Galvanic etching - Quick HowTo

Hi Steampunk-Lovers,

This time I’m sharing my latest experience with galvanic (or electrolytic) etching.

Since I’m into custom made electronics I often think about etching my own printed circuit board designs but until now I have never done that. If you google PCB and diy you’ll get different approaches, one using aggressive acids that eat their way through copper and one approach using a solution consisting of copper sulphite and water and current 💪

I like testing out my limits from the other side so I thought: Great, if it works with copper it’ll also work with brass which contains copper. And if it works with PCB routes it’ll work with photographs too.

So here is the recipe of a successful attempt:

- Gather all ingredients:

- a brass sheet (0.3 mm thickness in my case)

- a laser printer

- a page from a catalogue to print on (normal printing paper won’t do!)

- An iron

- Cotton cloth

- GIMP Version 2.x, it's open source

- Warm water with soap

- Copper sulphate (blue powder) and water, quantities: 1 part to 4 parts and RUBBER GLOVES!! It's important to mention that copper sulfate must not end up in the sink; it needs to be disposed properly.

- Some 20 cm long piece of metal as a conductor

- Power source that can provide 5 - 10 amperes at 3 Volts

- Matte black acrylic varnish

- Sanding paper (240 or higher) or very fine steel wool (type 0000)

- Select a picture and prepare the print with GIMP:

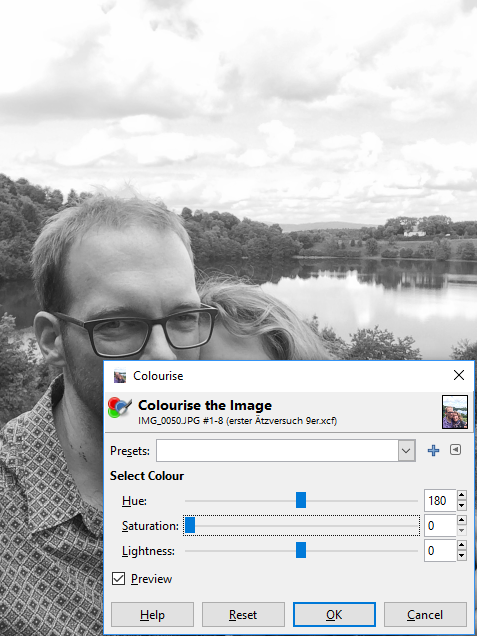

First, load it into GIMP then hit Colours > Colourise and move the "Saturation"-cursor to zero in order to remove colors. When etching you can only use "etch" or "don't etch".. that is: black and white, there is no grey.

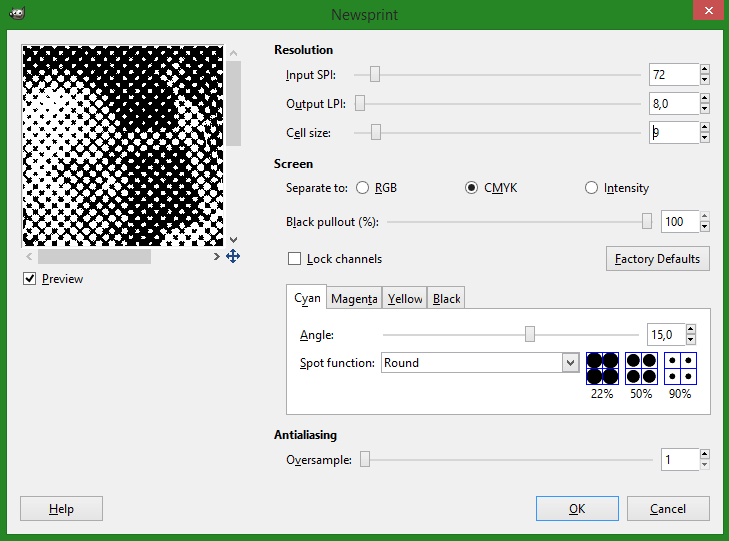

Next step that I used here was to apply a noise filter: Hit Filter > Distorts > Newsprint .... This is one approach to convert a photo into something recognizable in only black and white. A "sketchy" approach will be explained in another blog.

