Let's talk about The Extrusion Process

Today is my birthday so I am super excited to be writing on this special day and It’s also a New month. Happy New Month Steemians, I wish everyone a fabulous month ahead.

Last month I visited my uncle and while we were having dinner one evening, my little inquisitive cousin kept bombarding me with questions which I enjoyed answering while we ate a delicious meal of macaroni and chicken. But then randomly she asked me a question I had no answer to, “Uncle D how do manufactures shape this macaroni we are eating to look like this.”

Honestly I would not Lie to you, I started stammering because I did not have a single clue on how to answer that question even though I really love to eat macaroni. But as a Smart uncle that I am I calmly responded by telling her to enjoy her food and promised to explain in details after dinner. Immediately I picked up my smartphone and checked google to get a detailed explanation for my smart niece.

Just like my little inquisitive cousin, have you ever wondered how they came about the shape of the macaroni you love so much? I know a few people would indicate that it is food processing, which is quite accurate but ultimately how they came about the shape is where the magic happens because macaroni are very smooth and do not have joints. But then they are not handmade, these types of shapes are derived in engineering using a process known as the extrusion process. This process is effectively utilized for metal forming and also in food processing to get great shapes for food like macaroni.

So Today I would be showing you how the extrusion process occurs.

A lot of times people erroneously associate the word extrusion solely to metal working process, which is not accurate. Personally I like to define extrusion as a defined process of creating a piece by the application of force. This piece could either be metal, plastic, ceramics or food. So in a nutshell extrusion process is utilized to efficiently create complex shapes on brittle items such as either food, metals, ceramics or even plastic.

The application of Extrusion process is vital to the production of the pipes we have in our homes; it is also an important part of food processing industries which efficiently utilize extrusion process for shaping cereals, snacks, and other edible items. It is also used for shaping the pellets of animal feeds. Aside manufacturing industries extrusion process is utilized to create drug carriers in pharmaceutical industries. Additionally, for renewable energy the application of Extrusion process is efficient in producing biomass briquettes which is used as fuel for various purposes.

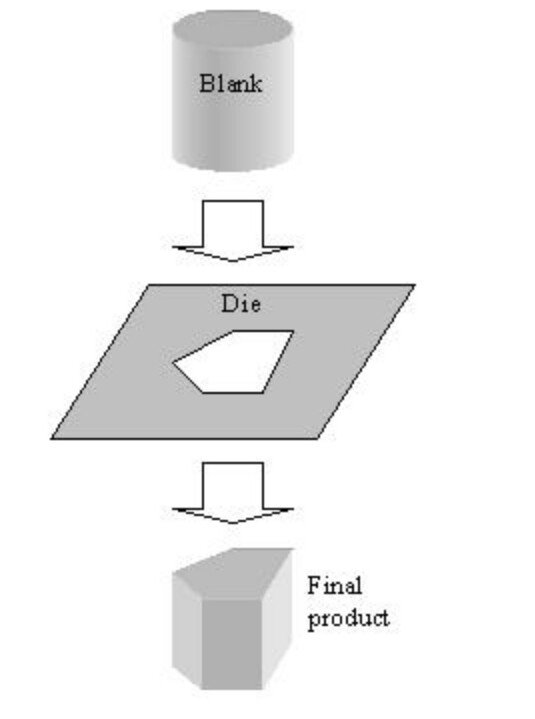

For extrusion to take place, there are two major things that are required which are the die and a powerful press. The die’s shape is ultimately responsible for the outcome of the extrusion process because the materials would be reshaped just like the die they pass through. The raw materials are forced through the die by a powerful press which is mostly in form of a hydraulics.

So for a manufacturer to create a trapezoid shape, he would need to utilize a die which would have a trapezoid shape cut inside the die for it to produce the required shape. Without the die this cannot be achieved. Extrusion process could happen several ways, in some cases the materials are applied directly while in some other cases processing must take place in the materials. Typically, extrusion process is of two major forms which are the hot extrusion process and the cold extrusion process.

Let’s take a look at these two processes

The hot extrusion process

To illustrate the hot extrusion process, I would like to use my little cousin’s macaroni, since it would be easier to understand and majority can relate to it. Let assume you want to reshape raw macaroni You would agree with me that if you take out raw macaroni from its sachet and you apply force on the macaroni to archive this, the raw macaroni would break and most likely you would not get the shape you desire.

But then if you cook that same macaroni and then you decide to make use of a knife to cut out a triangle. What do you think would happen this time around? Of course the desired shape can easily be derived from the cooked macaroni because in this state the macaroni can be manipulated to form anything unlike when it was in its raw form. The property of the macaroni is relatively different when it is cold.

In a nutshell for hot extrusion process to occur heating of the material has to occur. Heating is effective and necessary to reduce the hardness and strength of the material so the hot extrusion process can take place. The materials are mostly heated to temperatures above their recrystallization temperature, this temperature ensures the materials are not solid or liquid. Once this is achieved the heated materials are forced through a suitable die by applying force on the hydraulic press, as they pass through the die the materials would reshaped to be similar to the die. Then finally the materials are allowed to cool down and the unique shape required is created.

The cold extrusion process

Typically, this type of extrusion happens below the material’s crystallization temperature, mostly at room temperature. This cold extrusion process is very effective for materials that are ductile and soft because it utilizes pressure to carry out this process. Compared with the hot extrusion process, the cold extrusion requires more pressure to be effective.

One advantage of this type of extrusion is that the materials do not require Heating which would ensure that the materials produced have better strength and surface areas. Cold extrusion process is suitable for lead, aluminum, and tin amongst several others.

CONCLUSION

The application of Extrusion process is vital to various fields and not restricted to just engineering. It is efficient for not just metals but can also be used for ceramics, plastics and also for food processing to produce required shapes. Extrusion process combines the use of a die which determines the shape of the materials and force in hydraulic power to shape materials for various purposes.

In some cases, the materials are heated before the hydraulic press is used to force the heated materials through the die, while in some other cases the hydraulic press in applied directly on the materials at room temperature. Each method is useful and effective for different materials. I hope you gained something from this article.

Wish me a Happy birthday and drop your comments below.

REFERENCES

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

You can also join us at Promo-Mentors, to improve your blogging skills. Join our discord channel and meet awesome mentors who are willing and ready to shape your writing skills.

Congratulations @happydaniel! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Vote for @Steemitboard as a witness to get one more award and increased upvotes!