Biotecture

Biotecture:

noun

1. The profession of designing buildings and environments with consideration for their symbiosis and sustainability.

2. A combination of biology and architecture.

Through ‘Biotecture’ we will be exploring alternative architecture and building techniques for their pros and cons as they relate to sustainability and the natural world.

Biotecture is a method of construction that specializes in building symbiotic and sustainable, autonomous structures that utilize natural materials and applications that are customized to support human life, as well as benefit the surrounding environment, with designs adapted and customizable to any climate and/or location.

Biotecture is another term for Eco-Architecture (Ecological Architecture) which is a manner of construction that is symbiotic with the surrounding environment and ecosystem as a whole, as well as sustainable in every aspect. Building life affirming homes that are healthful, engaging technical efficiency and restorative sustainability for integral wellness using renewable and inert materials good for humans and good for environment. We also go so far as to explore and integrate waste management and recycling in creative ways re-using objects that would otherwise go to landfills.

We won’t be promoting any one structure over the others as that depends on your environment and your needs.

There are a number of variations of ecologically friendly building methods, but we will briefly touch upon the main ones in this article.

Here are a few types of Eco-architecture:

– Earthship

– Cob

– Straw-bale

– Adobe

– Bamboo

– Dome

– HempCrete / AirCrete / PaperCrete

Sustainable architecture is architecture that seeks to minimize the negative environmental impact of buildings by efficiency and moderation in the use of materials, energy, and development space and the ecosystem at large. Sustainable architecture uses a conscious approach to energy and ecological conservation in the design of the built environment. The idea of sustainability, or ecological design, is to ensure that our actions and decisions today do not inhibit the opportunities of future generations.

Ecological design is defined as “any form of design that minimizes environmentally destructive impacts by integrating itself with living processes.” Ecological design is an integrative ecologically responsible design discipline.

It helps connect scattered efforts in green architecture, sustainable agriculture, ecological engineering, ecological restoration and other fields. The “eco” prefix was used to ninety sciences including eco-city, eco-management, eco-technique, eco-tecture. It was first used by John Button in 1998. The inchoate developing nature of ecological design was referred to the “adding in “of environmental factor to the design process, but later it was focused on the details of eco-design practice such as product system or individual product or industry as a whole. By including life cycle models through energy and materials flow, ecological design was related to the new interdisciplinary subject of industrial ecology. Industrial ecology meant a conceptual tool emulating models derived from natural ecosystem and a frame work for conceptualizing environmental and technical issues.

Living organisms exist in various systems of balanced symbiotic relationships. The ecological movement of the late twentieth-century is based on understanding that disruptions in these relationships has led to serious breakdown of natural ecosystems. In human history, technological means have resulted in growth of human populations through fire, implements and weapons. This dramatic increase in explosive population contributed the introduction of mechanical energies in machine production and there have been improvements in mechanized agriculture, manufactured chemical fertilizers and general health measures. Although the earlier invention inclined energy adjusting the ecological balance, population growth following the industrial revolution led to abnormal ecological change.

Envirostructure is a portmanteau of the words Environment and Infrastructure. It is a noun that describes all the artefacts needed for application development between the physical infrastructure and the code. It is in effect the tools, techniques and enabling technologies that produce and/or affect symbiotic sustainability.

This is the practice for conducting construction analysis, design, planning, and implementation, using a comprehensive approach at all times, for the successful development and execution of strategy. Eco-architecture applies architecture principles and practices to guide organizations through the business, information, process, and technology changes necessary to execute the strategies, designs and applications.

Arcology, a portmanteau of “architecture” and “ecology“, is a field of creating architectural design principles for very densely populated, ecologically low-impact human habitats.

The concept has been primarily popularized, and the term itself coined, by architect Paolo Soleri. It also appears in science fiction. Authors such as Peter Hamilton in Neutronium Alchemist or Paolo Bacigalupi in The Water Knife explicitly use arcologies as part of their scenarios. Arcologies are often portrayed in science fiction as self-contained or economically self-sufficient. These structures have been largely hypothetical insofar as no arcology, even one envisioned by Soleri himself, has yet been completed, but he posited that a completed arcology would provide space for a variety of residential, commercial, and agricultural facilities while minimizing individual human environmental impact. We will delve into a few methods of biotecture to gain a further understanding of how some of these methods are applied and why.

