LET'S TALK ABOUT MATERIALS! SECOND PART

Greetings to the entire community of steemit and steemstem, this time I will continue talking about materials, specifically solids, especially those used in mechanical technology, I hope you find the information provided useful.

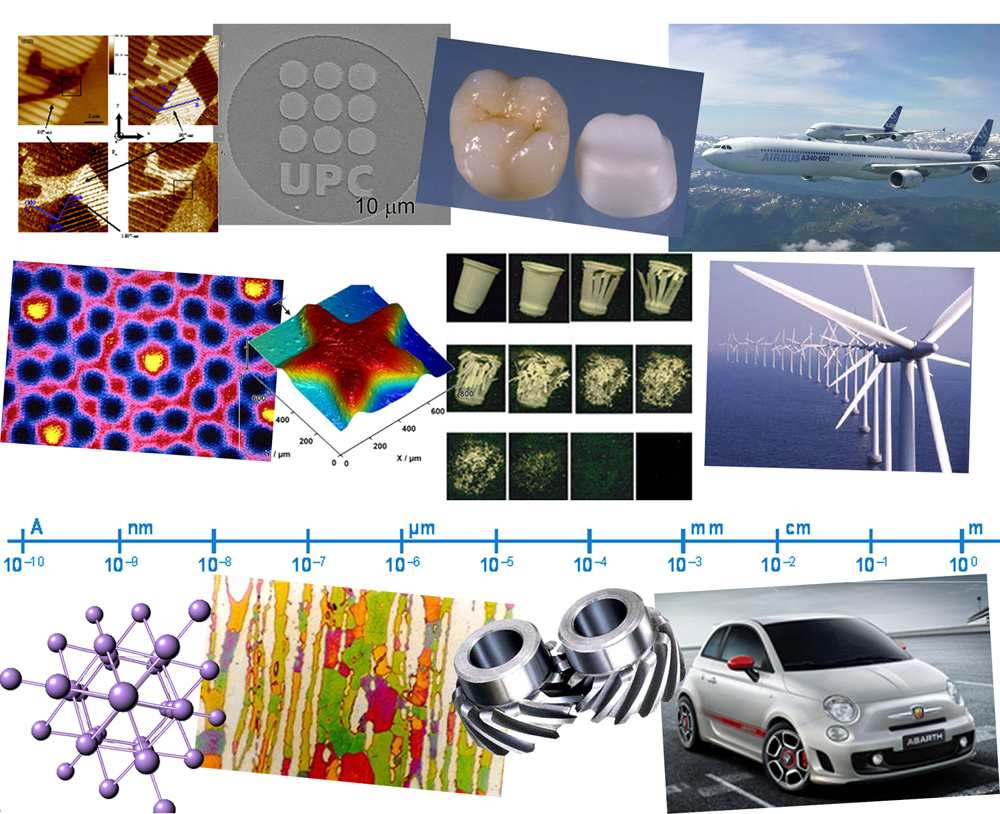

Source

CLASSIFICATION OF MATERIALS

Solid materials are usually grouped into three basic families: metals, polymers and ceramics. The first two are the ones that are most used in mechanical technology, while ceramics are the basic materials of other diverse activities.

The atoms of the metallic materials form a characteristic crystalline network in which the electrons have a great mobility, which gives them a good conduction of electricity and heat. Other outstanding properties of the metals are: relatively high density, good mechanical resistance and rigidity, as well as the possibility of plastic shaping.

Polymers are materials formed by long molecules of organic material, resulting from the chain of smaller chemical units to which various types of substances are added to modify some of their characteristics.

Its most outstanding properties are its low density, its moderate mechanical strength and rigidity and its insulation from electricity and heat.

Ceramic materials are chemical compounds of a metal and a non-metal, and their molecules can present a great diversity of crystalline structures without free electrons. Its most outstanding properties are its relatively low density, good mechanical resistance and very high stiffness, but great fragility, very low heat and electricity conduction and high chemical stability.

FERROUS MATERIALS

Iron is a very widespread material in nature, whose process of obtaining it has a lower energy cost than that of other alternative materials. Pure iron is a very soft material that has few applications. The ferrous materials that we normally use contain, to a greater or lesser degree, carbon, as a result of their production process, which gives them much better properties.

Ferrous materials are a simple, effective and cheap solution in many applications for machines and other appliances, so their use is the most widespread among all metallic materials.

NON-FERROUS METAL MATERIALS

Although ferrous materials are the most important in mechanical technology, other metallurgies have been developed that have occupied important plots in the manufacture of machines and appliances.

Among the non-ferrous materials include aluminum alloys, which, thanks to its lightness and resistance to corrosion, have taken over in many applications in which these properties are decisive.

Copper alloys have followed an almost inverse process: to be the predecessor of ferrous materials, they have been giving way to other materials, largely due to their high density and cost.

Finally, other metallic materials, especially the alloys of magnesium, zinc, nickel and titanium, find specific applications that have originated an own market, although limited.

POLYMERS

Plastics are rigid consistency polymers when compared to elastomers. Plastics find multiple applications thanks to their interesting properties, such as their low density, heat and electricity insulating, their comformation ease and their economic price.

ELASTOMERS

Elastomers are polymer-based materials with elastic behavior, flexible consistency and high tenacity.

After the use of natural rubber, parallel to the use of the automobile, in 1950 barely half a dozen elastomers were known, while at present there are more than 30 families with properties suitable for various specialized elements of the machines such as gaskets, seals, protections, elastic joints and suspension elements.

Natural rubber and other equivalent synthetic rubbers used mainly in the manufacture of tires, have excellent mechanical properties, but low resistance to atmospheric agents and oils and their temperatures of use are moderate.

Other elastomers resist the atmospheric agents and higher temperatures well, but they behave badly against the oils, among them the butyl rubbers stand out, very impermeable to gases, as well as the ethylene-propylene rubbers, which is very resistant to chemical attack.

Among the oil-resistant elastomers include polychloroprene, also called neoprene, of good mechanical strength and nitrile rubbers, more resistant to oils than the previous, have the best mechanical strength of all elastomers, but with a temperature of use very moderate.

References:

Enciclopedia de la Ciencia y la Tecnología, Ediciones DANAE.

For more information you can visit the following pages: