THE DIARY GAME: 7/8/2020: A MAJOR MISTAKE TO CORRECT

Dear diary,

Today started on a good note, and I went to work as expected. I got to office and realized one of the job I started inspecting yesterday was taken to 90% completion in last night.

My out fit today, pcture taken at home before going out

I got saddled with the responsibility of completing the visual weld report. For the records, the job title is: FOLLOWER CENTRALIZING PLATES. The plates, fabricated by use of 16mm and 25mm plates will be use for enforcement on pressure pipes.

Completed follower centralizing plates, picture taken in the fabrication workshop

Me in the workshop, inspecting one of the follower centralizing plates

I have done the visual check of the welding and it’s acceptable based on the standard. For structural jobs like this, we use AWS DW1.1-Structural Welding-Steel.

Now The Mistake

A major mistake was done on by our fitter on the second job I’m to inspect. The job title is C-Clamp For 54’’ Pile. For that job we have 4 pieces to fabricate.

2 pieces have equal dimensions and the next two has equal dimensions. Instead of the fitter to follow the drawing and cut based on stated dimensions, he cut 50mm partition on where he was supposed to cut 45mm. I was too busy to be on site while he did the cutting.

I, the quality manager and the project engineer have been brainstorming on the way out to correct the error. Fortunately, nobody is blaming anyone, besides, the fitter who made the mistake has been sent to Lagos for another project.

How do we solve this?

Obviously we can’t condemn we 50mm plate because of 5mm blunder. The project engineer shifted it to us in quality department to find a way out. For me I was just thinking.

Suddenly an idea came to me. I told them;

since we can’t do anything to make the hole 45mm because of how delicate the job that the clamp will be used for is, let’s leave that one to cover for the big clamp that is about to be fabricated, while we build extra dimension on the outside using electrode.

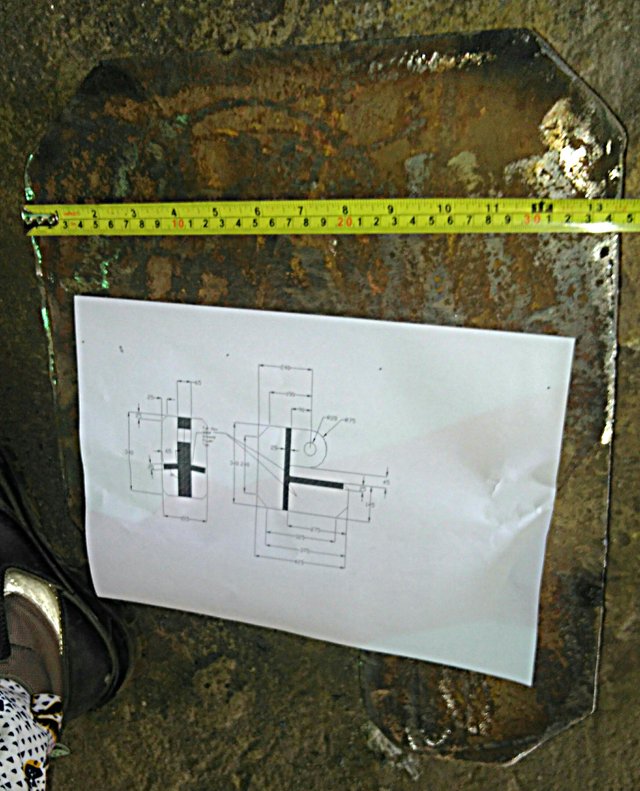

checking the dimension of the c-clamp on which the mistake was made

The slot cut 50mm instead of 45mm

What this means is that we will, by welding process, build a weld metal on the outer part of the clamp and make it 345mm(the dimension for the big one), then the new one we will fabricate will be done to take the dimension of the small one.

I know you don’t understand. Let me explain. Two of the clamp are 345mm in actual size and have a hole of 50mm each and the next two has 340mm and 45mm hole.

The fitter cut a hole of 50mm on a 340mm clamp istead of cutting 45mm. So, to correct it, we will convert the small clamp to a big one by building 5mm through welding the sides with electrode, since the big ones have not been done yet.

So, that done, we will now use the next steel material to fabricate the two small clamps.

My idea brought a lot of relieve to everyone involved, and that’s what we are going to do it.

Next

I went to the store to sort out grinding machines to be repaired. Since we have sent 20 grinding machines to Lagos for job, we need to put the bad ones in order, in case another job comes before the ones in Lagos is brought back.

Five of the machines are being worked on, by the machine technician.

Our technician working on the grinding machines

That is how my day went.

For more information about me, PLEASE SEE MY ‘THIS IS ME’ POST.

I belong to @teamg-nigeria and HERE’S OUR TEAM ANNOUNCEMENT POST.

Thank you for stopping by on my blog

This post has been rewarded by @beautychicks from @steemcurator04 Account with support from the Steem Community Curation Project."

Keep posting good content and follow @steemitblog for more updates. Keep following all the rules in the Diary Game, as well as improving your Diary post content to get more attention. Thank you, Steemit Team!

Happy birthday. Wish you many happy returns.

Thank you very much for your great job. Have a beautiful day.

Thank you for taking part in The Diary Game on Steem.

Sorry we missed the voting window on this post. An extra vote will be added to your next Diary Game post.

Keep following @steemitblog for the latest updates.

The Steemit Team