___________________________________________________________

1. Earthship

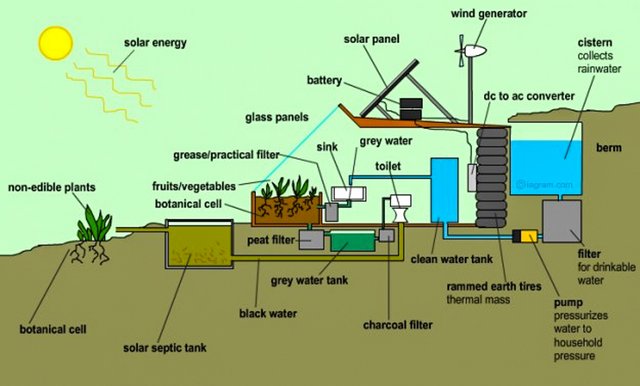

An Earthship is an autonomous ‘machine’ equipped with integrated systems to support life. It is constructed largely using natural and recycled materials and salvaged waste. All variations of Earthship models observe these six design principles: – Thermal and solar heating and cooling: the passive solar design, incorporating a large body of well insulated thermal mass maximises solar gain, and carefully located ‘cooling tubes’ and vent boxes s generate a convection current to cool the space.

– Solar (and wind) power: a customised solar array, charge controller, battery bank and inverter provide power for water pumps, lighting, and the occupants’ electricity needs. The most basic system consists of 2 to 4 PV panels, a charge controller, and 2 car batteries, providing sufficient power to run the basic necessities. More complex systems incorporate both DC and AC circuits, and support conventional household loads.

– Building with natural and recycled materials: rammed earth tyres provide thermal mass, glass and plastic bottle bricks and cans are used for non-load bearing and partition walls and form work, adobe is used for slabs, infill and plastering where appropriate, a variety of materials can be used for insulating and general, non-organic waste is sequestered within the building. These materials are found in abundance globally, and in most places disposal and recycling of these resources is poorly managed.

– Water harvesting: precipitation is captured on the roof, stored in cisterns buried in the berm, and piped through a filtration bank before being pumped to showers, toilets and basins. Used water then enters the grey water loop.

– Food production: botanical cells are built along the inside of the front face of the building and plumbed into the grey water loop, providing naturally lit, temperature regulated and automatically irrigated growing space for year-round plant propagation.

– Contained sewage treatment: a grey water loop delivers water to the planter cells, which is then filtered for flushing toilets, before running out to a contained septic system and evapotranspiration bed.

There term “Earthship” comes from the architect Michael Reynolds. Mike Reynolds graduated from the University of Cincinnati in 1969 with a Bachelor of Architecture. He soon became disillusioned with the path architecture was on and moved to the mesa outside of Taos where he began experimental building with waste and alternative resources. After a lengthy court battle, which is well documented in ‘Garbage Warrior‘, he won the right to test his housing designs through the ‘New Mexico Sustainable Testing Sites Act’, which was signed into law by Governor Bill Richardson on March 15 2007. Reynolds takes his designs all over the world, responding to natural disasters and humanitarian crises, and building for clients from anywhere.

-----------------------------------------------------------------------------------------------

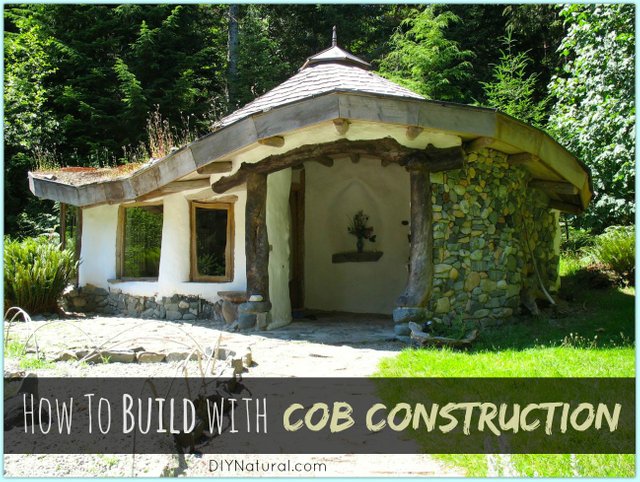

2. Cob

Cob is an ancient earthen building material consisting of clay, sand, straw, water and earth, similar to adobe. It is mixed and applied while still wet by forming it into lumps the size of a loaf or ‘cob’ of bread. These homes are ‘sculpted’ rather than built and are a dream material for artists. If you’ve seen the movie ‘Lord of the Rings’ then you’ve seen the charm of cob.

