MATERIAL HANDLING IN AGRICULTURE : The Unsung Hero of Agricultural production.

There is an adage in my native language, that when loosely translated, will mean "When a boy kills a small fish, he eats it alone, when he kills a rat, he eats it alone, but when he kills a whale (not a steemit whale 😁), he calls his parents for help". Funny isn't it? but very true. The proverb isn't focusing on the child's apparent selfishness but on the fact that he has realised he has more than his little hands can handle, so he seeks help from "higher powers".

This proverb closely related to what happens with humans and agriculture. Either when practicing subsistence agriculture or small scale farming, it is hardly a problem to move and store agricultural products, so a farmer in both cases may not need any help in dealing with his produce. However, what happens in large scale farming, when he has to deal with a large quantity of materials, either after harvest, during storage or when the time comes for harvesting, his matter then becomes like that little boy that needs the help of a higher power, albeit in his own case, just human help won't be enough.

So what higher power comes to the rescue in such cases where large agricultural products need tonne moved or transported from one point to the other? Please allow me to introduce you to the mostly unheralded saviours - Material Handling Systems. If you read my post on Silos, I promised to explain how such large amount of agricultural products stored in the Silo are moved to and from it.

Well, now is the time, as today I'll be discussing what Material Handling is in agriculture and the major Material Handling methods that come to the rescue in agriculture, and with that I say welcome here once again, it's always a pleasure to have you here. So without dilly-dallying, let's get the products moving.

You may notice that I've specified the type of Material Handling we're here to discuss, that is because Material Handling is a very broad field, that finds application in different fields, but with the same basic principles, and we will be focusing on its application in Agriculture.

Material Handling is used to describe all the processes involved in the movement of agricultural products, either in their raw form, during processing and in their processed forms.

According to Coyle (1992), this movement is usually over a short distance. This movement can be in the form of loading, unloading, packing, distribution and so on.

Let us take the grains store in Silos for example. The grains will have to be moved from the field after the harvest, in fact, material handling starts right from the point of harvest as you will see later. These grains will have to be transported to where they will be cleaned and processed before making sure that they get to the Silo. Now, you may remember that Silos can be tall, so it is these Material Handling equipment that still ensure the proper and sage transfer of the products into storage structures like Silos. What happens when you need to take the grains out if the Silo, you guessed it, the equipment to the rescue again. This really underscores how material handling pervades post harvest processes in agriculture.

Like almost all the processes we have today, you can have material handling at different levels of sophistication. I'll briefly discuss those below :

Manual Material Handling : Actually, I don't like being the guy that states the obvious, but it appears in this case, I don't have a choice. This category is for those processes that are carried out using human hands as the means of movement, be it for lifting, packing, loading or any of the processes earlier mentioned. It also goes without saying that this method of handling materials poses a lot of risks to workers in the production line, as most of the carrying and lifting is done with the back, and it is the reason why a lot of ergonomic improvements like hoists and lift tables have been made to ease the amount of danger that manual handling causes.

It is for this main reason, that we have the other methods of handling materials, so that we don't get "handled" while trying to handle materials.

Semi-automated Material Handling :When a farm tries to eliminate as much danger to their workers as possible but still cannot afford to run total automation of their Material handling, this is what they go for. Here, a particular process of handling is mainly handles by a machine but is operated by a human, for example a driver or an operator. This is the method of handling usually found on many farms. This is sometimes confused for another material handling method that will be discussed last, watch out for the significant difference.

Automated Material Handling : I could have referred to this as the fully automated method, but I suppose that will be tautology. In this type of material handling, highly sophisticated technologies are employed to replace any manual handling, such that all processes are handled by machines. You know those guys called robots, yes those guys are the main boys behind this material handling methods. There are already farms that start the use of robots from the point of harvesting.

This method also comes in handy when the materials to be handled require the highest hygiene level and zero tolerance for contamination. An example that comes to my mind is that of some dairy farms in Israel that have their system so automated that animals do not need to be told when to go for milking.

These animals are said to have sensors (My professor has visited the farm in the past and told me so, just so you know I haven't visited the farm myself. I don't mind a sponsor though) that can tell when the volume is ripe for milking and the animal is triggered to move to the milking stand where a machine does the milking, such that from start to finish, there is no need for human interference.

