift-diffusion mo-

del. As the blending time increases, the short-current density

(JSC) increases, and the open-circuit voltages (VOC) decrease

(Fig. 1d). The output power first increases and then decreases

as the applied voltage increases (Fig. S2 in ESI). The layered

heterojunction generated at the blending time of 60τ pos-

sesses the most superior maximum output power among the

photovoltaic devices obtained at three blending times. The

photovoltaic performances, including JSC, VOC, fill factor (FF),

and power conversion efficiency (η), can be calculated from

the J-V curves to characterize photovoltaic devices. Since the

variation of mixing degrees can be related to the change of

interfacial widths (Fig. S1 in ESI), we focused on the depend-

ence of performances on the interfacial width. Fig. 2 shows

the variation of JSC, VOC, FF and η as a function of the interfa-

cial width. As shown, the photovoltaic performances exhibit

different responses to the change in interfacial width. The JSC

increases markedly with increasing the interfacial width, fol-

lowed by a slight variation of the JSC (Fig. 2a). Compared with

JSC, the values of VOC are less sensitive to the variation of inter-

facial width (Fig. 2b). And the FF shows a decrease with in-

creasing interfacial width, which resulted from the enhanced

recombination of charge carriers (Fig. 2c). The η first in-

creases and then decreases as the interfacial width increases

(Fig. 2d). The optimal interfacial width is ca. 7 nm for the D/A

heterojunction photovoltaic device. At optimal conditions,

the corresponding order parameter is 0.54 (Fig. S1 in ESI). As

the interfacial width is smaller than 7 nm, the charge carrier

generation dominates the charge carrier recombination. In

contrast, the charge carrier recombination governs the

photovoltaic efficiency as the interfacial width becomes large.

To capture the underlying mechanism enhancing the

photovoltaic performance of the layered heterojunction with

intermediate interfacial width, we calculated two-dimension-

al distributions of acceptor volume fraction, exciton density,

charge carrier generation rate, and charge carrier recombina-

tion rate. The two-dimensional distribution was obtained by

projecting the three-dimensional distribution of acceptor

volume fraction, exciton density X (m−3), charge carrier gener-

ation rate Geh (m−3·s−1), and charge carrier recombination rate

Fig. 2 Plots of (a) JSC, (b) VOC, (c) FF, and (d) η as a function of the interfacial width of heterojunction PSCs in a one-step quench. The

width of each layer is 20 nm, and the interaction strength aDA between D and A polymers is 25.

Fig. 3 Two-dimensional distributions of (a) acceptor volume fraction, (b) exciton density (m−3), (c) charge carrier generation rate (m−3·s−1),

and (d) charge carrier recombination rate (m−3·s−1) along x- and z-coordinates. The layered heterojunction has an interfacial width of 7 nm.

Reh (m−3·s−1) on the x-z plane because their distributions on

the y-axis are reproducible. The results presented in Fig. 3 are

for the polymer blends with an interfacial width of 7 nm. As

shown in Fig. 3(a), the interface between D and A polymers is

rough, which results in a substantial increase in the specific

interface area of the heterojunction compared to planar het-

erojunction. The concentration of excitons near the interface

drops significantly compared with those in the relative pure

domain (Fig. 3b), which indicates the separation of a large

number of excitons at the D/A heterojunction interface.

Based on Figs. 3(c) and 3(d), we can intuitively observe the

distribution of generation rate Geh of charge carriers and re-

combination rate Reh of charge carriers, where larger values

near the interface and smaller values in the pure domain ap-

pear. One can see that the generation rate Geh of charge carri-

ers at the interface is higher than that inside the interface (Fig.

3c). The interface offers a central site for separating excitons

and recombining charge carriers. Compared with the inter-

face, the relative pure domain is a better channel for carrier

transport in the photogeneration process for less doping of

electrons or holes. The tradeoff between charge carrier gener-

ation and charge carrier recombination determines the op-

timal interfacial width. In addition, the interfacial roughness

enables a portion of separated carriers to transport through

pure domain channels, further increasing the performance.