Have you ever looked at a cliff swallow’s nest and marveled at their cleverness? Nature once again offers us examples to emulate.

The lovely thing about cob is how forgiving it is for the novice. Fireplaces, porches, even furniture can be formed as part of the house.

Cob is an old English word meaning a round mass. It’s comprised of a mixture of sand, soil, straw and water. It differs from adobe in that adobe is dried as bricks or fired in some way to harden the earthen material. Cob on the other hand is mixed and applied while still wet usually by forming it into a lump about the size of a loaf of bread, and stacking one layer upon the other to create the walls. As it dries it becomes almost as hard as stone, and after a coat of lime plaster can stand up to many harsh climates.

Cob homes however are not suitable for areas that experience extreme winters.

In other parts of the globe however, cob has proven itself given the numerous buildings from the 1500’s and up still in use in England today. One thing is certain; this architecture is heavy, so an appropriate foundation to hold it up is absolutely necessary. Cement works fine, but stone foundations (masonry) add a touch of class. Either way it is important to keep the walls from having contact with water from above or below so design it with that in mind, including sloping the ground away from your house and putting in French drains. You know what happens when the ocean tide comes in and takes your sand castle away. These homes are fireproof but water will damage them.

Advantages of Cob:

• Cheap! If you DIY the labour the materials are ‘dirt’ cheap

• Cob is an artistic medium similar to sculpting with clay. Your home will be very unique and artistic

• This building material is fireproof.

• Insulates noise from outside well.

• Suited for passive solar heating

• In dry desert areas it keeps cool in summer and warm in winter

• Cob is forgiving therefore easy to correct mistakes

• Cob plays well with other kids such as adobe or straw bale

• Cobbing makes for a safer work place for those involved

• It’s fun! A great way to invite community to come out and play.

• It’s labor intensive but requires little electricity and/or tools

• A local resource thus low embodied energy

• Durable. You can huff, and puff all day long Mr. Wolf.

• Easy to learn. Even with minimum skills young and old can contribute.

• This building material lends itself to creating curvy walls which allows a better air flow than 90 degree angles.

• Cob allows you to sculpt furniture, chimneys, shelves right into the structure.

• No out-gasing from the building material Cob House on Mayne Island in British Columbia

Disadvantages of Cob • Stone foundations if chosen are labor intensive and expensive if you hire masons.

• While cob is forgiving and simple to use it is very labor intensive. Depending on the status of your back or your wallet that may be a problem.

• Permits. In England they have about a 500 year track record and about 20,000 cob homes are still in use today, however here in Canada…not so much. The good news is it’s not as hard as it used to be. On the Mayne island cob tour here on the coast of British Columbia we saw many lovely straw bale/cob hybrids so if you look to the bottom of the page we’ll hook you up with the right people to get it handled here in the Great White North.

• It doesn’t meet the R20 requirement for insulation

• How it holds up (or doesn’t) in an earthquake is suspect

--------------------------------------------------------------------------------------

3. Straw-bale

Straw Bale hasn’t been around nearly as long as Cob or Rammed Earth, but it has proven to be a very substantial building material.

Straw, traditionally considered a waste product, is a natural non-toxic building material. Baled straw from wheat is wrapped in wire, as the support for walls. It’s a low cost alternative construction material, with excellent insulation properties.

There are two prevalent means of using straw bale as building stuff and they are load bearing walls or infill. Load bearing is just that…bales are stacked one upon the other, holding up the second floor, the roof and a snow load without any effort at all. Compression tests conducted by engineers (as described in ‘Buildings of Earth and Straw’ by Bruce King) show that bale walls could support a load of 10,000 pounds per square foot compared to the standard 2×4 wood framing which can only handle 1,500 lbs per sq. foot. Along with this information I find it very reassuring that if you spike rebar vertically from the foundation all the way to the top unifying plate thus clamping everything tightly together, a straw bale house can resist 100 mile per hour winds.

