Commitment of Power Plants Based on Efficiency and Least Cost of Operation

Economic Operation of Power System

The economic operation is very crucial for a power system to return a profit on the capital invested. Power companies cannot afford to operate at just any cost because of the rates fixed by the regulatory bodies and also the need to conserve fuel puts additional pressure on them.

The utility company needs to operate its generators at maximum efficiency to reduce to a minimum the cost per kilowatt-hour of power generated. This operation ensures that consumer gets the power at minimal cost. The capital invested by the power company in the process of delivering that kilowatt-hour in the face of ever-changing and rising prices for fuel, labour, supplies and maintenance will drop to the barest minimum.

Being efficient is not enough, but the emphasis is on operating at the minimum cost taking into consideration the fuel cost, cost of labour, supplies and maintenance.

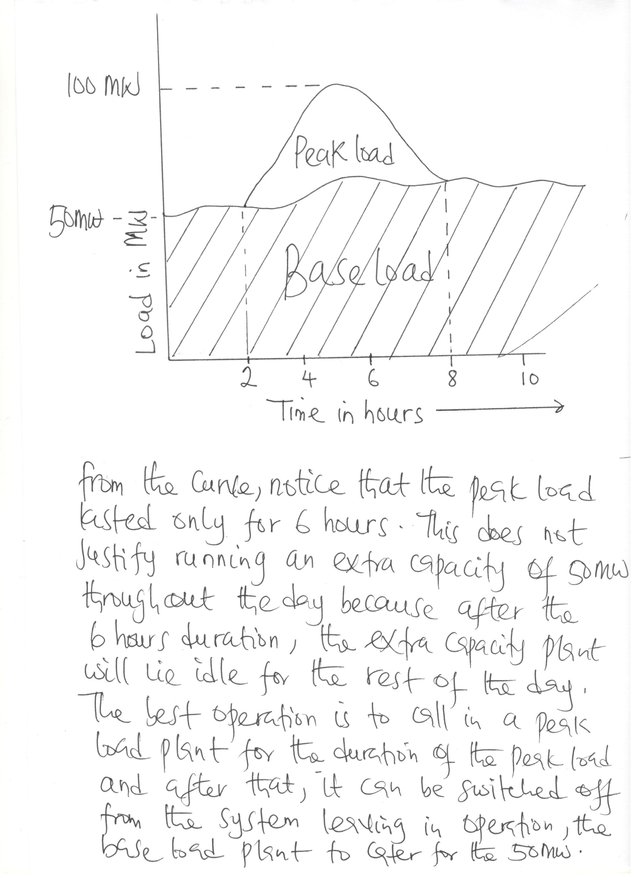

For example, if the load represented by the figure below is to be supplied from one power plant only, it then means that the installed capacity of the plant should be equal to the peak load or more. Such a power plant will be uneconomical. Since the peak load occurs only for a short duration of time (between 2 pm and 8 pm) in a day and therefore the capacity equal to the difference of the peak load and the base load would remain idle for the major portion of the year.

Hence, such a power load should not be supplied from a single power plant. There would be some power stations providing the base load and others, possibly of the different type supplying the peak load.

The operation economics involving power generation and delivery can be subdivided into two parts-One covers the minimum cost of power production known as economic dispatch while the other deals with minimum loss delivery(losses in the transmission line) of the generated power to the loads.

For any specified load condition, economic dispatch determines the power output of each plant (and generating unit within the station) which will minimise the overall cost of fuel needed. The economic dispatch coordinates the production at all power plants operating on the system.

The classical approach to economic dispatch affords series of steps which include:

• The study of the most economical distribution of the output of a plant between the generators or units within the plant.

• The economic scheduling of the plant outputs for a given loading of the system without considering transmission losses

• The transmission loss is expressed as a function of the output of the various plants under consideration.

• Determination of how the output of each of the plants of a system is scheduled to achieve a minimum cost of power delivered to the load.