I tried a cell size of 9 for a printed size of 9 x 13 cm. This is subject to the paper being used for the print and to how carefully you can rub the paper off the brass sheet again.. the smaller the more delicate but the higher the resolution in the end. Seperate the colors to CMYK since you can use actually the dot color black directly.

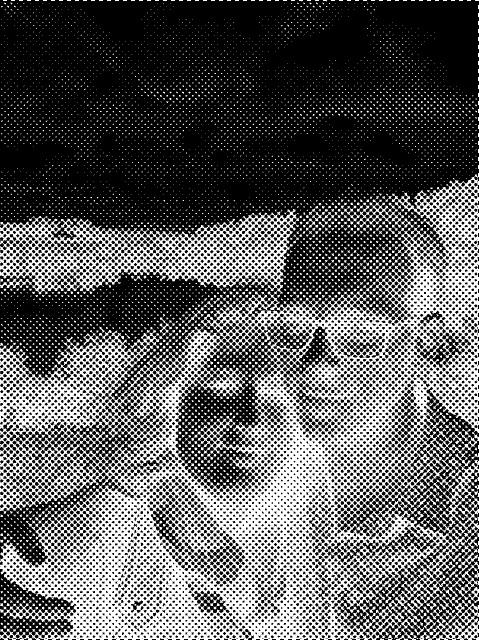

Then you need to invert the colors (only etch what is uncovered) and mirror the picture vertically. ( Colors > Invert and Image > Transform > Flip Horizontally ). Result:

- Print that picture on a catalog page with a laser printer. If your printer is having difficulties feeding the paper try scotch-taping it to a regular paper sheet. (I used the format 9 x 13 cm). Cut it out, place it on a completely clean sheet of brass (clean with isopropyl if necessary) and use the iron to make the print-out stick on there.

I used a piece of cotton cloth in between the brass sheet and the iron, put the iron on mark 3 (hottest) and moved it in small circles around the sheet for 5 minutes.

- Next, you need to get rid of the paper so that only the toner is left on the sheet. I've googled several parameters concerning the ingredient for the ideal water-soap solution that makes the paper remainders kind of resolve.. and I guess curd soap and at least an hour of soaking will do the trick. After letting the paper soften up gently rub it off trying not to rip off the toner dots.

-

NOW PUT ON THE RUBBER GLOVES.

Prepare the copper sulfate solution in a suitable plastic container (I used a random container for water filters): 4 parts water (that was 2.6 litres) and one part copper sulfate powder (650 grams). The powder needs to be completely dissolved. Be sure to avoid skin contact with the solution / powder. Then connect the 20 cm conductor to a cable that can be connected to the power source as the cathode. I used a piece of punched metal strip from the diy shop that's usually used for e. g. fitting pipes to walls.

-

Hang the metal strip into the solution on one side and connect it to the negative output (-). Then take the brass sheet, use two crocodile clips to connect it to the positive (+) output of the power source and hang it on the other side of the container with the toner dots facing the cathode / metal strip.

- The parameters may vary now according to the size of the to be etched sheet, the distance of the electrodes or the concentration of copper sulfate in the water, but I used two power supplies delivering 10 amps for 25 minutes and it removed a layer of approximately 0.1 mm of brass.

