Insight into the world of crude oil: How much do you know about the famous, everyday product? – RECOVERY METHOD AND REFINING OF CRUDE OIL

Over the last few posts of mine, I started digging on how popular crude oil is, how it is been located or explored, the wells that we have and how they are classed, the processes involved in drilling and some other basic information. I am happy to be writing today again after a very long time. I hope this meets you well? In order to know if this series has been helpful, kindly drop your comments or feedbacks; I would well appreciate them.

I’d still very much site Nigeria as my reference; it is believed there is so much money and profit in the oil and gas sector but ample details of every inch process in the sector are left out. This is a simple and straightforward article that is aimed at showing a breakdown of part of the processes involved. I hope this is well enough practical and readable.

To the business of the day…

In oil drilling, there is a probability that a well been located and noted as a potential oil well may not fully yield what is expected of the exploring company. The analogy is quite simple while this should help. Imagine the profit an organization makes from exploring a well is about fifty million USD ($50,000,000) and all they spent to make sure the operation was a success amounts to about hundred million USD ($100,000,000). This is, in fact, spending more (twice) than what their gain truly is. This, in the business world, is called a loss and it’s termed a failure.

A company (exploration or oil and gas) before setting out to start any of the processes in oil production would count her cost and also predict what their likely returns would be. ‘This is how to truly ensure things don’t go south’. (I have a feeling the quoted sentence is a military word as watched in a movie, it could be a general sentence though). The only major way things could go south is by digging of rock to locate wells that won’t cater or cover for the cost. The term Oil Recovery then becomes all important to avoid running at loss.

So, what then is a recovery of oil and how is it feasible/achieved?

Think of a money recovery (more like loot recovery- Abacha’s), it involves getting back what is yours or what was stolen from you but believed to be yours. Oil recovery is more like it, just that nobody stole the oil from you, as a matter of point, the reverse is the case.

There are three major recoveries in oil which are the primary, secondary and the tertiary recovery.

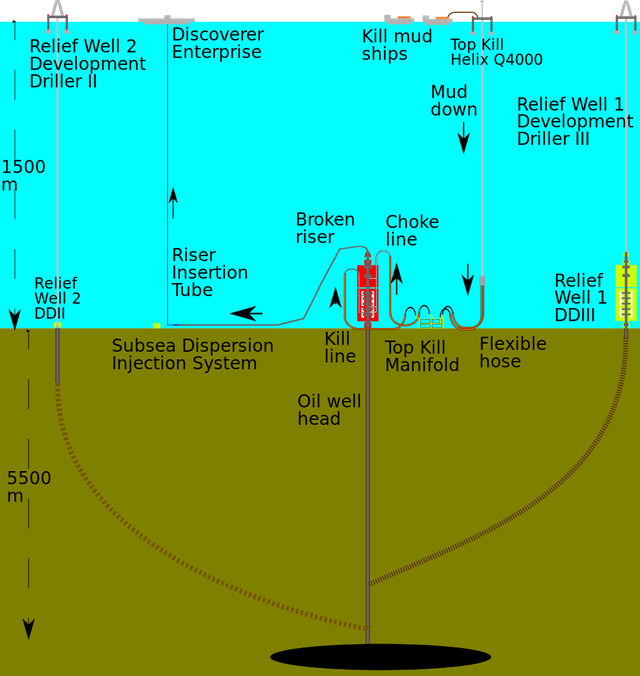

The primary mode of recovery accounts for the natural drive that comes from the well. A typical well, under normal circumstances, has its own pressure embedded in it. This pressure is what pushes the crude oil to the surface or directs it to where intended. The return on primary recovery is usually low and may be in the range of 5-15% of the total oil in the well; hence, the need for an upgrade in recovery. This then leads us to the secondary recovery.

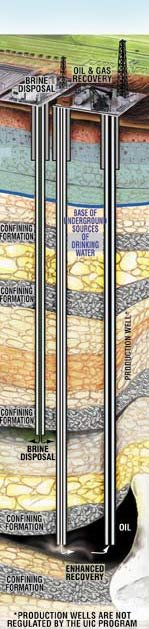

The secondary recovery is a measure that is understood to come to play when primary recovery is of little or no help. As human age increase, so does wells’ mortality clock clicks. Nothing last forever, you know? The sad thing about well aging is a reduced performance in the form of their pressure. Once the pressure is down, oil can no longer be forced out. The secondary recovery uses methods like liquid injection, pumps, and fracturing. Liquid injection works by injecting water as a force or to provide pressure for the well and can also be called fracturing. In injecting or fracturing a well, a large amount of water or liquid is released at a high pressure into the well to force the crude oil out. The oil gathered from a well via a secondary recovery method stands at 30-45% of the total content.

