Geothermal Power Plant, Enhanced Geothermal System

Enhanced Geothermal System (EGS) is a geothermal power plant without the need for convective hydrothermal natural resources.

To date, geothermal power systems have been utilized solely on the basis of natural resources where heat, water, and rock permeability are sufficient to allow for energy extraction.

However, so far most of the geothermal energy in the range of conventional techniques is in dry and impermeable stones.

EGS technology enhances and / or creates geothermal resources in hot dry rock (HDR-hot dry rock) through 'hydraulic stimulation' or fluid stimulation.

This EGS technology utilizes cracks in rocks to create heat and generate more efficient and effective geothermal energy.

When natural cracks and pores can not keep up with the rate of economic growth, permeability can be increased by pumping high-pressure cold water into the injection well into the rock.

Injection will increase fluid pressure in natural fracturing rocks, mobilize shear events that increase the permeability of the system.

Because there is a continuous circulation, it does not require high permeability, nor hydraulic fracturing proppants necessary to maintain an open fault.

This process is called hydro-shearing, perhaps to distinguish it from the hydraulic tensile fracturing used in the oil and gas industry, which explodes through the stone rather than relying only on the natural fracture.

The water moves through the fracture in the rock, capturing the rock's heat until it is forced out of the second drill hole as very hot water.

The hot water is converted into electricity using either a steam turbine or a binary power system. All water is cooled, injected back into the soil to be reheated again in a closed loop.

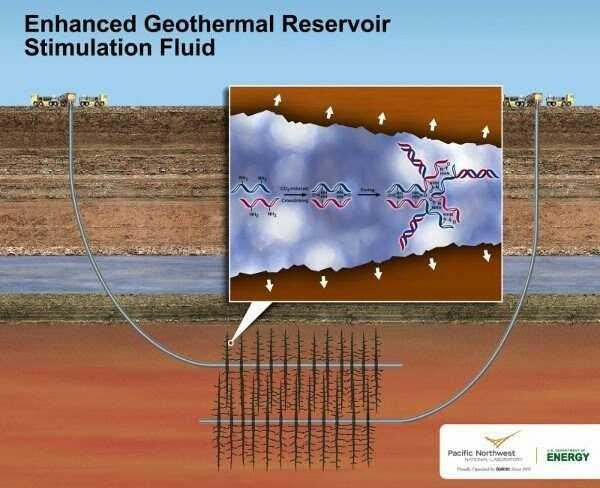

Pacific Northwest National Laboratory produces geothermal power that is more environmentally friendly and cheaper than other conventional geothermal plants.

Stimulation of his geothermal fluid is able to support more homes.

Pacific Northwest National Laboratory develops non-toxic and environmentally friendly liquids, designed for use in enhancing geothermal systems, where fluids are injected into boreholes leading to an underground geothermal reservoir.

The fluid expands when exposed to underground carbon dioxide, which creates a small crack and deep behind the rockyness.

The new liquid reservoir stimulation is equipped with environmentally friendly polymers that can expand the volume of fluid, which creates tiny cracks in underground rocks to increase electricity production.

This fluid can also substantially reduce the water footprint and cost of the geothermal enhancement system.

A paper describing the fluid has been published by the Royal Society of Chemistry in the online version of the journal Green Chemistry.

This new fluid can make electricity production in EGS more feasible.

Although initially the liquid is designed for geothermal energy, it can also be explored in the non-conventional oil and gas industry for more environmentally friendly protection.

EGS is able to suppress excess fluid usage where only half of the water in the use of other conventional geothermal generators is used.

Of course this is able to reduce operating costs are cheaper and more environmentally friendly.

Fluids may be an advantage in this new approach to geothermal power generation today.

#EGS Geothermal Power

Conventional geothermal power plants depend on the natural existence of three things: underground water, porous rocks and heat.

The geothermal power generated is obtained by suppressing the heat beneath the earth's surface to extract the steam and turn the power plant turbine.