Using straw for building material takes away the practice of burning it in the field or ploughing it under which has the flip side of being a great way to replenish the nutrients in the soil for next years’ crop.

Straw bale walls must be protected from moisture to avoid mold and rotting. If this occurs it is hell to repair. Sometimes the entire wall must be taken out.

Straw bale walls need a thicker foundation than conventional wood beam homes so that adds to the cost of the project.

While bales are easy to erect, they aren’t the most expensive part of construction in the totality of the project so very likely you won’t save money building a house of this nature.

Due to moisture considerations a straw bale home can’t be built underground or earth bermed thus eliminating the thermal advantages of doing so.

The other method is an infill wall whereby post and beam framing acts like a skeleton supporting the weight of the house. The bales then are stacked between the beams acting as insulation. In both cases you don’t want to skimp on the foundation. Great care must be given to purchase your bales dry and keep them dry as moisture and mold are a concern if they get wet. In an effort to keep them dry suitable overhangs must be present to protect the walls from driving rains, plus toeing up the foundation helps so that the first course of bales is laid minimum 6-8 inches above the earth (or grade). Other preventative measures are moisture proofing the surface of the foundation with something non toxic like the organic sealer DynoSeal since that is where the bales will be touching during the lay of the first course, and applying a layer of waterproofing in between. Last but not least allowing the walls to ‘breath’ so moisture can escape is another consideration which brings us to my favourite part…finishing the wall in plasters.

-----------------------------------------------------------------------------------------------

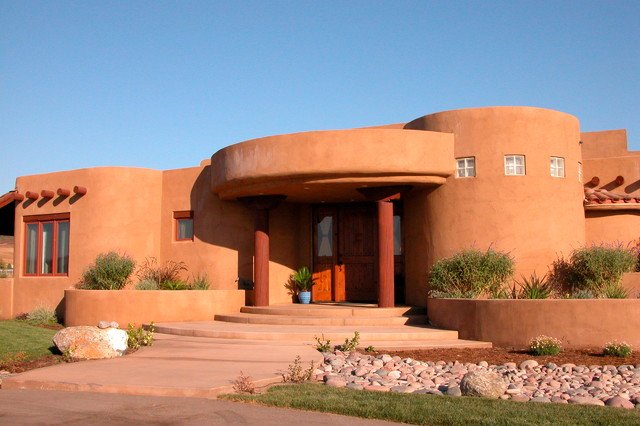

4. Adobe

Nothing can be simpler than mud. It’s been around forever and can be found everywhere on the globe. In fact adobe bricks, which are essentially sun dried blocks stacked and cemented together with mortar, are then either left alone or covered over with an earthen plaster (so that’s mud to the power of three). Adobe huts have been around 5000-6000 B.C.

Perhaps the most obvious vulnerability of this building material is its lack of resistance to water. In arid parts of the world this may not be a problem, but waterproofing adobe walls from streams of water, free standing water or seepage from underground becomes imperative no matter which foundation you ultimately go with, although here in the western world poured concrete is generally the one of choice.

Adobe bricks can be made to whatever size you want them to be. Adobe bricks are made from mud containing a ratio of approx. 20% clay and 80% sand, although building codes in your area may require a higher percentage of clay as it acts as the binder. Of course getting the ratio right is important in that too little clay and you’ve got cracking whereas too much sand and the bricks become brittle and less resistant to weathering.

There are many variations on how to make adobe bricks. Some people add chopped straw as it creates a lighter brick to handle. Others use an asphalt emulsion (oil by-product) which makes them water proof. However this contains some serious chemicals that smell and are potentially harmful which are seen by many as unnecessary when outside walls can be plastered to protect from moisture instead. Some people further south (Mexico) fire the bricks in a kiln for two days which makes them harder than the air dried variety, but they also absorb more moisture which can accumulate inside the brick and flake during contraction and expansion. Pressed earth blocks made by machines (with a little cement added) may lack the charm of individual hand made bricks, but on the practical side they can compress a really strong block, of a consistent size, for use almost instantly in both wet and colder climates.

Of course no matter which blocks you use they will need to be ‘cemented’ together with an earthen mortar made from the same mud as the bricks minus the little stones and organic matter.