The photovoltaic performances are dependent on the in-

teraction strength aDA and layer width Lwidth. As the layer

width increases, the JSC decreases, but the VOC and FF in-

crease (Figs. S3a−S3c in ESI). In addition, the optimal η de-

creases with the increases of layer width (Fig. S3d in ESI). The

increase of layer width reduces the specific interfacial area for

exciton separation, leading to the reduced η. As the layer

width increases, it requires more blending time to obtain the

optimized specific interfacial area through inter-diffusion. As

a consequence, the optimal η shifts to a long blending time

as the layer width increases. The photovoltaic performance at

the longer blending time shows no evident difference be-

cause the A and D polymers are homogeneously mixed

(aDA=25).

The interaction strength aDA can be associated with the

blending temperatures in the one-step quench experiment.

Higher interaction strength means a lower blending temper-

ature. The JSC decreases, and the VOC and FF increase as the

aDA increases (Figs. S4a−S4c in ESI). At the high aDA value, e.g.,

aDA=32.5, the photovoltaic performances are nearly un-

changed, which results from deteriorative compatibility

between the D and A polymers. The temporal variation of η

depends much on the aDA value (Fig. S4d in ESI). As the aDA is

not very high, the η changes non-monotonically with time, in-

creasing first and then decreasing until it keeps unchanged.

The optimal η increases and shifts towards long blending

time with improving the aDA. As the aDA is high, e.g., at

aDA=30, the η varies monotonically with blending time—the

η increases first and then stays nearly unchanged. Note that

the mixing heterojunction and layered heterojunction are ob-

tained at high and low blending temperatures, respectively,

as the blend reaches equilibrium. At a low temperature, the η

for the equilibrium structures obtained at long blending time

decreases with increasing aDA values, which could be ascribed

to the interface narrowing in layered heterojunctions at a

higher interaction strength.

Two-step Quench

In this subsection, we further optimized the layered hetero-

junction PSCs by secondary phase separation of mixingdomains. A two-step quenching process was proposed to

modulate the phase separation and, therefore, the photovoltaic

performance (Fig. 1b). In the two-step quenching process, the

blending time t includes a high-temperature mixing time t1

and

a low-temperature separating time t2

. At a time shorter than t1

,

the aDA is 25, allowing D and A polymers to mix via inter-

diffusion at a high temperature. This process is the same as in

the one-step quenching process. At a time longer than t1

, the

aDA increases to 50 to drive microphase separation between D

and A polymers. This case mimics the phase separation of

polymer blends at a low temperature (still in the molten state).

At the time of t1+t2

, we stopped the simulation to mimic an in-

depth quenching process, where the temperature is decreased

to, for example, below glass transition temperature to freeze

polymer chains. Taking the one-step quenching process as the

benchmark, we explored the effect of secondary phase

separation on photovoltaic performances.

In the two-step quenching, the blending time t varies to

obtain morphologies with various separation/mixing degrees.

We then calculated the photovoltaic performance of these

layered heterojunctions under different blending time t. The

result is presented in Fig. 4(a). The photovoltaic performance

curve from 0 to t1

is represented by a solid blue line, which

shows no difference from the performance curve of the one-

step quench. The dashed black curve represents the photo-

voltaic performance curve from t1

to t1+t2

. For each t1

(blue

dot), we selected the optimal photovoltaic efficiency η

at

the second-step quench and represented it with an orange

dot. We connected the orange dots into a curve to represent

optimal photovoltaic efficiency curves after two-step quen-

ching treatment under various conditions. As the t increases,

the optimal photovoltaic efficiency increases initially and

then decreases slowly, whose trend is similar to that of a one-

step quenching process. With increasing t1

, the time t2

re-

quired to achieve the optimal photovoltaic efficiency η

in-

creases, especially in the late stage (t1>70τ). The result im-

Fig. 4 (a) Plots of η as a function of time t for the two-step quenching process, in which high-temperature mixing time t1

and low-temperature

phase separating time t2

are adjusted continuously. The solid blue curve and dashed black lines refer to the first-step and second-step quenching

processes, respectively. (b) Front view of the layered heterojunction obtained at t2=0, 18, 30, and 50, respectively, where the high-temperature

mixing time t1=120τ. The red and yellow arrows indicate the island connected to the interface and isolated island, respectively. (c) Plots of volume