Increased geothermal power can be generated in locations where heat exists, but not easily accessible due to insufficient or impermeable rocks.

This is a disadvantage that has from the previous hydrothermal technology that only rely on the existence of geothermal point.

Technology on Enhanced Geothermal System (EGS) is the same as in hydrothermal, geothermal can serve as a base-load power source that produces 24 hours a day, such as fossil fuel plants.

But unlike hydrothermal, EGS seems to be eligible anywhere in the world, depending on the economic capabilities of the drill depth achieved.

The good location is in deep granite that is covered by a depth of 3-5 kilometers (1.9-3.1 miles) of isolated sedimentary layers capable of withstanding longer heat.

the EGS well is expected to have a useful life of 20 to 30 years before the outflow temperature drops about 10 degrees c (18 degrees f) and the well becomes uneconomical.

Building an EGS-Enhanched Geothermal System requires the injection of millions of gallons of water - a very valuable resource, in which a geothermal enhancement system is potentially applicable.

Water is sometimes mixed with small amounts of chemicals to help liquids create and disperse better small cracks in the underground, which eventually extend the life of geothermal power plants.

But technical challenges and concerns over the cost and massive use of water are still a concern for countries with minimal water resources.

#Enhanced Geothermal System

PNNL liquid is aqueous solution and 1 percent polyallylamine, a chemical made of long carbon chains with nitrogen attachments similar to polymers understood to be used in medicine.

The liquid is pumped into the wellbore at the geothermal point.

Soon after, workers also injected pressurized carbon dioxide, which could come from carbon captured at a fossil fuel power plant.

Within 20 seconds, polyallylamine and carbon dioxide link together to form a hydrogel that extends the fluid up to 2.5 times its original volume.

The gel swelling pushes the rocks, causing an existing crack to expand as well to create a new crack.

The expansion is expected to cut half the amount of water and the time it takes to open an enhanced geothermal reservoir, which could dampen the operational costs of future power generation.

The liquids used in plants using EGS have been tested by a team of scientists. The liquid consistently creates a small and effective crack in rock samples.

Some new fractures are too small to be seen with a high resolution imaging method called X-ray microtomography.

But when they witnessed liquids such as water or injected carbon dioxide, the team saw the fluid move through rock samples that had previously been impermeable.

Fluid moves do not pass rock samples injected with ordinary water or chemical breaks of sodium dodecyl sulphate and xanthan.

The team reasoned a larger scale test could result in larger cracks.

The operational cost of Enhanced Geothermal System can also be reduced with new fluids.

With a little liquid to pump underground, the water purchased is also slightly, slightly catching water and less treatment, which means lower operating costs.

However, detailed analysis is needed to precisely measure how much liquid can be lowered at that geothermal price.

The team has also just begun a funded PNNL study to examine the same fluids for non-conventional oil and gas recovery.

The oil and gas extraction fluid used will use different polyamines related to the chemicals used in geothermal extraction liquids.

Both liquids can be stable and can withstand extreme temperatures, pressure and acidity levels. Many liquids are used for oil and gas degradation recovery, making them less effective over time.

Characteristics combined with liquids that reduce water use, toxic properties and their potential for recycling, make PNNL fluid a candidate for oil and gas extraction.

The Office of Geothermal Technology with the Office of the Department of Energy from Energy Efficiency and Renewable Energy funded this research.

The study used X-ray computed tomography and nuclear magnetic rotation resonance instrument at EMSL, the DOE Environmental Science Environmental Molecular Laboratory facility at PNNL.

Enhanced Geothermal System (EGS) is currently being developed and tested in France, Australia, Japan, Germany, the United States and Switzerland.

The largest EGS project in the world is a 25-megawatt pilot plant when geothermal power plants are being developed in Cooper Basin, Australia. Cooper Basin has the potential to produce 5,000-10,000 MW.

This post has received a 0.36 % upvote from @booster thanks to: @cutkurata.