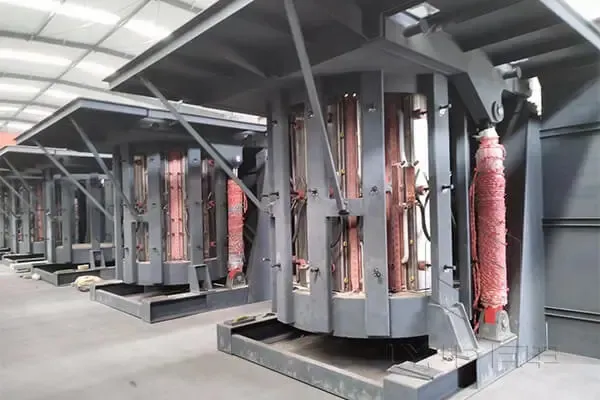

Production furnace

Judian steel smelting furnace

The determination of the point at which the temperature rises the slowest is mostly a matter of guesswork. Placing the pyrometer at this point is easy for some shapes of workpieces. For workpieces of ordinary shapes, the instrument is likely to be damaged during loading and unloading. When heating large parts, this slowest point is located inside the object and cannot be reached.

Production furnace

It is more convenient to measure and control the temperature of the furnace rather than the temperature of the material. The temperature of the furnace is expressed by the temperature of the inner wall of the protective tube of the measuring device.

This tube is closed and protrudes a short distance above the furnace roof or side wall. The tube is radiated by the furnace roof and walls, as well as by the resistors, the radiation tubes and the furnace gases. The outer shell of the tube radiates heat to the charge. While the charge is being heated, the furnace temperature is some indefinite "intermediate" temperature. Towards the end of the heating process, the outer surface of the charge reaches a temperature close to that of the furnace roof, walls and gases. The process is shown in Figure 105.

The location of the pyrometer is important. It is best to place it near the point on the charge that first reaches the final temperature. It must not be placed in the burning fuel stream, nor near the heating elements, nor near the furnace door that is often opened.

When the temperature curve becomes horizontal, it indicates that the outer surface of the charge has reached the required temperature, but, as pointed out above, it does not indicate the temperature of the slowest point.

If no pyrometer is placed at that point, the following method is often used: a test run is carried out with normal charge, and the pyrometer at the "slow point" will indicate the time lag (the time difference between the furnace temperature curve flattening and the end of the "slow point" heating), and this data can be used for the same or similar charges.

The test run may involve drilling a hole in the charge to allow the insertion of a pyrometer. For unusual charges, the calculations given in the previous volume will be helpful in using the test run data. In furnaces where the charge is continuously passed through the furnace, the temperature is controlled so that the outer surface of the charge is brought to a given temperature at the hot end of the furnace. The uniformity of the temperature within the heated charge depends on the time it is in the furnace. The same applies to furnaces that are always fully loaded (a block of charge is taken out and another is immediately put in). The number of control points and the ease of control when using various fuels will be discussed at the end of this chapter.<