A Guide to Radius Gauges: Uses, Types, and Importance

A Guide to Radius Gauges: Uses, Types, and Importance

Introduction

A radius gauge, also known as a fillet gauge, is a tool used to measure the curvature or radius of an object. These gauges are essential in machining, manufacturing, and quality control, ensuring parts meet specific design requirements.

- What is a Radius Gauge?

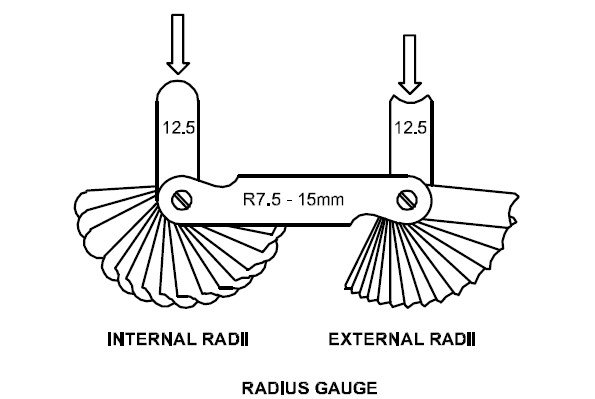

A radius gauge consists of a set of metal or plastic blades, each representing a different radius. These blades allow you to quickly compare the curvature of a surface against the standard radius indicated on the gauge.

- Types of Radius Gauges

There are a few types of radius gauges available:

• Internal Radius Gauge: Measures the radius of concave surfaces (inward curves).

• External Radius Gauge: Measures the radius of convex surfaces (outward curves).

• Adjustable Radius Gauge: Some gauges allow adjustment for more versatile measuring.

Applications of Radius Gauges

• Machining and Fabrication: Used to check the accuracy of part radii in production.

• Tool and Die Making: Ensures precise fillets and corners on molds.

• Quality Control: Verifies that manufactured parts match design specifications.Proper Use and Care

Using a radius gauge is simple: match the blade with the part’s curve, and ensure a perfect fit. Always clean the gauge after use and store it in a protective case to prevent damage and ensure long-lasting accuracy.

Conclusion

Radius gauges are indispensable in industries where precise curvature is critical. From checking part dimensions to ensuring smooth transitions in design, these tools are vital for achieving high-quality, accurate results.

Do you use radius gauges in your projects? Share your experiences below! 💬

#RadiusGauge #PrecisionTools #Machining #QualityControl #Tooling