Knurling Tools: Adding Grip and Style to Metalwork

Knurling Tools: Adding Grip and Style to Metalwork

Introduction

In the world of machining and metalworking, precision is everything, but sometimes, it’s not just about smooth finishes and clean cuts. Knurling is a unique process that adds texture, grip, and an aesthetically appealing design to metal surfaces. Using a knurling tool, machinists can create patterns on metal components, enhancing their usability and visual appeal. In this blog, we’ll explore what knurling tools are, how they work, and their importance in various industries.

What is a Knurling Tool?

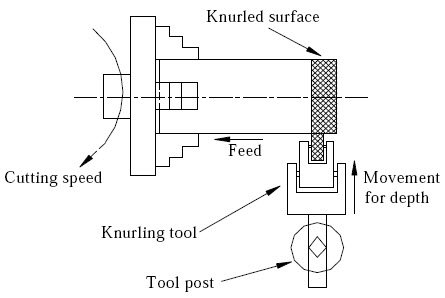

A knurling tool is a special tool used in metalworking to produce a series of ridges or textured patterns on the surface of a workpiece. Typically used on a lathe, it presses the pattern into the metal rather than cutting it. The process is common in applications where grip and handling are essential, such as handles, knobs, or screws.

How Does a Knurling Tool Work?

Knurling tools create patterns on the surface of metals through deformation rather than cutting. Here’s how the process typically works:

1. Setting up on a Lathe: The knurling tool is mounted on a lathe machine, and the workpiece is secured.

2. Positioning the Tool: The tool is pressed against the surface of the rotating workpiece.

3. Pattern Creation: As the workpiece spins, the knurling wheels or rollers, which have pre-formed patterns, press into the metal surface, leaving a textured design.

4. Finishing: The knurled surface is cleaned up and inspected to ensure even texture and quality.

Types of Knurling Patterns

1. Straight Knurling: Creates vertical or linear ridges, providing a simple non-slip surface. Commonly used on handles or knobs for easy grip.

2. Diagonal Knurling: Produces diagonal ridges that can go in either direction, often used for a more decorative effect.

3. Diamond Knurling: One of the most popular knurling patterns, where crisscrossed ridges form diamond shapes, offering a high level of grip and a visually striking texture.

Types of Knurling Tools

1. Cutting Knurling Tools: These tools actually remove material from the workpiece as they cut the knurl pattern, ideal for softer materials.

2. Forming Knurling Tools: These tools press the knurl pattern into the surface of the metal without removing any material, suitable for harder metals.

Applications of Knurling

Knurling is widely used in industries such as manufacturing, automotive, and consumer goods. Some common applications include:

• Tool Handles: Adding grip to tools like hammers, wrenches, and screwdrivers.

• Machined Parts: Providing better grip for machined parts like fasteners, knobs, and handwheels.

• Aesthetic Enhancements: Adding decorative finishes to components in automotive interiors, jewelry, and consumer electronics.

Advantages of Using a Knurling Tool

1. Improved Grip: The main purpose of knurling is to provide a textured surface that improves grip, especially in parts handled frequently.

2. Enhanced Appearance: Knurling adds a stylish, professional finish to metal components, improving their aesthetic appeal.

3. Functional Design: Knurled surfaces are used in parts requiring quick adjustments by hand, such as adjustment knobs and fastening screws.

4. Durability: The knurled texture can make components more durable, especially when the part is subjected to frequent handling.

How to Use a Knurling Tool Properly

1. Choose the Right Knurling Tool: Select the appropriate tool for your material and the pattern you want to create.

2. Set the Lathe Correctly: Ensure that the workpiece is securely mounted and the tool is aligned properly.

3. Apply Proper Pressure: Use enough pressure to form the knurl without damaging the tool or the workpiece.

4. Use Coolant: Applying coolant during knurling can reduce heat buildup, ensuring a smoother finish and prolonging tool life.

Tips for Successful Knurling

• Start with a Clean Surface: Make sure the workpiece is free of contaminants to ensure a consistent knurl.

• Check Your Speed: Slower lathe speeds are usually better for knurling, allowing more control and precision.

• Inspect the Pattern: After creating the pattern, check for uniformity and quality to ensure the knurling process was successful.

Common Knurling Mistakes to Avoid

1. Too Much Pressure: Applying excessive pressure can damage the workpiece or the tool. Start with light pressure and gradually increase.

2. Uneven Patterns: If the knurling tool isn’t aligned properly, the pattern may be uneven. Ensure correct alignment before starting.

3. Overusing the Tool: Knurling tools wear out over time. Keep an eye on the knurl wheels and replace them when necessary to maintain pattern quality.

Conclusion

Knurling tools are essential in adding both functional grip and aesthetic appeal to metal components. Whether used in industrial machinery, hand tools, or decorative pieces, knurling enhances both usability and design. Understanding how to use a knurling tool properly and the types of patterns available opens up new possibilities for machinists and metalworkers alike.

Call to Action

Have you used a knurling tool in your projects? Share your experience in the comments below, and if you’re new to knurling, try it out and let us know how it went!

This structure makes the blog both informative and engaging, appealing to machinists, hobbyists, and anyone interested in learning about knurling tools.