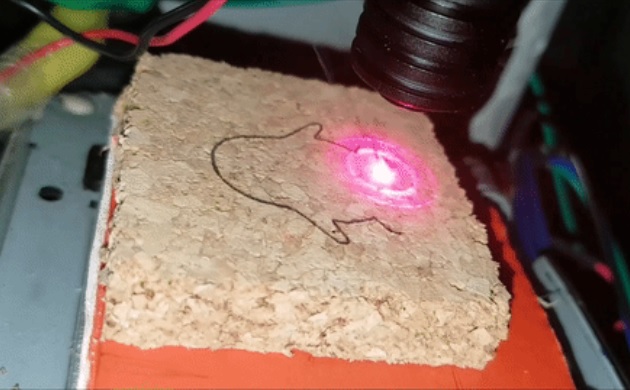

DIY Laser Engraver made from old DVD drives! Engraves on wood, cork and more!

Recently, I participated in Maker Faire Singapore 2017 showcasing this laser engraver that I worked on with 4 of my friends! It is made based on the red laser diode, precision stepper motor and gears all found in 2 DVD drives. Together with an arduino, an open-source software known as GRBL and GRBL-controller, we made this over around 7 days.

(The GIF is sped up to around 16x)

Below are some of the things we engraved. We gave out quite a few of these to interested visitors to the fair! These were the few that were left. It takes 10-20 minutes to burn one of these.

