Automating Agriculture using Machine Vision System

A camera[Source:Pxhere] - Public domain

Some situations arise where you’ve successfully consumed your food stuffs and this warrants you visit a nearby store. The supermarket doors swings open with a welcome smile, ‘glad to see you again’. Navigating through the store and selecting your needed items (milk, cornflakes) you seem not to remember the price or some detail anymore. Nonchalantly, a turn towards your right happens to be a good one and you find a barcode reader.

Blip! Blip! The black and white zebra strip on the item gives you the necessary information you need without asking anyone - how wonderful! For those who run the busy store, that technology also assist them to keep a centralized record, change price without putting tags on items and manage stock level. This example gives an insight as to how machine vision technology is being used on a daily basis around and even by us.

What is machine vision?

Machine vision system is a technology that combines mechanics, optical instrumentation, electromagnetic sensing, digital video and image processing technology. It refers to an automated system comprising of charge coupled device (CCD), cameras, and computers to electronically perceive, understanding, duplicate and perform the routine task involving a human eye and brain.

As an integrated mechanical-optical-electronic-software system, machine vision has been widely used for examining, monitoring, and controlling a very broad range of applications. It relies on extracting visual appearance in terms of shape, size and colour features acquired from digital images which are then used for automatic classification into pre-determined categories.

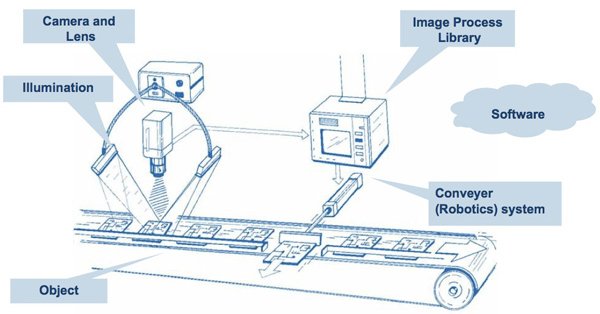

A typical setup of a machine vision system includes: lighting (Halogen light, LED light source, high frequency fluorescent source, flash source, other special light source), optical lens (CCT camera, microscope head), cameras, image processors, image video capture card, image processing software, monitors, communication/input and output units and so on.

Typically, an industrial inspection system computes information from raw images using sequence or techniques of image acquisition, image processing and image interpretation, leading to quantification and classification of images and objects of interest within images.

A typical machine vision system[Source:Wikimedia Commons] - Share-Alike 4.0

- Image acquisition

A critical aspect of machine vision systems is the production of a reputable image with good contrast and these depend on the design of a lighting system that is not affected by ambient light. Proper selection of lighting sources (incandescent, fluorescent, halogen, LED), lighting arrangements (back lighting, front lighting, side lighting, structured lighting) and lighting geometry (point lighting, diffuse lighting, collimated lighting) are important in image acquisition.

The aim of image acquisition is to generate not a digitalized and coloured image that is usable by the technology. Image capturing enables users to upload pictures from digital cameras or scanners which are either connected directly to the computer or to the network. A system consisting of a high-pixel resolution CCD (charge coupled device) chip and associated hardware is the most common method for generating digital images.

- Image processing and analysis

The image processing and image analysis are the core of computer vision with numerous algorithms and methods available to achieve the required classification and measurements. Research have it that as the classification involves more product properties and became more complex, the error of human classification increased.

Image processing filters the captured image to remove background noise, correct geometric distortions and unwanted reflection. This helps to enhance and improve the acquired image for further analysis, various processing algorithms. After enhancing the image the machine vision system applies segmentation algorithms and statistical tools such as fourier series approximation, mahalanobis distances, linear discriminants analysis, contour curvature analysis, neural networks or fuzzy systems to extract and compare features to specification.

- Image interpretation

Interpretation in machine vision system vary depending on the application domain and are related to the tasks to be accomplished, environment, speed etc. For example, in machine vision inspection applications, the system must be able to differentiate between acceptable and unacceptable variations or defects in products, while in other applications, the system must enable users to solve guidance and alignment tasks or, measurement and assembly verification tasks based on specifications and model.

Initially, machine vision technology found its application in the entertainment industry but the combination of low-cost computing power and applications has led to a readily available platform for analyzing vision signals in a variety of ways for other applications.

Applications of machine visioning techniques have expanded to various areas such as Industrial automation (Process control, quality control, geometrical measurement), Medical image analysis (Tumor detection, measurement of size and shape of internal organs, blood cell count X-ray inspection), Robotics (Obstacle avoidance by recognition and interpretation of objects in a scene Collision avoidance, machining monitoring), Document analysis (Handwritten character recognition, layout recognition, graphics recognition)

Many applications using machine vision technology have been developed in agricultural sectors, such as land-based and aerial-based remote sensing for natural resources assessments, precision farming, postharvest product quality and safety detection, classification and sorting, and process automation. This is possible because machine vision systems not only recognize size, shape, color, and texture of objects, but also provide numerical attributes of the objects or scene being imaged.

- Product quality and safety detection of agricultural products

Quality of harvested crops and pre-processed food is a critical aspect and a major decider of market acceptability, storage stability, processing quality, and overall consumer acceptance. Traditional inspection, grading and sorting involves humans, which is time consuming, less accurate, inconsistent, subjective to errors due to different judgments by different persons.

Machine vision provides an accurate, flexible, fast, objective and non-destructive method for inspection of quality and grading of crops after harvest. It has also been used successfully in the analysis of grain characteristics. food manufacturing industry is one among the top ten industries which uses machine vision technology

Computer vision has been used for such tasks as shape classification, defects detection (bruises, russet, scab, fungi or wounds), quality grading and variety classification of fruits and vegetables such as Apples, Pawpaw, Orange, tomatoes, strawberry.

