How do you understand frictional pressure losses in drilling fluid circulation?

Hello friends and STEM content lovers.

This time I am going to explain in some way the energy balance that must exist to overcome the restrictions that exist in the circulation of drilling fluid from the mud pump to the active tanks, as there are flow restriction in the different components and equipment both on the surface and downhole, ie throughout the path of the drilling fluid.

Who provides that additional force to overcome the flow restriction caused by friction?

The mud pump is in charge of supplying force that translates into an increase in pressure throughout the circulation system, since the pressure of the system not only needs to be high to circulate the drilling mud, but the pressure of the circulation system must be such that it achieves sufficient pressure to lift the cuttings cut by the bit at the bottom of the well as it is drilled and deepened in the well.

What other parameters are affected by friction?

Not only the circulation pressure of the system is affected by friction, also for example if there are operations in which the pipe is being lowered or raised, there will be a restriction to these movements to remove or insert the pipe due to friction, what is really important to evaluate in the drilling of wells is not that we know which variables are affected by friction, but which variables are influential to overcome the friction.

Already in the development of this post we have named one that is the increase of pump pressure, however it is an aspect to take care because it can overcome the fracture pressure of the formation, so other alternatives are:

Increase the density of the drilling mud.

Logically, if we increase the density of the drilling mud we are going to increase the pressures, both hydrostatic and circulating pressure, by increasing these pressures we are causing that friction can be overcome so that the fluid circulates throughout the system.

The positive of increasing the slurry density and not increasing the pump flow to obtain a higher circulation pressure is that the slurry pumps will work less forced, and in case of having to turn off the pumps in the same way we can have a hydrostatic pressure that will contain the circulation fluids.

Reducing surface components that cause restriction.

Not only friction is an opponent to the circulation of drilling mud, there are also surface components that are a restriction such as changes in pipe diameter, elbows, among others, all this detracts pressure to the system and makes you lose power to circulate drilling mud.

What is the amount of force required to overcome friction and other components that are restriction to the normal circulation of drilling mud?

This energy or force necessary to overcome the flow restrictions is called friction loss, although not only friction is the one that subtracts energy to the fluid to circulate, in general it is called this force lost by friction.

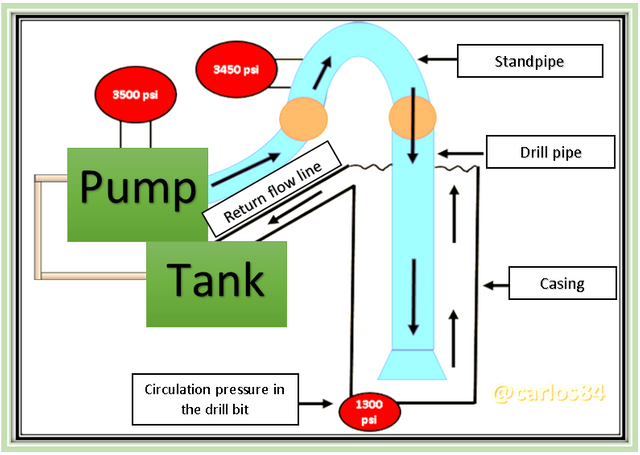

Let's see the following scheme (author's image) where you can see the path that follows the drilling fluid since it leaves the tanks until it arrives again:

Image source: Image made in PowerPoint by the author himself @carlos84.

A clear example is the diagram presented previously, as you can see the fluid comes out with a pressure of 3500 psi, however with the restrictions in the diameter changes in the nozzles and with the height of the pipes where the fluid circulates we can see that at a particular point has already decreased to 3450 psi, However, the biggest pressure drop is seen at the bottom, since the nozzles of the drill bit make the pressure drop drastically to the point that in the example of the diagram we have the example that comes out of the pump at 3500 psi and the circulation pressure in the bit is 1300 psi.

Conclusion.

If the activity we are performing is drilling, we will have a higher pressure at the bottom of the well, because when the drilling mud is circulating throughout the system, the pressure at the bottom increases because we must increase the energy to overcome friction and that translates into a higher pressure at the bottom.

If the pumps are turned off there will be a decrease in downhole pressure because it is not necessary to increase the pump flow rate to overcome friction, however the pressure exerted by the fluid being static must be such that it can withstand the pressures of the formation.

Bibliography consulted and recommended

Well Control Manual. Well Control School (WCS). Harvey, Louisiana. Year 2003.