- Integrated Material Handling : As I mentioned earlier, this method is usually confused with Semi-automated handling. So let's use this scenario to make the difference clear. Let's say you're a transporter that moves Celebs between two cities, but most of the time you only drive them halfway the journey yourself before making them alight and be ushered by some beautiful ladies on red carpet into a driver less car that you own and have programmed to travel from that point to the other city that completes their journey.

You can compare the first process of driving the car yourself to the Semi-automated handling, while the female ushers carried out the manual handling, then the driver less car plays the part of automated handling. Now, your whole company will be referred to as an Integrated transporting company. Need I say more? The integrated handling combines one or more of the three previously mentioned handling methods, so before you can say it is integrated, at least two methods must be present.

Agricultural Material Handling Equipment

Now, let me briefly acquaint you with some three divisions of Material Handling equipment that are mainly used in Agriculture. Note that they are not restricted to what I'll be mentioning, but these are the main ones you'll find on most farms. Let's focus on Conveyors, Elevators and Cranes/Trucks.

- CONVEYORS : I don't know if I should tell you that the

worst kept secret in the material handling worldis that conveyors convey substances (you didn't hear that from me).Well, i ask my beloved Merriam Webster Dictionary and it says they are mechanical tools used for moving bulk materials from one place to another. Now let's discuss three types of conveyors :

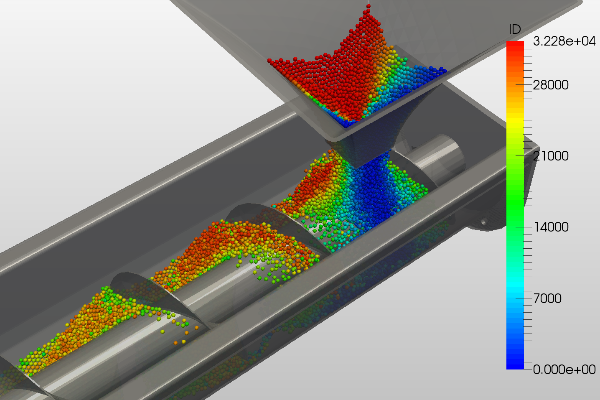

Screw Conveyors : If you chose to call it an Auger Conveyor, you're still very correct. These basically move materials by employing the principle of rotation. A typical one has a helical screw that is usually mounted on a shaft. This shaft when driven by electric motors or tractors (through power transmission shafts) moves materials ranging from cereals to animal feed at a rate that is proportional to the speed of rotation and the angle of inclination in inclined types.

These screws are either horizontal or inclined, and in case you're about to say that you have never seen these screws, a good reason is because they are usually enclosed in tubes or troughs. But if you've seen how a combined harvester transfers harvested grains to trucks, then you've seen one at work. If not, this picture should do for now.Belt Conveyors : These conveyors are also built on the principle of rotation albeit they do so it a arrangement of a belt and two pulleys; a powered pulley (connected to the power source) and the idler pulley. The belts are mounted on these pulleys, and the materials to be moved are placed on the belts, such that as the pulleys rotate the belts, the materials are transported. These materials range from fruits to grains and even boxes of packaged products.

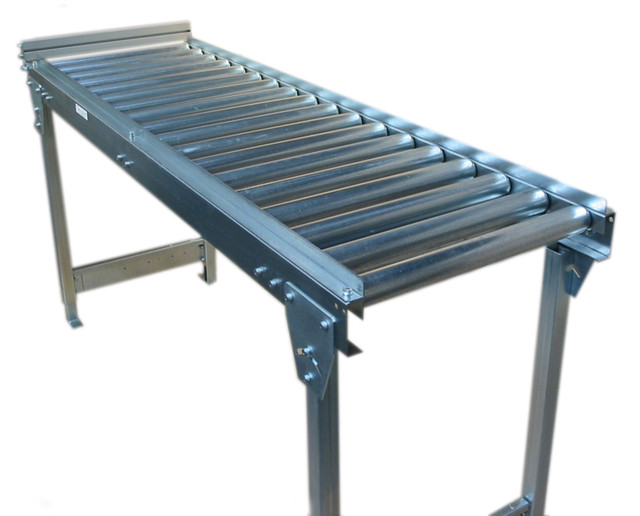

Roller Conveyors : These conveyors are used for carrying bulk materials that are larger as those carried by the previous conveyors. They employ rollers that are driven by a major shaft. The shaft and rollers are connected by spots. Usually, the shafts are driven by electric motors. The fact that the rollers are connected to the shafts by spools are said to have a safety benefit, for slip and for trappings in the system.