V and interfacial area S of the heterojunction as a function of the low-temperature phase separating time t2

. (d) Plots of specific interfacial area A

deduced from S(t2

)/V(t2

) and photovoltaic performances as a function of low-temperature phase separating time t2

. The high-temperature mixing

time t1

is 120τ.

plies that the two-step quenching treatment contributes

much to the performance enhancement. Compared with the

best photovoltaic performance of 12.78% in the one-quench

process, the two-step quenching treatment can improve the

device to higher photovoltaic performance, ca. 13.05% at

t1=120τ and t2=18τ.

We found that the interaction strength has a less marked

effect on the optimal photovoltaic efficiency as the interac-

tion strength is higher, for example, at aDA=40, 50, and 60

(Fig. S5 in ESI). The low-temperature phase-separating time t2

required to achieve optimal photovoltaic efficiency de-

creases for each case as the interaction strength increases.

However, as the interaction strength is lower, e.g., at aDA=30,

the optimal photovoltaic efficiency shows an evident differ-

ence from those of higher interaction strengths. A much

longer phase-separating time t2

is required to achieve optim-

al photovoltaic efficiency.

The improved photovoltaic performance can be related to

the secondary phase separation between donor and accept-

or polymers in the mixing domains. Fig. S6 (in ESI) shows the

order parameter as a function of separating time t2

. As shown,

the order parameter increases with time, and the donor and

acceptor polymers become more phase-separated. The op-

timized performance was obtained at an intermediate order

parameter of 0.64, implying that either insufficient phase sep-

aration or the over-purification of the acceptor- or donor-rich

domains can lead to performance deteriorations. Since the

phase separation can occur both at the interface and within

A- and D-rich domains, the mechanism behind the perform-

ance optimization needs to be explored further.

To obtain a deep insight into the internal mechanism un-

derlying the enhanced photovoltaic performances at t2=18τ,

we captured the morphologies of the D/A heterojunction at

various low-temperature separating time t2

. The results are

shown in Fig. 4(b). As shown, as t2

increases from 0τ to 18τ,

the interfacial region gradually narrows, indicating the phase

separation. Moreover, the phase separations within D and A-

rich domains also happen, leading to a series of small-length-

scale islanded structures. At that time, the D/A interface is

highly structured and rough, and the phase-separated small-

length-scale islands are connected with the interface to form

continuous structures. Such an arrangement results in in-

creased interfaces for exciton separation and efficient pas-

sages for charge transport. Therefore, the η reaches the

highest value. As t2

further increases, the phase separation

goes on, and the interface becomes less structured and nar-

row, leading to a decreased exciton separation efficiency. At

t2=50τ, a flat, thin interface appears between D- and A-rich

domains. Moreover, the small-length-scale islands are inde-

pendent of the interface and become "isolated islands" with-

in D- or A-rich domains, resulting in the loss of effective trans-

port channels. The less structured interface, narrow interfa-

cial width, and isolated small-length-scale islands are harmful

to the exciton separation, leading to decreased power con-

version efficiency. The two-step quench provides a buffer for

making the interface rough and generating small-length-

scale islands connected to the interface at a lower temperat-

ure before the kinetic quenching, leading to improved per-

formance.

