PROJECT REPORT ON ROBOT (BADPAKSH) : W I R E L E S S T U N N E L I N S P E C T O R

CHAPTER-I

1.1 Introduction

One of the greatest challenges faced by engineers today is the inspection, assessment, maintenance and safe operation of the existing civil infrastructure such as tunnels, bridges, roads, pipelines and much more. Nowhere is the need of the underground transportation tunnels, a large number of which have been in operation for more than half a century.

So instead of sending human inside the tunnel a small robot machine can be sent inside. Due to this the safety of the workers are guaranteed. Also there come some problems even for the robots/machine which is discussed in the limitation section of this proposal.

This research about BAD PAKSH (the wireless tunnel inspector) which is directly dedicated to the tunnel worker. According to motto, work and safety is the most important for workers for any company, due to this reason we cannot applied the worker in the risk zone, but it is also another point the completion of job is also important for company, during this period we can implement this machine inside the problem zone and we can observe the location by the help of camera which is applied on the machine and machine is also controlled by wireless system and machine kicks the videos for observer and observer can take the action after inspection like safe zone, risk zone, and safe working zone etc before the worker will be applied inside the tunnel for job and take the safe and mind blowing action. Up to now, the power transmission cables above ground has brought trouble to the reconstruction of the mansions. With the development of the underground power transmission technology, many big cities construct the underground cable tunnels to provide the extra-high voltage power. Thus, the situation has taken a favorable turn. But the cable tunnels have the drawbacks of long distance and complex landform. So, in order to guarantee the zero downtime of the cable tunnel in operation, the inspection measures must be taken in advance against the fire accident. At the same time, the poisonous gases, such as CO, CH4, and CO2 and so on, are often beyond the acceptable concentration level in the cable tunnel. Thus, it is urgent for us to do the wireless, untouchable, and online inspection in tunnels. It is a wireless technology meant for inspection the condition behind the natural disaster and other critical condition before the recue team can be sent. It can be applied as first aid vehicle and communication medium for the victims. In the present situation every year many workers lost their life in tunnel during working. So, according to the working condition and situation our main objective is to minimize it. So for this we have created and developed a technology to inspect the situation before human can reach. So, for this we have created and designed a technology called “TUNNEL INSPECTOR”.

1.2 Background

The Wireless Tunnel Inspector is a robot which is used or operated in the tunnel works for the safety of the tunnel workers. The control of this project is done by wifi module (ESP8266MOD). This module controls the required output signals depending on the varying input signals from the mobile application.

Other main component used are ADSL router, mobile application, IP camera and so on.

This robot develops its own wifi and through this the mobile phone and laptop is connected to the robot. The motion control of this robot is done by applying the necessary commands from the mobile application which is then decompile by the ESP8266MOD and robot starts to operate. The IP camera throws the video recording through the wifi and from the software installed we can review it.

1.3 Objective

The main objective of BAD PAKSH is to inspect under the condition of natural disaster and other critical condition primarily where high risk is available and chances of other major accident is possible. In such critical and dangerous condition our main motto is to send BAD PAKSH before rescue team which reduces or minimizes the other accident.

The key objectives of this project are:

➢ To supply first aid treatment and basic needs to victims trapped inside the tunnel. ➢ To inspect the tunnels and underground cables. ➢ To maintain the safety of the underground workers. ➢ To operate where the occurrence of human is not possible.

1.4 Scope of Project

The significant scope of this project can be realized in sensitive area like tunnels where the occurrence of human is not possible. This project will help to provide the safety to the tunnel workers from hazardous situation.

1.5 Methodology

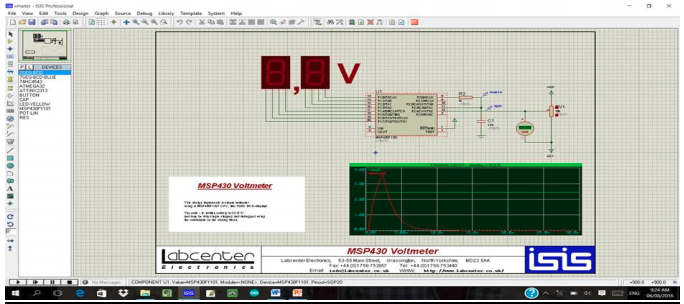

➢ Collection of different documents for wifi module, circuit components, relay driving circuit, control circuit etc. ➢ Representation of concept on a simple block diagram. ➢ Drawing the rough approximation circuit diagram by taking the reference of block diagram. ➢ Preparation of the flow chart for proper control of the components in proper time. ➢ Programming for the wifi module, setting up the software for IP camera. ➢ Programming for the android application. ➢ Simulating the circuit using PROTEUS simulator. ➢ Comparing and analyzing the output of simulation with the desired output and modifying the circuit until the required output is obtained. ➢ Fabricating the final circuit and testing it for confirmation with desired proper operation.

CHAPTER-II

Literature review 2.1 Concept about project

This project is based upon the concept that automation on can be done on tunnels and other tunnel related works.

First of all we all the members faced some difficulties in controlling the robot. Then some research/study about the topic has been done. Finally we all reach on conclusion that we have to do some work on the speed of the geared motor amd wifi module.

2.2 Specification

Specifications are the requirements for the successful completion of the project.

- SOFTWARES:

➢ Windows®10 ➢ Ms-office®2010 ➢ Arduino®1.0.3 ➢ Android SDK® - HARDWARES:

➢ IP Camera ➢ ADSL Router (LB LINK) ➢ Geared DC Motors ➢ Android mobile ➢ Wi-Fi module (ESP8266MOD) ➢ Motor driving card

➢ Laptop ➢ Battery (12v) ➢ Fibber chassis ➢ Rubber gripped Wheels Castor wheels ➢ LEDs ➢ Relay bank (12v each) ➢ Clamps ➢ Voltage divider

- PC Configuration requirements: ➢ 500 GB minimum hard disk required ➢ 14’’ monitor [not recommended] ➢ Minimum display resolution – 1024*768 or better ➢ 64 bit operating system is recommended ➢ 2GB of RAM (high speed) [not recommended]

Description about above listed equipment’s and materials are described below:

2.2.1 HARDWARES:

➢ Wifi module:

The ESP8266 Wi-Fi Module is a self-contained SOC with integrated TCP/IP protocol stack that can give any microcontroller access to your Wi-Fi network.

This module has a powerful enough on-board processing and storage capability that allows it to be integrated with the sensors and other application specific devices through its GPIOs with minimal development up-front and minimal loading during runtime. Its high degree of on-chip integration allows for minimal external circuitry, including the front-end module, is designed to occupy minimal PCB area. The ESP8266 supports APSD for VoIP applications and Bluetooth co- existence interfaces, it contains a self-calibrated RF allowing it to work under all operating conditions, and requires no external RF parts.