------------------------------------------------------------------------------

5. Bamboo

A member of the grass family, bamboo is a versatile and plentiful building material found all over the planet. It can be used 5 years after planting. From building the structural portions of homes to your flooring, bamboo is a fast growing natural resource worth considering in your construction plans.

Bamboo is as versatile a building material as it is virulent growing. You can use the thicker portions for framing or structural needs including floors, beams n’ rafters, and roofing whereas the small stuff goes into non-load bearing uses like wall/ceiling covers, mats and even roof shingles.

Its hard to believe that a reed can be used to construct very sturdy scaffolding or that it is awesome at pinning courses of straw bales together, but there is a multitude of uses for this building stuff and the list is growing. Although building houses out of bamboo is better known in Asia than North America its being rediscovered in hybrids all over the world today.

Bamboo can be utilized as a building material as for scaffolding, bridges and houses. Bamboo, like true wood, is a natural composite material with a high strength-to-weight ratio useful for structures. Bamboo has a higher compressive strength than wood, brick or concrete and a tensile strength that rivals steel.

Bamboos are some of the fastest-growing plants in the world, due to a unique rhizome-dependent system. Certain species of bamboo can grow 35 inches/890 mm within a 24-hour period, at a rate of 0.00003 km/h (a growth of approximately 1 millimeter (or 0.02 inches) every 2 minutes).

Disadvantages of Bamboo

-If you don’t know your species don’t try growing your own to harvest for building. It can be very invasive and take over the area.

-Bamboo’s greatest challenge is weathering. It doesn’t stand up well to water and needs chemical treatment to protect it.

-Bamboo therefore breaks down quickly if it comes in contact with wet or damp soil.

-Bamboo is highly combustible.

-The reed tapers making it more difficult to build with than processed lumber.

-Reeds vary in size from one to another making it a challenge to build with.

-Grass is hollow and round inside making it more of a challenge than identical pieces of lumber.

-----------------------------------------------------------------------------

6. Dome

Based on design, Domes resemble the simple shape of an Egg, which is structurally very strong.

The construction material you choose, such as wood, metal, or concrete, will dictate the strength of your structure, and can be Fire, Water and Wind resistant.

Monolithic Dome structures, known to be one of the strongest, cannot be destroyed by most natural or man made disasters. They are impervious to Hurricanes and Tornadoes. In cases of fire, even though contents that are flammable will be lost, the basic structure can remain unaffected.

Since a circle contains the most square footage of any design shape, the Dome structure allows for a wide variety of floor plan designs because they need no Interior Support.

This same shape offers Energy Efficiency in the cost of running and heating.

A Dome is a structure built to resemble the hollow upper half of a ball. The Sphere can take on several round shapes from a half a grapefruit to a bulbous onion, however it’s still a sphere.

Dome construction goes back millennia. Remains of mammoth tusks/bones used for small dwellings presumed to be domes were dug up by a Ukrainian farmer in 1965 while he was digging in his cellar. The tusks dated back 15,000 to 20,000 years ago. That’s how far back we are talking about. Domes are found all over the world made out of a Multitude of Building Materials as mammoth tusks are hard to get a hold of today (kidding) There’s an insane number of variations on this theme so one might come to the conclusion it’s a damn clever structure. Indigenous peoples from all over the world have been building them with whatever local material as available.

The Native Americans had Wigwams made from branches and hides, while the Inuit made Igloos from blocks of snow, and the Himba people of Namibia made a similar igloo shape out of wattle and daub as they were desert dwellers.

FEMA rates them as “near-absolute protection” from F5 Tornadoes and Category 5 Hurricanes. Recently, a number of monolithic domes constructed using MDI ( Monolithic Dome Institute ) techniques have survived major disasters. In fact in 2003 one such domed government building in Bagdad, formerly a part of Saddam Hussein’s regime, was hit by a (2,300 kg). bomb, and apart from the hole made by the entry of the bomb, it remained structurally sound.

---------------------------------------------------------------------------

7. Hempcrete / Aircrete / Papercrete

-Hempcrete or Hemplime is bio-composite material, a mixture of hemp hurds (shives) and lime (possibly including natural hydraulic lime, sand, pozzolans) used as a material for construction and insulation. It is marketed under names like Hempcrete, Canobiote, Canosmose, and Isochanvre. Hempcrete is easier to work with than traditional lime mixes and acts as an insulator and moisture regulator. It lacks the brittleness of concrete and consequently does not need expansion joints. The result is a lightweight insulating material ideal for most climates as it combines insulation and thermal mass.