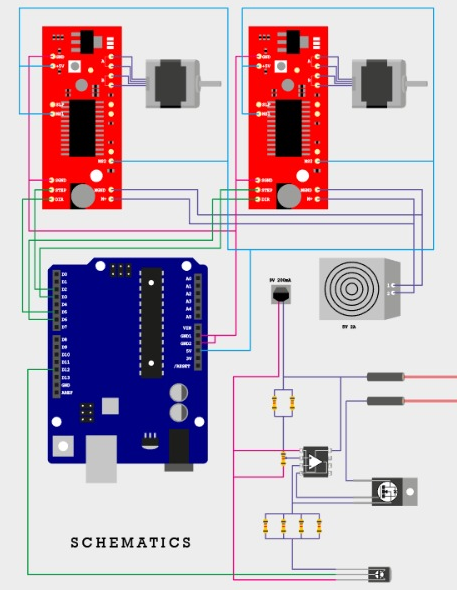

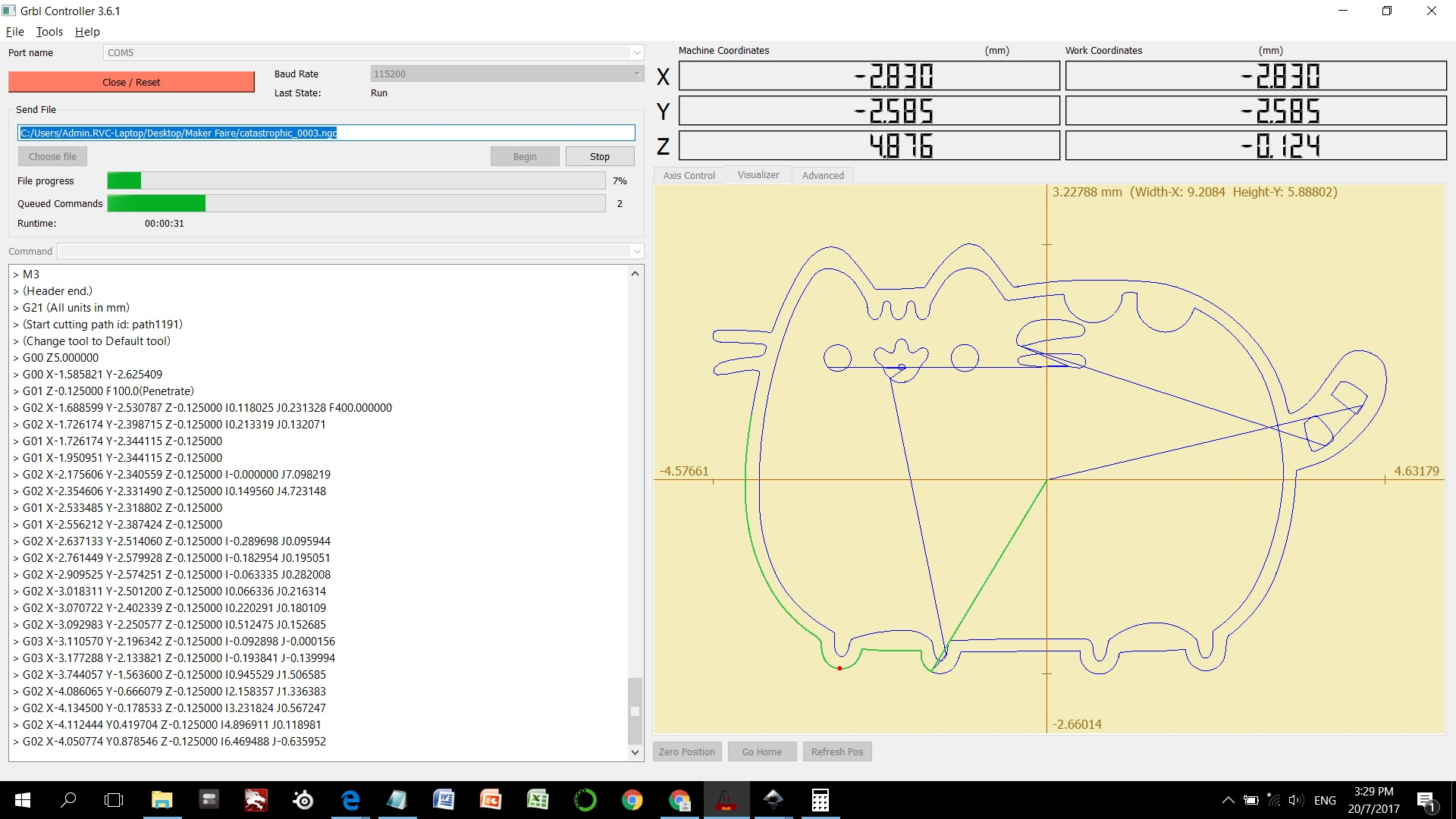

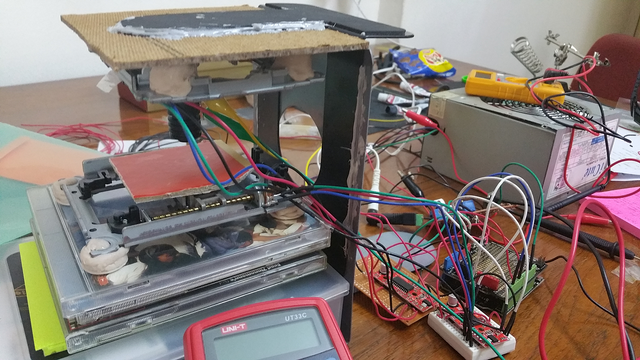

The laser engraver consists of the stepper motor frames, that convert the precision rotational motion of the stepper motors into a precision translational motion. The base holds the piece of cork and moves in the x-axis, while the ceiling holds the laser housing and moves in the y-axis. A stepper motor driver - the EasyDriver - sends times pulses to control the positions. The stepper motor is in turn controlled by the Arduino with GRBL loaded on it. GRBL is a software that parses G-code and converts it into well-timed movements so that the steppers move to the correct position for the correct amount of time. Finally, the computer is connected via USB to the Arduino and the GRBL-controller software send serial input into the Arduino.

Below is a screenshot of the GUI interface of GRBL-controller.

The laser diode is run by a constant current circuit, and the light is focused by a small lens embedded in the laser housing. This is the setup before we neatened it:

