Safety of lifting operations

THE CRANES

Inspection:

Before starting work the crane operator must check:

- The engine oil level

- Oil level of hydraulic systems

- The level of the cooling product of the radiator

- The level of the fuel tank

- The electrolyte level of the storage batteries

- Tire Pressure

Implementation of the crane:

Before positioning the crane for lifting:

• Inspect all crane devices

• Make sure there is no grease or mud in the cab, the feet must not slip on the pedals while the crane is in use.

• Adjust the seat to the best position

• Check the load torque limiter (insert the boom, turn the rotating part, lower the boom completely, lower the muffle, set the potentiometer to zero).

• Check boom angle and range

• Ensure that the power supply is perfect

• Ensure that there are no objects or obstacles that interfere with the correct operation and freedom of movement of the device.

• Ensure that the safety devices integrated, such as limit switches, are empty.

• Ensure that the slings and all lifting accessories are in good condition and properly adapted to the loads to be handled.

Commissioning of the crane:

For proper operation of the crane:

• Access your workstation using the means established for this purpose.

• The operator should not eat, drink or talk to anyone during the use of the crane.

• For handling and reversing operations, the crane operator is helped by a guide using the conventional lifting signals

• Lift loads vertically

• Avoid tipping or swinging loads

• Maneuver without brutality.

• Keep people away from the crane's operating range

• Take into account climatic conditions (such as wind thrusts)

• Check and improve the resistance of the floor by sealing shims.

• Avoid lifting loads greater than those indicated on the appliance

• Avoid transporting personnel to undeveloped appliances.

• Move cranes at moderate speeds

• Equip all cranes with fire extinguishers and medicine boxes.

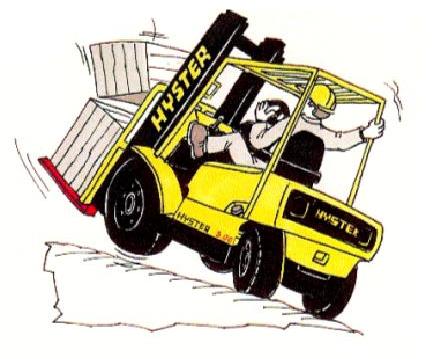

II. ELEVATORY TROLLEYS

Safety devices

Each forklift must have the following safety devices:

• Car horn

• An audible alarm when the vehicle retreats

• A blinking light visible from all sides, on the top of the cab

• Fire extinguisher

• Front and rear lighting systems

• A parking brake

Maintenance:

• The refueling of the forklift trucks must be carried out with the engine switched off.

• The forklift truck must be checked daily.

• Any forklift truck with a fault that reduces the safety level must be switched off and repaired immediately.

Driver training:

• Operators are trained before being allowed to use the forklift truck. This training focuses on the operation and the rules of conduct and safety of the forklift truck.

• The list of operators authorized to use the fork-lift truck must be displayed for all personnel.

Using the forklift truck:

• When the truck is switched off, the lift truck must be removed.

• When using the forklift truck, the driver must ensure that it is safe.

• Under no circumstances should the personnel be placed under a load lifted by the forklift truck.

• The forklift can be used for lifting personnel by means of a platform properly installed on the forks. This platform must be properly equipped and equipped with handrails.

• The forklift truck must never engage in lifting any load with another forklift or lifting device.

• Operators must not exceed the lifting capacity of the forklift truck. This is written on the trolley.

• Forklift trucks must move with the forks 30 cm from the ground.

• The forklift must not travel at speeds exceeding 8 km / h.

• The load must be transported with the tilted forks towards the rear and in their lowest positions.

• If the operator has no visibility forwards, move the truck in reverse. In any case the horn should be used whenever the visibility is obstructed.

• The forks must always be in the widest position for better load stability.

• The load must be balanced on the forks. If necessary, it will be attached to avoid accidents.

• The operator must reduce the speed when changing the direction, especially when the truck is loaded.

• The truck must be in the off position to lift or remove a load.

• When the forklift is not in use, the forks must be in the low position and tilted forward. the power supply must be switched off and the brakes applied. If the forklift is parked on a slope, the wheels must be blocked by shims.

Daily Checks

Before operating the forklift:

Check and correct, if necessary, the engine oil level, the coolant level of the radiator and the batteries.

Check the level of the fuel tank

check tire pressure

Check the safety equipment of the forklift truck

Check the oil circuit and make sure that there is no oil leakage.

Make sure all indicators are working properly

Make sure that all lights work as well as the reversing buzzer.