Because the total load on the power station varies throughout the day, coordinated control of the power plant outputs is necessary to ensure generation-to-load balance so that the system frequency will not deviate much from the 50Hz obtainable here in Nigeria.

Also due to daily load variation, the utility has to decide by economics which generator to start up, which to shut down and the sequence or order in which to follow.

The computational procedure for making such decision is called Unit Commitment.

Distribution of Load Between Plants

At the experimental stage of economic dispatch, it was the usual practice to supply power from only the most efficient plants at light loads.As the load increases, the plant will continue to provide power to the load until the point of maximum efficiency of that plant is reached.

Then, if the increase in load persists and exceeds the point of maximum efficiency and capacity of the first plant in operation, it therefore means that the next most efficient plant would come into operation and feed power to the system, and a third plant would not be called upon until the point of maximum efficiency of the second plant is reached. Even with transmission losses neglected, this method proved to be ineffective in minimising the cost of operation of the plants.

The economic distribution of load between the various generating units consisting of different types of power plants is determined by considering the variable operating cost of the unit and must be expressed regarding the power output. Fuel cost is the principal factor in fossil-fuel plants, and cost of nuclear fuel can also be expressed as a function of the output.

The reason behind limiting this analysis to the economics of fuel cost is for simplicity since we can easily incorporate all other cost which is a function of the power output into the expression for fuel cost.

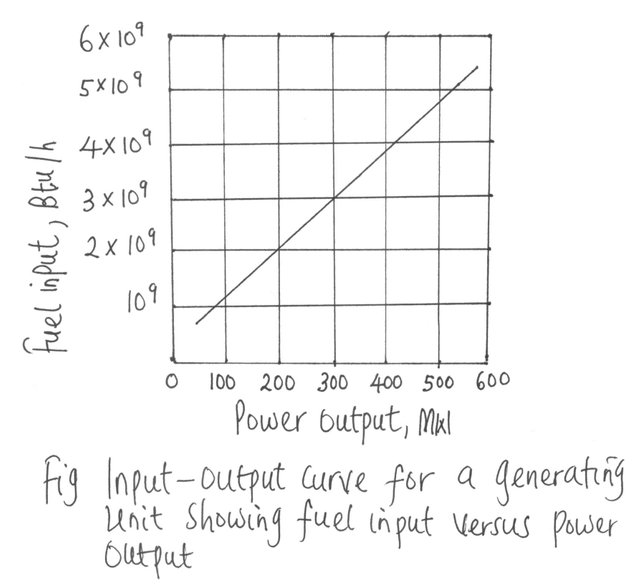

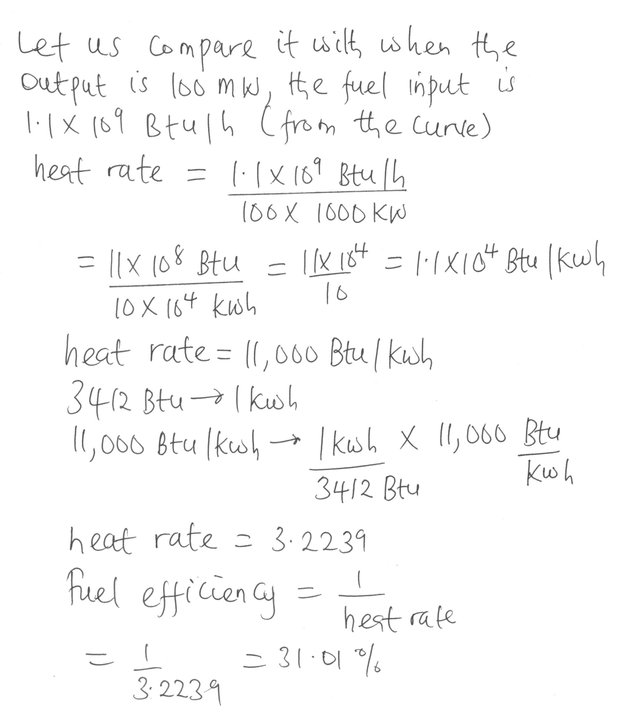

Consider the input-output curve shown in the figure below which is a plot of fuel input for a fossil-fuel plant in British thermal unit (Btu) per hour versus power output of the unit in megawatts. The ordinates of the curve are converted to dollars per hour by multiplying the fuel input by the cost of fuel in dollars per million Btu.