Like other plant products, hemp absorbs CO2 from the atmosphere as it grows, retaining the carbon and releasing the oxygen. Theoretically 165 kg of carbon can be absorbed and locked up by 1 m3 of hempcrete wall during manufacture. Furthermore the carbonation of the lime during curing adds to this effect as lime turns to limestone.

The typical compressive strength is around 1 MPa, around 1/20 that of residential grade concrete. It is a low density material and resistant to crack under movement thus making it highly suitable for use in earthquake-prone areas. Hempcrete walls must be used together with a frame of another material that supports the vertical load in building construction, as hempcrete’s density is 15% that of traditional concrete.

-Aircrete, otherwise known as Autoclaved aerated concrete (AAC), autoclaved cellular concrete (ACC), autoclaved lightweight concrete (ALC), autoclaved concrete, cellular concrete, porous concrete, Aircrete, Hebel Block, and Ytong, is a lightweight, precast, foam concrete building material invented in the mid-1920s that simultaneously provides structure, insulation, and fire- and mold-resistance. AAC products include blocks, wall panels, floor and roof panels, cladding (façade) panels and lintels

AAC is a highly thermally insulating concrete-based material used for both internal and external construction. Besides AAC’s insulating capability, one of its advantages in construction is its quick and easy installation, because the material can be routed, sanded, or cut to size on site using standard carbon steel power tools.

AAC is well suited for urban areas with high rise buildings and those with high temperature variations. Due to its lower density, high rise buildings constructed using AAC require less steel and concrete for structural members. The requirement of mortar for laying of AAC blocks is reduced due to the lower number of joints. Similarly, the material required for rendering is also lower due to the dimensional accuracy of AAC. The increased thermal efficiency of AAC makes it suitable for use in areas with extreme temperatures, as it eliminates the need for separate materials for construction and insulation, leading to faster construction and cost savings.

Even though regular cement mortar can be used, most of the buildings erected with AAC materials use thin bed mortar in thicknesses around ⅛ inch, depending on the national building codes. AAC materials can be coated with a stucco or plaster compound to guard against the elements, or covered with siding materials such as brick or vinyl.

-Papercrete is an incredible building material that is lightweight, amazingly insulate, and low cost. Any paper can be used, including old newspapers, phone books, and cardboard.

Papercrete can be formed into bricks by simply pouring the pulpy mixture into molds, then setting them into the sun to dry, similar to Adobe bricks. Once dry, the bricks can be used like traditional bricks, using more papercrete as the mortor to hold the bricks together.

Papercrete is recycle-reusing old paper in a slurry of sand and cement mixed and poured into molds to make any size and shape brick you please. It’s cement ‘light’, all the insulated properties you want without the weight.

The recipe goes as follows:

60% paper (newspaper/cardboard/magazines), 30% sand and 10% cement.

Disadvantages of Papercrete:

• You want to build a what? Getting permits

• Non-resistance to water

• Experimental – you are the guinea pig

• Not too many construction crews around doing this yet

• Codes not yet written for this method

• Not suitable for the rain forest or wet climates

____________________________________________________________

Zero Carbon Housing and Zero Energy Housing are terms used interchangeably to define single family dwellings with a very high energy efficiency rating. Zero Energy Housing requires a very low amount of energy to provide the daily needs and functions for the family occupying the home. A zero carbon home has a yearly net carbon footprint of zero. The carbon footprint is the total measure of all greenhouse gas emissions generated or produced directly or indirectly by activities in the home such as heating the home or running an appliance, personal activities such as driving a car, broader services such as the use of public transportation or air travel, and individual consumption of food and other products.

A home’s carbon footprint consists of the sum of two parts, the primary footprint and the secondary footprint, expressed in units of metric tonnes of carbon dioxide equivalent(CO2e).

-The primary carbon footprint is a measure of the CO2 emissions from the direct consumption of fossil fuels for energy consumption and transportation.

