**Preventive maintenance of a driver or high frequency cornet.**

Preventive maintenance of a driver or high frequency cornet.

The driver that I chose to maintain was the Eminence psd-3006, whose features are:

• 2-inch titanium diaphragm.

• It has a ceramic magnet.

• 100W AES power capacity.

• Nominal impedance 8 ohm.

• Frequency response (800hz-20000 kHz).

• Eminence manufactured in the USA.

** Tools to be used: ** Allen wrench, 10mm wrench, spline screwdriver.

Steps to follow:

** First step: ** The diffuser is separated from the driver by loosening the screws with the 10 millimeter wrench.

** Second step: ** The diffuser is wiped clean to remove dust or dirt.

** Third step: ** Proceed to disassemble the driver to remove the membrane from it.

** Fourth step: ** With a sheet of machine proceeds to clean the driver inside the channel where the membrane is placed in order to remove accumulated dirt and dust, since a dirty driver carries bad sound, or can even damaged because it causes friction between the membrane and the wall of the magnet.

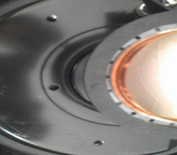

** Fifth step: ** Proceed to arm the driver again, if we see in the photo of the magnet has a hole which is the guide where the membrane goes, and is not misaligned with it.

** Sixth step: ** the screws are placed and they are adjusted with a pulse tightening that is not so strong and cross-shaped.

** Seventh step: ** Proceed to arm the driver with the diffuser.

** Eighth step: ** We proceed to test this driver to see how it works, the positive cable is placed with the red connector of the driver, then the negative cable with the black connector, a music is placed and there is a video Short of how the driver is sounding.

Thank you for reading my post and for your votes.