The tertiary finally is another recovery aimed at fully maximizing the potentials of a well. Here, chemicals and heat are used. Basic examples include acidizing and fire flooding. Acidizing a well basically means using the aid of acid to influence the returns from a well. An acid such as hydrochloric acid (HCL) was first used but currently, formic acid, acetic acid and hydrofluoric acid are been combined with the hydrochloric acid to prevent corrosion and keep its reaction in check. Hydrochloric has to be kept in check because of its reactivity. Fire flooding is another example; a thermal-based recovery where oxygenated gases or air is injected into the well and a portion been lit. By heating, the gases from the fire reduce the viscosity (resistance of a liquid to shear forces) of the oil thereby aiding it to flow easily. Gases from the fire also increase the pressure in the liquid.

A rare method called the oil-eating bacteria is pacing so hard to become fully known. It can be thought of as environmentally friendly and economically feasible. The bacteria in view breaks large hydrocarbon into small fractions in which make the viscosity as low as possible. Once the viscosity is low, the movement or flowing of crude oil becomes easy.

Having gotten enough on how important oil recovery is, shall we take a look at the separation technique(s) used to break the crude oil down to single compounds that meet every engine’s specification or every household usage?

What is the separation of crude oil and why is it important?

The analogy and breakdown of crude oil are these; in a typical well that has crude oil, the crude oil has fossil fuel in gaseous state dissolved in it. The fossil fuel later takes the turn of states or forms of matter- liquid, solid and gas of hydrocarbons. Aromatic hydrocarbons, alkanes (paraffin), organic compound like nitrogen and oxygen and cycloalkanes (naphthenes) are what make up the hydrocarbons.

In chemistry, we were told or learnt that separation techniques included the processes whereby a solution or mixture can be converted into more than one distinguishable product. A post by @addempsea here a while back explicitly explains most separation techniques used. You may want to read up the post to see that the high school lessons you thought were jargons are actually very important.

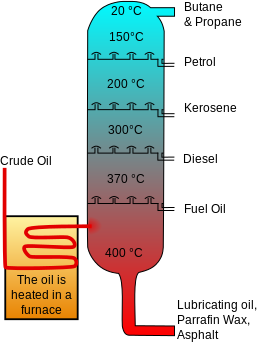

Refining is the professional term used in place of separation and it is separating of the several constituents or compounds from the crude oil by a method called fractional distillation.

What is termed fractional distillation?

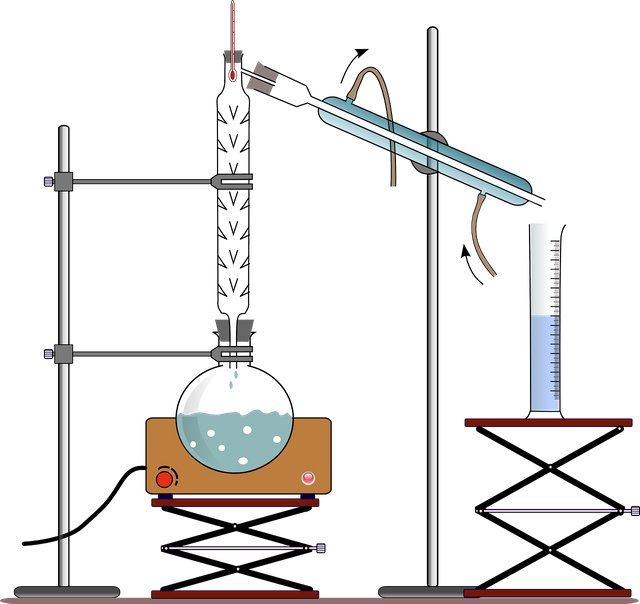

Fractional distillation is a separation technique which involves using heat to distinguish or separate various components in a chemical solution like the crude oil into fractions. These fractions are determined by their boiling points. The boiling point plays a major role in fractional distillation in that the compounds to be separated have their respective boiling points. Once a boiling point for one is exceeded, the product is likely not gotten. Let me get you cleared on what boiling point is; it is the temperature at which a liquid boils. As crude oil boils, it moves from liquid to vapor or gas and this ensure that the right compounds are correctly separated from the mixture.

Why is refining important?

It is sort of clear from the explanation of fractional distillation why refining is important but I’d go over it for emphasis sake. Crude oil is basically a mixture of large or numerous organic molecules. Since the numerous organic molecules can’t be used that way, it has to be broken down to fit into different areas intended for it. Thus, refining makes it possible to use the original crude oil in more places to serve the everyday need.