-The secondary carbon footprint is the measure of indirect CO2 emissions related to the manufacturing process of products used in the home and eventual decomposition of products. Examples of the parts that make up the secondary carbon footprint are the manufacturing of clothes, cars, and furnishings, as well as recreational activities by the inhabitants.

The calculation of the carbon footprint becomes detailed when considering secondary factors. Secondary factors involve the home’s occupant lifestyle such as diet, foods are consumed (an example being conventional agriculture compared to agroecological cultivation), frequency of yearly air travel, commuting mileage to and from work, school, etc., use of public transportation, and number, type, and use of private vehicles.

Secondary factors also include fashion or type of clothes purchased and worn, frequency of recycling, recreational activities and use of financial and other services throughout a given year. The frequency of airline flights in a year is considered due to the amount of fuel consumption and other energy usage and emissions generated by one flight. A person that travels frequently may have a significantly bigger carbon footprint than someone who flies once a year for a vacation. The emissions for an individual flight are calculated by using the greater circle method.

First, the distance between airports is determined. Then calculations are completed to account for indirect distances and by an emissions factor in relation to the type of flight (international or a short flight, and what class seating the person is in). Another contributing factor to a person’s carbon footprint is their personal vehicle which includes the type of car driven, the efficiency or miles per gallon (MPG) rating, and the amount of miles driven each year. The frequency of public transportation used by an individual, miles travelled on public transportation and the type of public transportation used such as bus, train, or subway contributes to their carbon footprint as well. Other factors, as trivial as they might seem, are included in the calculation of a person’s carbon foot print to include things such as the type of diet.

Other factors include the purchase of local and /or agroecologically grown produce vs. imported items, the latest clothes fashions vs. more conventional purchases, buying individually packaged products vs. buying in bulk, recycling activities, and the types of recreation such as carbon-free activities like hiking and cycling or carbon-intensive activities like skydiving or boating.

Biotecture can play a considerable role in environmental governance. These ecologically symbiotic and sustainable structures are capable of serving the same everyday functions of a home / building against changing environmental conditions and are a form of engineering resilience. Engineering resilience is a part of adaptive governance. Adaptive governance is the idea that sustainability can be achieved by adapting to changes instead of changing something completely.

-Zero Carbon homes allow humans to adapt to the increasing global temperature. These types of homes make it possible for people to survive without the use of declining levels of fossil fuels, protects the inhabitants from food shortages, and water contamination.

-Zero carbon homes can provide resilience to the changes from the upset of a tipping point in dynamic stability. In this case “tipping point” represents the dangerous aspects of climate change. When a tipping point occurs the system would be subjected to a new domain of stability and the characteristics of stability will have changed. The system will have entered into a new “domain of attraction” and the system will be attracted to a new resting place. In the idea of this, the height of the valley that the “domain of attraction” is in determines the amount of stress or disturbances needed to force the system into another valley or “domain of attraction”.

-Zero carbon homes provide engineering resilience to this event because they will be able to cope with the disturbances that occur. Exactly when these “tipping points” are going to occur is almost impossible to know and difficult to predict. They represent non-linear change, making it difficult to predict or prepare for.

Written by: Quae Frei

two votes! are you fucking kidding me! this is rad! upvote for sho!!

you built any of em?

Yes, i have participated in everything here except for aerocrete and hempcrete.

Aerocrete you really have to make yourself, i have just yet to make the necessary apparatus for production, which is even DIY and pretty simple.

The hempcrete is actually a bit difficult to come by depending on location or resource ability, most of the projects i do or have done are volunteer based and largely DIY with little to no resource ability.

I appreciate the support and excitement!!!

It makes me very happy to see others excited by these and other solutions we have available today!!

I have another article here on steemit about agroecology as well, and if you like biotecture then i am sure will enjoy its counterpart!!!

Thank you again!!!

Be well and nourished!!

Deep article. May I suggest that next time you break it down into a series of articles? It would be much easier to read and comment on it that way.

Question: what do you see the role of biomimicry in architecture? I didn't see anything written about it.

I will probably have more questions as I dive deeper into this. I work with nature-inspired innovations, so I am very interested in many of these topics!

Congratulations @quae-frei! You received a personal award!

Click here to view your Board

Congratulations @quae-frei! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Vote for @Steemitboard as a witness to get one more award and increased upvotes!