To further quantify the impact of interfacial roughness on

device performance, we analyzed the morphology features

of the D/A heterojunction by Minkowski functionals V and S

at t1=120τ. As shown in Fig. 4(c), with t2

increasing from 0τ to

50τ, the volume V and interfacial area S of the heterojunction

present the same tendency to go down faster at first and then

decrease slower. In this process, the acceptor and donor poly-

mers tend to come together, and the purity of the acceptor-

or donor-rich domain increases. We obtained the curves of

specific interfacial area AI

with time t2

from S(t2

)/V(t2

), which

is shown in Fig. 4(d). The curves of the specific interfacial area

of the heterojunction and the photovoltaic performance

show similar trends, both of which increase initially and reach

a peak in the dash region (t2

is around 18τ), and then drop off.

The result implies that an increase in specific interfacial areas

is a critical factor for improving photovoltaic performance.

The low-temperature phase separation in the two-step

quench plays a role in modulating the specific interfacial area.

Comparison with Existing Experimental Observations

There is some experimental evidence available to support the

simulation results. Ye et al. recently carried out a bilayer inter-

diffusion experiment to gain insight into the relationship

between interaction parameters and photovoltaic performan-

ces of organic solar cells.[13]

They established a quantitative

"constant-kink-saturation" relation between Flory-Huggins

parameter χDA and the fill factor FF in organic solar cells. To

make a comparison, we calculated the FF for the equilibrium

D/A blends obtained at various interaction strengths aDA

through one-step quench simulations for a long bending time.

χDA = (0.286 ± 0.02)Δa

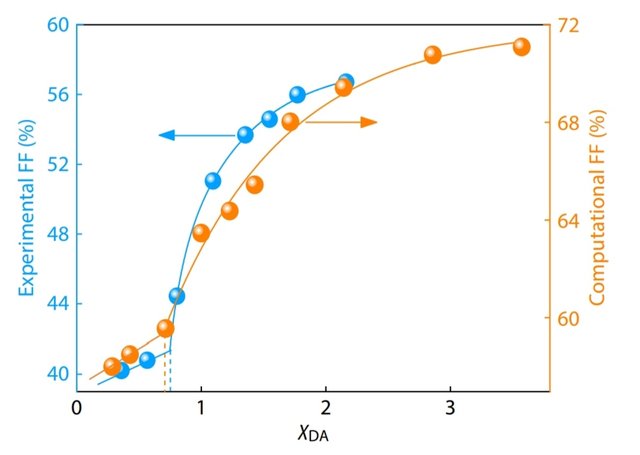

Fig. 5 shows the plot of fill factors as a function of Flory-

Huggins parameter χDA between donor and acceptor. The χDA

is related to aDA in terms of .

[37]

In the

figure, the blue and orange dots correspond to the experi-

mental and simulation results, respectively. Similar to the ex-

perimental findings, the simulation also revealed a "constant-

kink-saturation" relation between FF and χDA; that is, as the

χDA increases, the FF is first almost unchanged, then increases

sharply, and finally keeps nearly unchanged (Fig. 5). However,

the FF in the simulation is higher than that in experiments.

Fig. 5 Plots of fill factor FF as a function of Flory-Huggins parameter

χDA for layered heterojunctions obtained in a one-step quench. The

experimental results (blue dots) were adapted from Ref. [13] with the

permission of Nature Publishing Group.

This difference could result from the discrepancy between the

experimental sample and the simulation model. Different

from the all-polymer system in simulation, the experimental

model adopts the PCDTBT:PC71BM system. The molecule ac-

ceptor phases diffuse into donor phases faster, and the donor

region has a lower purity, which results in the rise of carrier re-

combination. The donor composition in the acceptor-rich do-

mains is unequal to the accepter composition in the donor-

rich domains in the experiment. However, in our simulation,

the accepter-rich and donor-rich domains are symmetric, and

both of them can contribute to the FF, resulting in an in-

creased FF. Despite that, the "constant-kink-saturation" fea-

tures are consistent. We found that a sharp increase in FF hap-

pens as χDA is higher than ca. 0.75. This threshold value, asso-

ciated with the phase separation between donors and ac-

ceptors, is similar to that (ca. 0.72) revealed in the experiment.

