Basic guide for oil fractionation or distillation - (Part 1)

What is Fractionation?

Synonym of rectification and is commonly applied to the rectification operations of the oil industry.

source

What is the rectification?

It is a distillation carried out in such a way that the steam obtained in the tower is brought into contact with a condensed fraction of the steam previously produced in the same apparatus. This contact results in a transfer of material and an exchange of heat, thus achieving a greater enrichment of the steam in the more volatile elements that could be achieved with a simple distillation operation that uses the same amount of heat. The condensed vapors that are returned to achieve this goal are called reflux.

source

What is the reflux?

Condensed vapors that are returned to the fractionation tower to enrich the top producer with the most volatile elements.

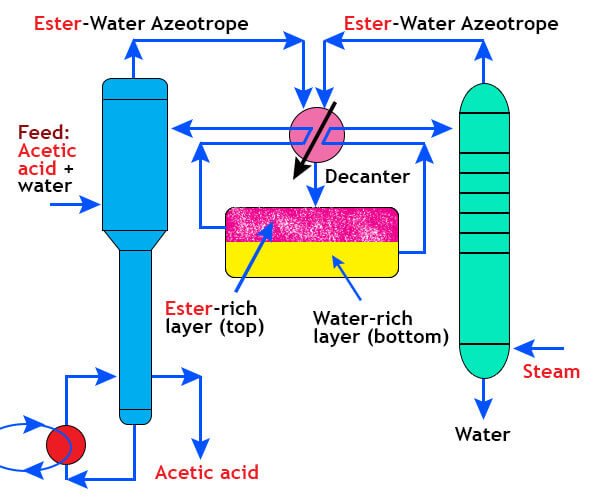

Azeotropic distillation

Distillation in which the existence of an azeotrope facilitates the separation of a component of a mixture. If the azeotrope in question is not present in the system, it can be formed by introducing to the mixture to separate an element that allows its formation. The separation will be facilitated as a function of the variation between the boiling point of the azeotrope and the components of the mixture.

source

The distillation process can be carried out in different types of columns that can be classified, in relation to their internal devices in:

columns of dishes

fill columns

Depending on the mode of operation, the following types of distillation can be found:

Distillation by loads (or discontinuous): the mixture to be distilled is introduced directly into the kettle and the steam passes to a fractionating column. It is used to recover volatile components of a mixture and when the amount to be treated is small.

Continuous distillation: the feed is continuously introduced to the column. It is the most common way to operate.

According to the number of components that contain the incoming mixture to the column, the following are distinguished:

Binary distillation: the incoming mixture to the column consists of only two compounds.

Multi-component distillation: the separation of a mixture composed of more than two chemical substances is carried out.

I hope you enjoyed my first basic explanation of what I do.

If you have any comments, do not forget to leave it.

Thank you so much.