If we draw a line through the origin to any point on the input-output curve, the slope can be expressed in millions of Btu per hour divided by the output in megawatts, or the ratio of fuel input in Btu to energy output in kilowatts.

This ratio is called the heat rate, and its reciprocal is the fuel efficiency. Thus, lower heat rates imply higher fuel efficiency

Maximum fuel efficiency occurs at that point on the curve from the origin to a point on the curve is a minimum, that is, at the point where the line is tangent to the curve.

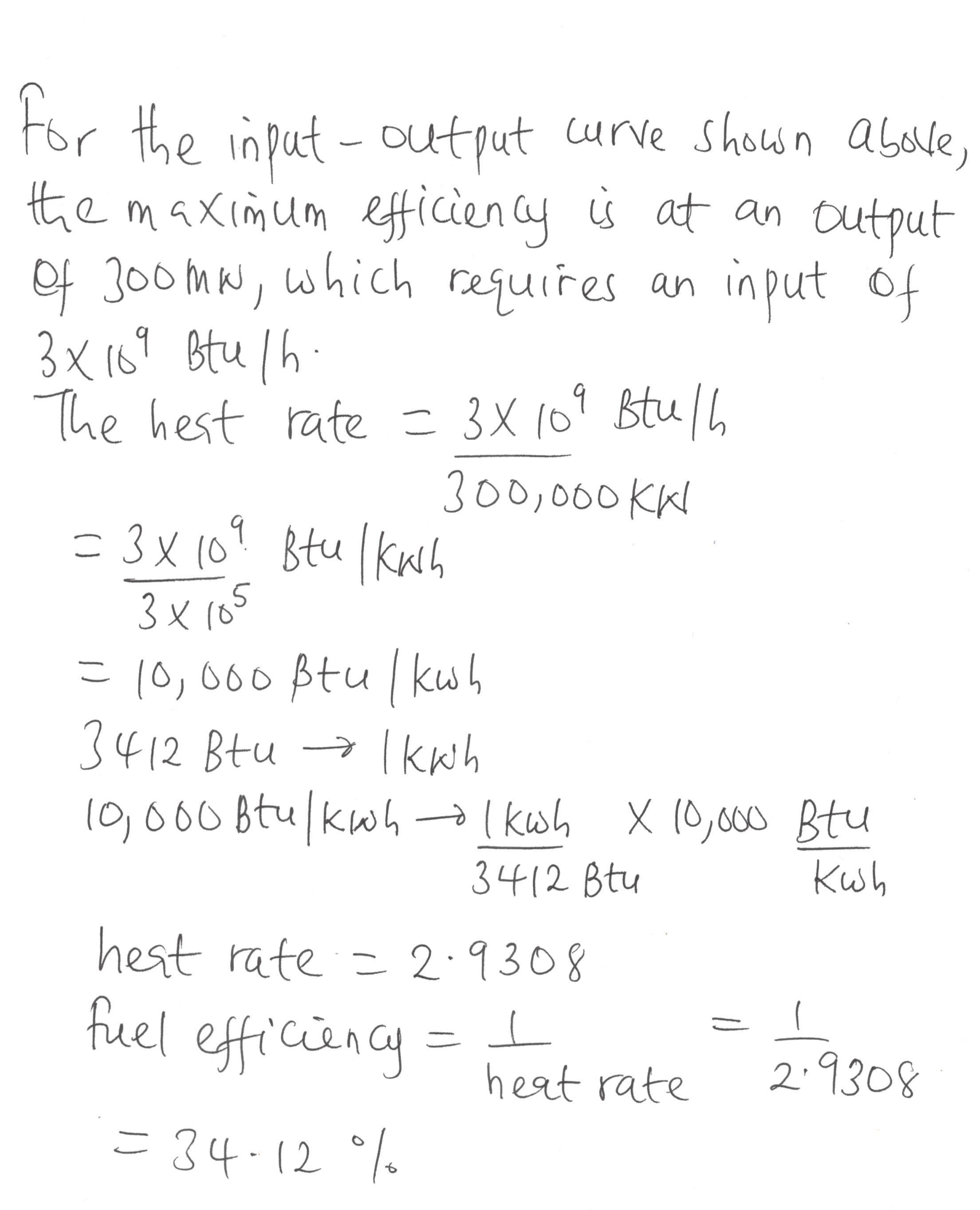

For the unit shown in the figure above, the maximum efficiency is at an output of approximately 300MW, which requires 3×109 Btu/h. The heat rate is 10,000, and since 1kWh = 3412 Btu, the fuel efficiency is approximately 34.12%. By comparison, when the output of the unit is 100 MW, the heat rate is 11,000 Btu/kWh and fuel efficiency is 31.01%. The steps are as shown below:

The criterion for distribution of the load between any two units is based on whether increasing the load on one unit as the load is decreased on the other by the same amount results in an increase or decrease in total cost.

The principle of economic dispatch which guides the distribution of load among the units within one or more plants in a system is often based on incremental fuel cost.

For instance, suppose that two units supply the total output of a particular plant and that the division of load between these units is such that the incremental fuel cost of one is higher than that of the other. Now suppose that some of the load is transferred from the unit with the higher incremental fuel cost to the unit with lower incremental cost.

Reducing the load on the unit with higher incremental cost will result in a greater reduction of cost than the increase in cost for adding the same amount of load to the unit with the lower incremental cost. The transfer of load from one to the other can be continued with a reduction in total fuel cost until the incremental fuel cost of the two units is equal.

The same reasoning can be extended to a plant with more than two units. The economic division of load amongst units within a plant is ensured by adopting the rule that all unit must operate at the same incremental fuel cost.