The consistency with experimental results implies that the

current simulation is a practical approach to reproducing the

experimental observations.

Recently, Ade et al. observed a substantial drop in power

conversion efficiency as the mixed domain is over-purified.[15]

Reducing the interaction strength between acceptors and

donors can avoid the over-purification of the domains.

However, higher interaction strength is still needed for phase

separation and, thus, optimal performance. Therefore, there is

a need to kinetically quench the mixed domains to a compos-

ition close to the percolation threshold for achieving optimal

performance if the molecular interaction of constituent ma-

terials is too repulsive. Ye et al. recently determined the

quench depth of an organic solar cell to achieve optimal per-

formance and stabilize the mixing morphology.[16,38]

The es-

sence of their work is to create percolation structures with

continuous channels by a kinetic quench. In our simulation,

we found that the connectivity of islanded structures in D/A

domains with the interface is crucial to the performance en-

hancement (Fig. 4b). The formation of islands can increase the

interface, whereas the connectivity with the interface can of-

fer transport channels. Such an observation is consistent with

the opinion that sufficient electron pathways for transport are

a critical morphological requisite for achieving desirable PSC

performances, although the length scale we focused on is

much smaller than that of mixed domains in the experiments.

Similar to polymer blends, block copolymers can also yield

various ordered morphologies. Provided that the interfacial

width and domain size of the lamellae formed by block co-

polymers are similar to those of mixing morphology, the

photovoltaic properties could be the same. We can expect

the variation of photovoltaic properties by changing the in-

terface width and domain size via varying the chemistry of

blocks and the length of block copolymers. Changing the

chemical species and polymer lengths requires synthesizing

new polymers, which usually poses challenges. In contrast,

the mixing morphology can be readily obtained by kinetic-

ally quenching the polymer blends, although the quench sys-

tem is generally more unstable than the block copolymer sys-

tem. Overall, the block copolymers can achieve similar photo-

voltaic performance with polymer blends, but their morpho-

logies are regulated through different routes.

In this work, we discovered that appropriately modulating

interfacial width, interfacial roughness, and islands' con-

nectivity with interfaces can enhance photovoltaic perform-

ance. We proposed two quenching methods to adjust these

structures of the layered heterojunctions. The work revealed

that a specific buffer time for blending and secondary phase

separation could increase the interfacial area and form elec-

tron transport pathways, leading to enhanced photovoltaic

performance. Recent observations demonstrated that

quenching to the percolation threshold is critical to perform-

ance improvement.[16,38]

Our work adds a new opinion to the

current findings: providing a buffer at a lower temperature

before the kinetic quenching can further increase photovolta-

ic performance.

CONCLUSIONS

The DPD method, coupled with the drift-diffusion model, was

employed to study the mixing morphology effect on the

photovoltaic performance of layered heterojunction PSCs. We

performed an in silico layer inter-diffusion experiment and

designed two quench approaches to regulating the mixing

morphology of layered heterojunctions, that is, one-step

quench and two-step quench. In the one-step quench, the

layered heterojunction with intermediate interfacial width

exhibits an optimal photovoltaic performance. We further

enhanced the power conversion efficiency of the layered

heterojunction by modulating the mixing morphology with a

two-step quench method. We discovered that the interfacial

width, interfacial roughness, and small-length-scale island

structures formed within acceptor- and donor-rich domains

combinedly affect the power conversion efficiency. Our work

delineates the effect of quenching processes on photovoltaic

performance, which could be beneficial to the design and

quantitative optimization of active layers.

NOTES

The authors declare no competing financial interest.

This is a one-time notice from SCHOOL OF MINNOWS, a free value added service on steem.

Getting started on steem can be super hard on these social platforms 😪 but luckily there is some communities that help support the little guy 😊, you might like school of minnows, we join forces with lots of other small accounts to help each other grow!

Finally a good curation trail that helps its users achieve rapid growth, its fun on a bun! check it out. https://plu.sh/somland/