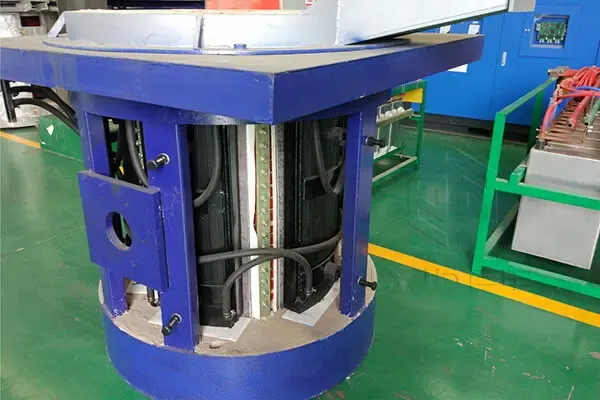

Induction heating furnace

Induction heating uses induction heating to heat the part or the whole, which has some advantages for mass production, so it is discussed here. When the current in the conductor changes, the magnetic field around the wire also changes.

Judian intermediate frequency furnace

aluminum melting point

By using the change of the magnetic field, the current can be generated in the properly placed material, so that the material is heated. The usual induction heating equipment has a coil of wire wound with alternating current.

The square or circular cross-section material to be heated is placed in the coil. The frequency of the alternating current (cycles per second) has a great influence on the temperature distribution in the heated object. Some countries have determined the basic frequency to be 50 Hz (cycles/second).

The standard frequency in the United States is 60 Hz for low frequency and 960~3000 Hz for high frequency. For some special purposes, higher frequencies are used, such as 9600 Hz and even radio frequencies. There is a skin effect in both the workpiece and the wire of the induction coil. The higher the frequency, the stronger the skin effect. At high frequencies, almost all heating processes occur on the surface of the blank.

induction furnace price

The heating rate decreases rapidly toward the center according to the law of an exponential curve. When the frequency is low, the heat generated by the surface is also the largest, and it also decreases toward the center according to the law of an exponential curve, but it decreases more slowly than at high frequencies (i.e., the heat penetrates deeper).

Based on the above facts, low-frequency heating is used for bars or billets with large cross-sections, and forging or rolling requires deep heating. This statement is applicable to the heating of any metal. High frequency is suitable for deep heating of thin bars of any metal, or for surface (layer) heating of steel bars of any cross-section.

If deep heating is required, the designer must carefully select the frequency in order to obtain an effect with high efficiency and low cost. The metal billet must be insulated from the induction coil. If the diameter of the bar or billet is small (less than 63 mm for mild steel), air can be used as an insulator, because the heating time is short. Induction heating uses induction heating to carry out local or overall heating, which has some advantages for mass production, so it is discussed here.

When the current in the conductor changes, the magnetic field around the wire also changes. By using the change of the magnetic field, current can be generated in the properly placed material to heat the material. Common induction heating equipment has a coil of wire wound with alternating current. The square or circular cross-section material to be heated is placed in the coil.

The frequency of the alternating current (cycles per second) has a great influence on the temperature distribution in the heated object. Some countries have determined the basic frequency to be 50 Hz (cycles/second). The standard frequency in the United States is 60 Hz for low frequency and 960~3000 Hz for high frequency. For some special purposes, higher frequencies are used, such as 9600 Hz and even radio frequencies. There is a skin effect in both the workpiece and the wire of the induction coil. The higher the frequency, the stronger the skin effect. At high frequencies, almost all the heating process occurs on the surface of the blank.

The heating rate decreases rapidly toward the center according to the law of an exponential curve. When the frequency is low, the heat generated by the surface is also the largest, and it also decreases toward the center according to the law of an exponential curve, but it decreases more slowly than at high frequencies (that is, the heat penetrates deeper).

Based on the above facts, low-frequency heating is used for bars or billets with large cross-sections, and deep heating is required for forging or rolling. This statement is applicable to the heating of any metal.