In determining the economic distribution of load between plants, there is need to consider losses in the transmission lines. In as much as the incremental fuel cost at particular plant-bus may be lower than that of another plant for a given distribution of load between the plants, the plant with the lower incremental cost at its bus may be much farther from the load centre.

The losses that will arise in the transmission line for the plant having the lower incremental cost may be so great that the economy may dictate lowering the load at the plant with the lower incremental cost and increasing it at the plant with higher incremental cost. This is because the losses in the transmission line have eroded the advantage of the plant operating at lower incremental cost because it is far from the load centre.

The second plant with higher incremental cost has the advantage of overall minimal cost due to its nearness to the load centre and as such has very minimal transmission line losses.

Thus, there is need to coordinate transmission loss into the scheduling of the output of each plant for the maximum economy at a given level of system load.

Automatic Generation Control

Many generating companies exchange power with some other generating stations. This exchange is because, at a point in time, the peak occurs at different times for the two different stations serving a different set of consumers.

This exchange takes place through tie lines. The tie lines allow the sharing of generation resources in emergencies and economies of power production under normal conditions of operation.

For control, the entire interconnected system is subdivided into control areas which usually conform to the boundaries of one or more companies. The net interchange of power over the tie lines of an area is the algebraic difference between area generation and area load (plus losses).

The load on the power system varies randomly as the hours of the day wears on and is often dictated by the activities of the consumer. This load variation could lead to frequency changes which make an accurate forecast of real power demand quite difficult.

The mismatch between real power generation and load demand (plus losses) throughout the daily load cycle causes kinetic energy of rotation to be either added to or taken from the online generating units, and frequency throughout the interconnected system varies as a result.