Aside physical examination, this technology can also predict the inner quality and composition of agricultural produce. For example, combination of image analysis and near-infrared spectro-photometric sensors for sugar content prediction in apples; correlation of size, colour, shape and abnormalities attributes obtained from tomato images with the inner quality of the tomato samples.

Various algorithms of up to has been developed for strawberry classification based on size and shape. Computer vision has also been used in the assessment of tomato seedling quality as a classification technique to ensure only good quality seedlings were transplanted

- Vision guidance for detection of weeds

Weeds are one of the significant threats to agricultural crops and they compete for virtually every good thing that crops need. One of the control measures for weed infestation is the application of herbicide application is. Site Specific weed management and selective sprays coupled with machine vision promotes efficiency and precision in controlling weeds.

To incorporate machine vision into weed detection system, two image processing technologies namely; the green plant detection technologies and the crop and weed discrimination are employed. The green plant detection incorporates fourier transform and gray level co-occurrence matrix for image processing integrated into a mechanical structure of spraying system for weed removal.

This method takes into account colour indices such as the RGB (representing colour intensity for red light, green light and blue light), HIS (Hue Saturation Intensity), HSV (Hue Saturation Value) Or Lab (Lumination, red to green values, blue to yellow values), visible light and near infrared information for green plant detection purposes.

The crop and weed discrimination method shows more computation efficiency than the green plant detection. It uses one or more of spectrum analysis, morphological comparism, texture and frequency analysis and spatial location separation for distinguishing crops from weed in the furrow. This method highlights crop planted at constant rows and their respective center lines to guide automated machineries that separate weeds from crops. The Hough Transform is a popular algorithm used for discrimination and the speed and efficiency has been improved upon to gradient based random hough transform.

- Livestock identification and monitoring

The use of different computer vision based systems for animal tracking and monitoring in livestock is rapidly developing an area within precision livestock farming research field. There are solutions suited for segmenting animals from the background in different areas of a dairy barn and distinguishing between different behavioural states.

Systems used in identifying livestock behaviours can be classified based on their ability to record biomechanical information for modelling behaviour (such as a motion capture system) and on the basis of recognising and quantifying behaviours automatically from video (behaviour recognition systems).

Practical applications include the use of machine vision to determine appropriate parameters to regulate the thermal conditions within their enclosure, detection and tracking of broiler chickens and also identification of birds interaction with the drinker and feeder system to indicate if birds are in healthy state.

This write-up has discussed some of the applications of machine vision to agriculture. The use of machine vision technology in manufacturing can be as simple as producing an inspection quality report or as complex as total process automation. An ambiguity of computer vision is that its results are influenced by the quality of the captured images. Therefore, if a good quality image is not obtained as a standard, it will negatively affect the entire vision system. Also due to the unstructured nature of typical agricultural settings and biological variation of plants within them, object identification in its applications to agriculture is considerably more difficult. More to, most application of machine vision to agriculture hasn't been perfected and scaled-up to reasonable commercial level - but with time and research focus this will be a thing of the past.

Thank you for your time

References

- David Dechow. The Fundamentals of Machine Vision.

- Jitendra Paliwal et al 2015. Towards Machine Vision Based Grain Classification: Challenges and Future Prospects

- John Billingsley 2014. Machine vision applications in agriculture

- John Billingsley 2014. Machine vision in Agriculture

- Krishna Kumar Patel et al 2011. Machine vision system: a tool for quality inspection of food and agricultural products

- Matthew Tscharke and Thomas M. Banhazi 2016. A brief review of the application of machine vision in livestock behaviour analysis.

- Neeraj Singh Visen 2002. Machine vision based grain handling system

- Oleksiy Guzhva, 2018. Computer vision algorithms as a modern tool for behavioural analysis in dairy cattle.

- Yang Yang et al 2010. Application Analysis of Machine Vision Technology in the Agricultural Inspection

- Yud-Ren Chen et al 2002. Machine vision technology for agricultural applications

This post has been voted on by the SteemSTEM curation team and voting trail in collaboration with @utopian-io and @curie.

If you appreciate the work we are doing then consider voting all three projects for witness by selecting stem.witness, utopian-io and curie!

For additional information please join us on the SteemSTEM discord and to get to know the rest of the community!

I have always known machine vision for its speeds, accuracy and repeatability but never have i being truly interested in the details. Interesting exposition as usual.

Yeah @sunkanmi02. The essence of technology is embedded in speed, accuracy and iteration!. Thanks for reading through

It would be awesome to see more use of technology in Africa especially in the area of agriculture. But sadly even to make use of not so advanced pieces of machinery like tractors are like a difficult task in most of the continent

Exactly! @greenrun. We have the arable lands to ourselves in Africa. The problem is just to develop and adapt good technologies for use in agriculture. Thanks for your time

We've got it in very great measures. I wish we can harness technology and become the food basket of the world. I can only wish :)

Wishes do come true

W e keep on believing till we get it right

Congratulations @adewumi! You have completed the following achievement on the Steem blockchain and have been rewarded with new badge(s) :

You can view your badges on your Steem Board and compare to others on the Steem Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPDo not miss the last post from @steemitboard:

Vote for @Steemitboard as a witness to get one more award and increased upvotes!

Cool stuff. In my field (microbiology) machine vision can be heavily used to sort and identify cells under a microscope. It’s great to learn of these applications in other fields.

@tking77798. Oh really... That is some cell biology stuff

Thanks for reading through

Congratulations @adewumi! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Vote for @Steemitboard as a witness to get one more award and increased upvotes!