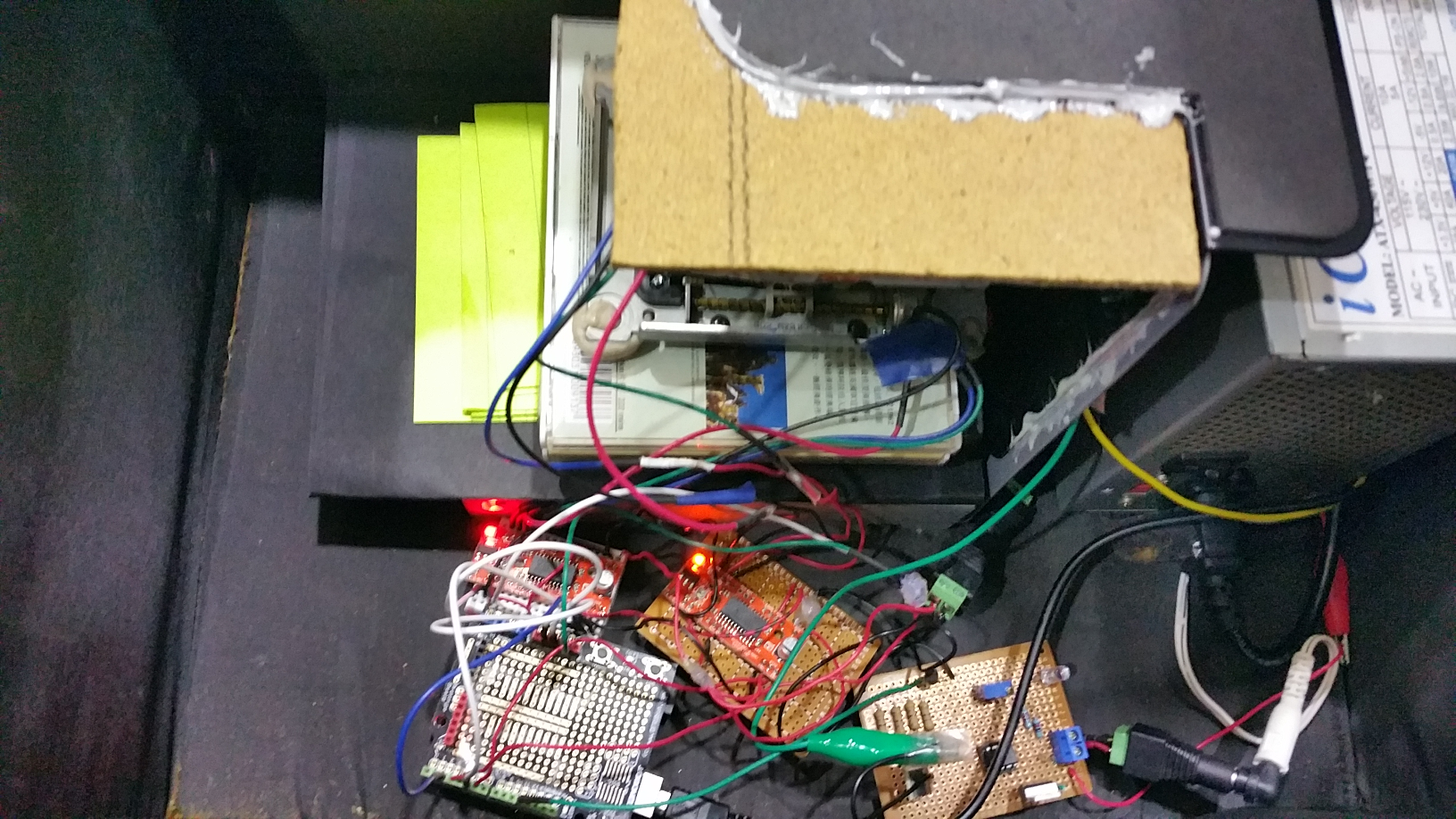

And after we neatened it and placed it all into a box:

Here are the open source software we used:

http://zapmaker.org/projects/grbl-controller-3-0/

Thanks! Feel free to ask any questions about it!

Wow, that is really cool. Is the 20 min time because the laser takes that long to heat the cork up? If so, could the burn time be reduced by using the laser out of a blu-ray player?

It's due to the fact that the laser takes a while to burn a spot on the cork, so the laser has to move slow enough such that the cork burns up. I think using a blu-ray laser would indeed reduce burn time

yes i made a post about laser engravers and how CHEAP they are like $30 now! its just a laser and a printr basically!

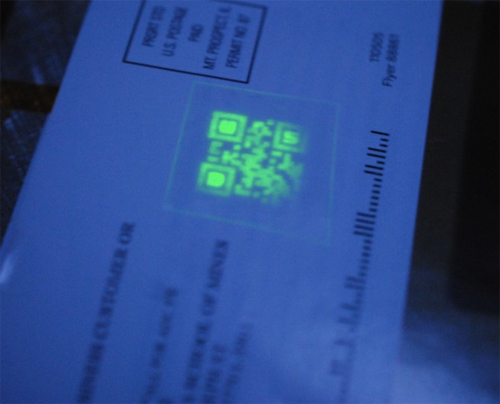

You can use it to engrave a QR code of your steemit walet master key onto a quartz crystal or make a TINY qr code etched microscopically ontoa plate of glass or in your contact lens

I know the cheapest one hre is $99 but I found a bunch iof $30 and $30 ones they are supr cheap and why wouldnt they be its just a printer with a laser instead of ink lol

And then laser Engrave the QR code of your steemit password key or bitcoin wallet key onto a Quartz Crystal and it would be so sci fi ...the crystal could be worth so much money!

or make it invisible

Cool to know!

I didn't think those little lasers had it in them to output enough power for burning anything other than the dye layer of a CD/DVD R. Well done!

I love the ingenuity and resourcefulness employed by those who would rather see useful things reused and repurposed rather than just sent off to be more toxic landfill. Good on your for also taking time to provide a schematic and links to the resources used, open source FTW. You deserve the steem/SBD rewards, hopefully you get plenty to fund further projects, at least.

You also deserve a trophy, so here you go:

Thank you! The rewards here definitely motivate me and help me to work on more similar projects!

Excellent post, I have been meaning to do something like this for a while, I have the old DVD laying around collecting dust but no motivation to start. I'll follow you and see what happens with your builds.

I laser engrave on metals a lot and we have to outsource. If this could engrave steel at a depth of 20 micron Id do it. Are there any changes that could increase the power of the beam?

well done very creative :)

You are a genius !! I am following you to see more.

Good job!

Thanks!

Looks perfect and very precise, is a very good creation and very useful, excellent friend congratulations I hope you can with the passing of the days things better and high quality. I follow you, success.

thanks for the info, i didnt think of this myself, now im wiser :)