The tie line ensures that frequency can be balanced from either side depending on the utility that with a comparative advantage at the time of frequency variation.

Each control area has a central facility centre, which monitors the system frequency and the power flows on its tie lines to the neighbouring area. The deviation between desired and actual system frequency is then combined with the deviation from the scheduled net interchange to form a composite measure called the area control error, or otherwise called ACE.

To remove the area control error, the energy control centre sends command signals to the generating outputs to restore the net interchange power to the scheduled values and to assist in restoring the system frequency to its desired value.

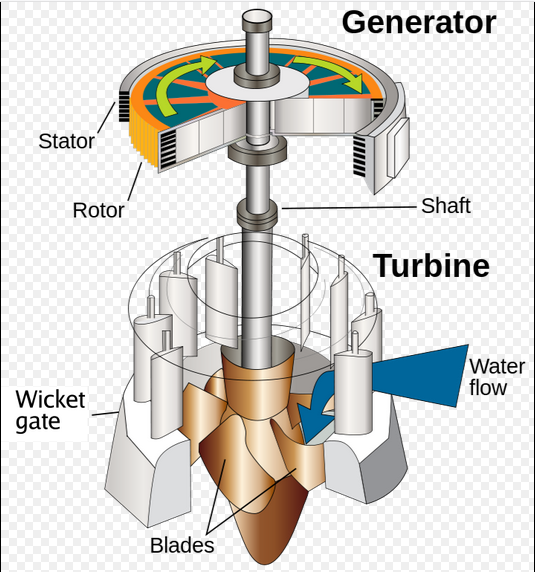

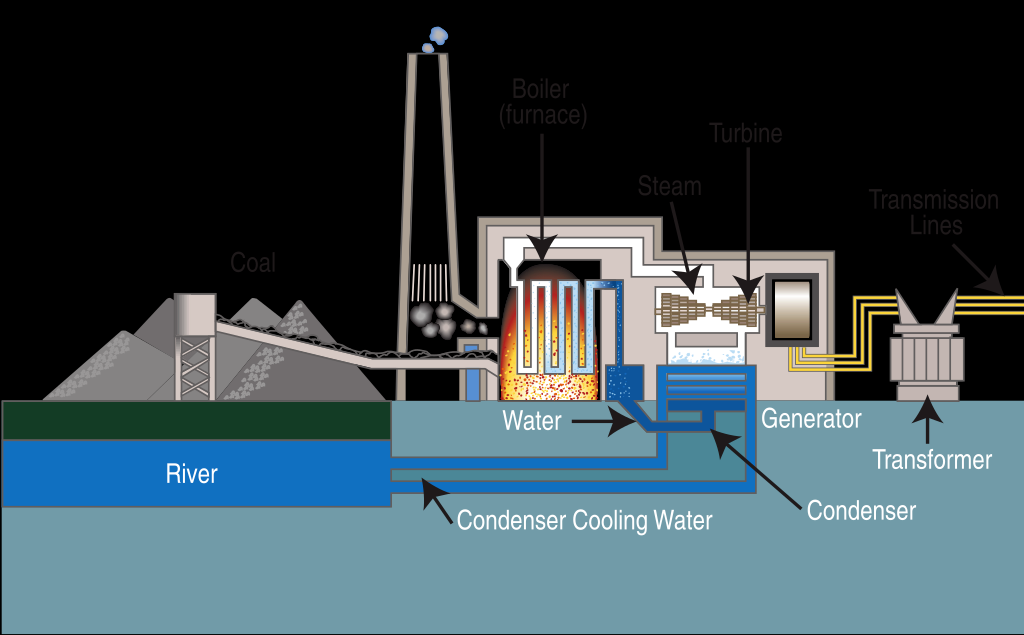

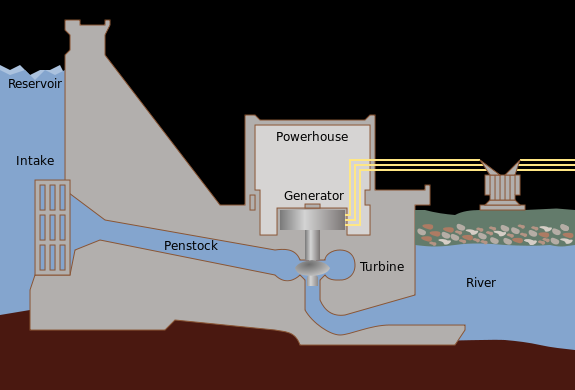

To help understand the control actions at the power plants, let us consider the boiler-turbine combination of a thermal generating unit. Most steam turbogenerators (and also hydroturbines) are equipped with turbine speed governors. The function of the speed governor is to monitor continuously the turbo-generator speed and to control the throttle valve which adjusts steam flow into the turbine (or the gate position in hydroturbines)

The parallel operation of generating units is facilitated by ensuring that the speed versus power output governing the characteristics of each unit must have a droop meaning that a decrease in speed should be accompanied by an increase in the load.

Unit Commitment

Owing to the fact that the total load on the power system varies throughout the day and reaches a different maximum value from one day to another, the electric utility has to estabish in advance which generators to start up and when to connect them to the network and the sequence in which the operating units should be shut down and for how long.

This procedure is often done by computer and is called unit commitment, and a unit, when scheduled for connection to the system, is said to be committed.

Unit commitment is different from economic dispatch in some respect in the sense that quite unlike on-line economic dispatch which economically distribute the actual system load as it arises to the various units already on-line, unit commitment plans for the best set of units to be available to supply predicted or forecast load of the system over a future time period.

Conclusion