BUCKET ELEVATORS : This is the type of elevators mainly used in agriculture. Usually an arrangement of buckets and belts, or sometimes chains. The bucket scoops the material from a pile at a lower level and holds it parallel to the floor until it reaches a higher point where it deposits the material by tipping the bucket. There are three major types : Centrifugal Discharge Elevators- mainly used for grains in grain elevators. Continuous Discharge Elevators and Positive Discharge Elevators which are used to convey completely processed food materials like popcorn.

- CRANES/TRUCKS : These two are together because they usually work side by side in Agricultural Material handling. Cranes are usually used for unloading packed raw materials or products from trucks, for stacking them for storage before or after processing in warehouses and for loading packed final products into trucks.

The good thing about most parents is that as much as they possibly can, they try to help their children to the best of their ability. Well, two problems exist in this case, first their best may not be enough, and secondly because we don't get to choose our parents, some of us may feel hard done by.

However, with a good knowledge of Material Handling, both of these can be avoided when there is need for a higher power to help in handling agricultural materials. As to whether one is better served by sticking to the manual methods, spicing things up with partial automation, going fully automated or ultimately combining them all, a good choice will always give the best results.

It is worthy of note that these methods and equipment of material handling survive on a backbone of Material Handling principles like the Unit load principle which focuses on assembling materials together into one large unit as much as possible, which is what equipment like Roller Conveyors and Cranes thrive upon.

Also, the Layout principle encourages sequential movement based on the sequence of harvest to production processes. There is also the Ergonomic principle which is concerned about reducing as much discomfort as possible for the humans in the movement process. There are just some of the principles.

It is believed that Robots are the future of Material Handling in agriculture, but due to the cost and technicalities involved, their usage is not yet widespread, but before that time and beyond then, the methods and equipment mentioned are always ready to serve us well if we are ready to use them rightly.

I hope I have been able to convey a truckload of elevated knowledge into your knowledge bank about how agricultural materials go by their everyday journey. Thank you.

REFERENCES

Coyle, J.J. (1992). Management of Business Logistics. Mason, OH: South-Western. p. 308.

Ergonomic Guidelines for Manual Material Handling" (PDF). California Department of Industrial Relations. 2007

MATERIAL HANDLING | INTEGRATED MATERIAL HANDLING SYSTEMS | MATERIAL HANDLING - PRINCIPLES, OPERATIONS AND EQUIPMENT | CONVEYOR BELT | CONVEYOR SYSTEM | BUCKET ELEVATOR

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

Material handling systems affords us the chance of moving goods to places without fear of goods being compromised by human factor.

This is a very important topic you have discussed here.

All we have to do is try our best to harness them well. I'm happy you find it important.

Hello! I find your post valuable for the wafrica community! Thanks for the great post! @wafrica is now following you! ALWAYs follow @wafrica and use the wafrica tag!

A very good one here on agriculture. You must be a very good Agriculture and bio-resources Engineer. I enjoyed your post on silos as well. Kudos!

Thanks for your encouraging comment.

Production engineering. 500l MCE

you just brought back memories.

Material handling is very important aspect of production. If not done right, we might as well be eating our products on the farm

Truly, without material handling, we might as well forget about processing and storage, which of course means sure wastage of everything left after we've filled our small stomachs. Thanks for always being here.

Gbayi!

Material handling is an integral part of production engineering. It must be planned while considering the preferred Plant layout and the process layout so as to place material handling equipment at the optimal location for workers and the goods to be moved

This is a nice topic you spoke about and as usual, you did justice...Well done and thanks for refreshing my memories..

I love the adage part..Cheers

Very good point there, the Layout principle as I pointed out in the conclusion is one of many principles that must be considered to ensure that the whole process is effective.

I'm always happy to see you read my blog and drop meaningful comments.

It's a pleasure always...Your quality post attracts me

Noted

I did pick up a few point as a farmer.

I'm glad I could add something.

We are related after all... Our lives are made easier because of your existence.

#life of a farmer

Material handling is a great part of agriculture and i like the way you dissected it.. Also that farm you talked about.. Please we can visit it together 😂

I'm looking for sponsors o, maybe you're the one I've been waiting for

Material Handling is one backbone of any producing sector. It comes in different forms as you have noted. Agriculture is another backbone of life and really needs a lot of technological aids. You have done well, as usual, to serve us with this informative and well-crafted article.

Kudos!