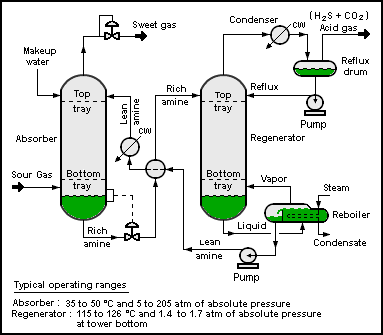

The process involved in refining crude oil known as fractional distillation separates the products into fractions. The crude oil is heated in a crude oil distillation unit which uses a big furnace to distill it to a temperature of 398oc. After heating, mineral salt is removed from the oil and run into a fractionating column. In this column is where different product assumes their position based on their boiling point (remember that the heating is still on). A product assuming a position at the top of the fractionating column means it has a low boiling point and such products are kerosene, butane and petrol. Invariably, the products at bottom of the fractionating column have higher boiling points than those on top and such products are fuel oil and diesel. In order to ensure the crude oil is cooled, an overhead condenser is used. This condenser can be a water-based or an air-based condenser. It cools the crude oil and in between, new oil comes in as the processed one rush out to enable the process of cooling as well.

After the crude oil has been stored and fully processed i.e separated into categories and freed of any polluted material, the products can then be shipped to various depots. The depot serves as the housing unit for the different products. A depot can house over 4 products. Eterna PLC where I worked for a while had gigantic tanks that held Petrol, Diesel, Kerosene, Aviation turbine kerosene and engine oils.

Wrap-up

This would go as a free ~byte~. I have talked greatly about how a well is noted to have oil, drilling, and so on. How does the oil reservoir or well form? It can’t be a mystery! Truly, it isn’t. There are conditions that must be met before we can have a reservoir. These conditions are split into three and they are

- A rock known as the source rock (A source rock is a rock which hydrocarbons can be gotten from. There are also three types of the source rock which are, Type I, II, and III) must be able to be heated to influence the oil in it.

- A reservoir must be in place to hold the oil and finally

- For an oil field to form there must be a mechanism in place that keeps the oil from flowing away. What is understood by an oil field is the ability of a permeable rock to hold the crude oil without letting the product go away.

Refining crude oil can have a whole lot of products. The lubricant is an example of its product and is used in the production of the famous engine oils and greases; alkene is another product which is useful in the production of plastics. Other products are but not restricted to asphalt, paraffin wax, bitumen and sulphuric acid.

You may now consider why this industry, the oil and gas industry is the highest force to reckon with in all the existing sectors.

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

I'm a proud member of @promo-mentors where you get mentored and guided on how to make quality posts on steemit amongst other benefits. Do join us on discord. We anticipate your arrival.

Sources

Fractional distillation

Location and extraction

Documentation

Oil refinery

Chemical industry

From a fellow Nigerian, I say "oil money is cooool money". Oil is actually one of the few natural resources that can sustain the economy of a whole nation.

The.money invested is one thing though. Imagine spending millions of Naira, and what you get is a "

no show". Hurtful it'll be. Nice

Post though

Exactly! You get a huge profit from every processes involved in crude oil. We'd have praised the resource more if we only had its profit been channeled well. Thanks for reading.

@michaelwrites I knw refining crude oil is complex process after a great efforts we get products of petroleum

Posted using Partiko Android

Yes, you are right.

This is all new information to me @michaelwrites. And you certainly met your promise: you made this a practical and readable content, even for novices like me.

Besides learning all the processes oil goes through before it becomes something useful for everyday life I also found interesting to learn a little about the financial side of this industry!

Thank you for taking the time to inform us all about this :)

Thank you @abigail-dantes for finding the post practical enough; this trounced all what I'd sum the post to be on it readability. I've myself been drawn to this particular sector of all because of the profit and popularity attached to it.

You may want to make this practical enough by visiting a refinery or going over to a depot. 😃

This post has been voted on by the steemstem curation team and voting trail.

There is more to SteemSTEM than just writing posts, check here for some more tips on being a community member. You can also join our discord here to get to know the rest of the community!

Congratulations @michaelwrites! You have completed the following achievement on Steemit and have been rewarded with new badge(s) :

Click on the badge to view your Board of Honor.

If you no longer want to receive notifications, reply to this comment with the word

STOPCongratulations @michaelwrites! You have completed the following achievement on Steemit and have been rewarded with new badge(s) :

Click on the badge to view your Board of Honor.

If you no longer want to receive notifications, reply to this comment with the word

STOPCongratulations @michaelwrites! You have completed the following achievement on the Steem blockchain and have been rewarded with new badge(s) :

Click here to view your Board of Honor

If you no longer want to receive notifications, reply to this comment with the word

STOPDo not miss the last post from @steemitboard:

Congratulations @michaelwrites! You received a personal award!

Click here to view your Board

Congratulations @michaelwrites! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Vote for @Steemitboard as a witness to get one more award and increased upvotes!