Power generation at minimum cost has a direct relationship with operating efficiencies of generators, fuel cost and transmission losses. The most efficient generator in the system may not be the one operating at the least cost because it may be located in an area where fuel cost is high. Moreover, it may be located far away from the load centre which will entail long distance transmission to the load centres with the resultant high transmission losses and thus uneconomical.

Also there is need to identify the plants that will be operated for long hours based on the economics of fuel as against the plants that should be called upon during emergencies which do not necessarily have to operate at the least cost. Such plants must possess quick starting capability and ability to pick up load immediately and synchronise with other plants in the system.

References

- Effects of Variable Load on Power System

- Economic Dispatch and Unit Commitment

- Peak Load Plants and Base Load Plants

- Load Duration Curve

`

Being A SteemStem Member

Power generation just like any other business strives to operate at the least cost so as to improve on its profit. To achieve this economics, the power utility must forecast and prime generators that will pick up load as it comes up. The generator called up to pick up load must be suitable for the nature of load: Viz peak load and base load. Thanks for sharing.

Thanks for making out time to read the post.Your observation is in order.Peak load plant operates only to cater for peak load after which it is switched off. Base load plant operates continuously throughout the hours of the day due to its inherent low running cost.Thanks for your time and patience.

Economic operation of power system is essential in order to run a profitable venture without placing excessive burden of cost to the consumers. This is achieved mostly from choosing the right mix of generators based on efficiency, cost and proximity to consumers.Thanks for sharing

You nailed it again and I must say you have a good idea of what it takes to run an economic power system. Thanks for the time you invested in reading and commenting in my post. I appreciate.

I have never studied the economics of electric power distribution systems. I have always assumed the losses for distance from generation source to load were negligible. Have you learned of the percentage loss per distance from generation to load?

Very apt observation but you and I know that there are losses in the transmission line, though minimal. One cannot say it is negligible when you have to compare two or more power plants and the yardstick is the distance from generation to load centre.The plant closest to the load centre will have lesser losses, and also there are savings in transmission line structure making the economics of the plant that is closest to the load centre best when it comes to losses in transmission lines.