Post-Processing a 3D Printed Dragon Part 1: The Print

I've been exploring my creative side more recently, so for the past few days I've been working on this forest dragon model created by user dutchmogul on thingiverse. It's a very new thing for me and while I have a little bit of prior experience in woodwork & crafting this is all mostly unfamiliar territory to me, so I'm documenting this as a sort of self-journey to see where I end up with it. This is my first update with more to come!

Here is dutchmogul's dragon from the thingiverse page:

It's the basis I'm using for how I want my model to look, although it remains to be seen how well mine will actually turns out ;)

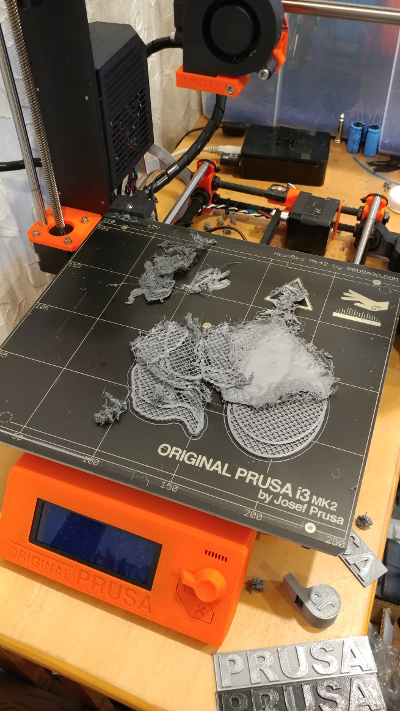

Anyway, if you check through my blog history you'll see that I had a little, um, trouble the first time I tried to print the pieces for this dragon:

Put simply, that attempt was a catastrophic failure. It failed so badly that not only did I have to clean the bed/nozzle/hotend, I also had to recalibrate all of the dimensions (XYZ) and readjust the printer's height offset from the bed so it would stick correctly again. You can understand if I was a bit hesitant to start printing this thing again, but eventually I managed to work my way back up to it.

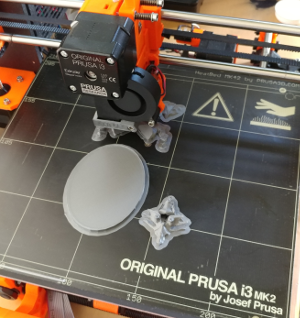

To minimize the chance of failure the second time around, I made a couple changes. First I decided not to print everything at once. Because the bed is not perfectly even, it means that a piece could be more prone to warping just by simply being in a different location (eg. corner vs the center). So, I printed in smaller batches and tried to keep everything as close to the center as I could. Second, I printed with brims:

In case you're not familiar, a brim is just an extra border you print around a model to increase it's surface area on the bed. Generally you'll print 8-10 lines or so around it and that'll help with adhesion to the bed so it'll stick better and be less likely to warp. More info on brims if you're curious.

And the result was, it worked! Well, mostly. There was still some warping that happened mainly on the body and wings, but thankfully I didn't get any more catastrophic failures like the first time, and for the most part everything looked pretty good:

woww @xerdo

very awesome post

i like it

Thank you!

3d printers are awesome

No question! It's fun to print all kinds of shapes :D