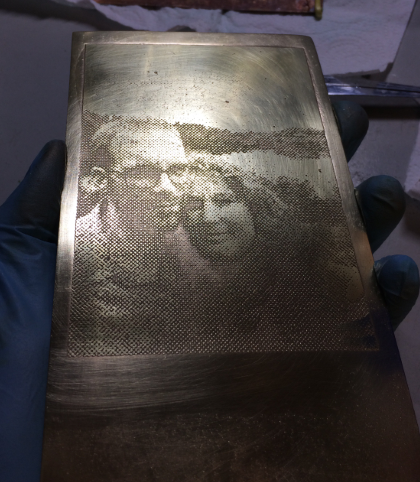

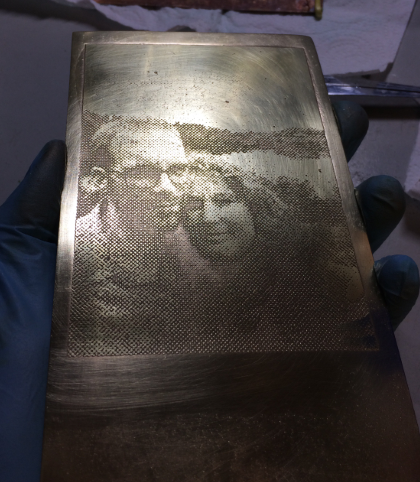

(That's the actual picture I used. I rubbed the sheet off with a very fine piece of steel wool) - Now in order to increase contrast I smeared matte black acrylic paint on the "print" to fill the lower areas. Afterwards I removed the paint from the higher areas using sand paper.

That's about it. Thought it could be done shorter here but I just realized that all the steps need their proper attention :-) So yeah, I'm thinking about integrating a new service into my business :D

Congratulations @floshmo, this post is the most rewarded post (based on pending payouts) in the last 12 hours written by a Dust account holder (accounts that hold between 0 and 0.01 Mega Vests). The total number of posts by Dust account holders during this period was 8462 and the total pending payments to posts in this category was $2422.97. To see the full list of highest paid posts across all accounts categories, click here.

If you do not wish to receive these messages in future, please reply stop to this comment.

You really made a mess in the workshop xD

Your stuff is all over the place and everyone is asking what happened lol

I moved the huge wooden box back into the shelf because I need the space. Hope that's ok with you.

Hahaha,.. sorry didn’t know you were working on Christmas 😅

ugh yeah I know, but I have to keep the money flowing.

Top! Gute Anleitung!!!! Exakt sowas meinte ich!!!! 100% Upvote! Nehme dich mit in meinen steemians best of Post auf, wenn ich darf!!! Mehr davon! Sehr nice!

@originalworks

Ich schick deinen post mal rum...das noch mehr den sehen!

Steem on

The @OriginalWorks bot has determined this post by @floshmo to be original material and upvoted it!

To call @OriginalWorks, simply reply to any post with @originalworks or !originalworks in your message!

Dankeeeee :) ich mach das gerne und wann immer ich Zeit hab Sachen aus meiner Werkstatt zu sharen, mach ich das :)

Das fehlt hier Flo!!!!

Halt alles aus deiner Werkstatt bitte fest und teile es!!!

Super nice!

thanks man! gona use this to make props for a film project

Very cool stuff. Well done

HEYYYY.. THIS IS A GOOD WORKİNG MAN !!! İ LİKE İT....

Thanks man! And to you Mr Stark

wow! you are really awesome and talented, i like your creativity . you have my vote.

Much appreciated :) thank you. There is a lot more to follow. Cheers

Good work floshmo !. Didn't know that the toner could be used as a protective varnish for etching. Do you know if it works with nitric acid or iron perchloride?

Good question @alain-bellino. I haven’t tried it but there are tutorials that use this very toner method in combination with sodium persulfate or ferric chloride.. is this of any help?

I would love to know about your experience or recent projects with etching :)

Thanks! Can't read the links but i think that ferric chloride is the same than iron perchloride.It must be tried.

I've not a great experience in etching but my daughter use it on brass jewels. On the other hand i use electrolysis to gilded and silvering antiques. I'm a bronze and silver restorer .

I've used bitumen of Judea diluted in turpentine to recreate some Art Deco etching on lightings copies. My daughter use also this technic for etching.

What an interesting job you have! Sorry for the links, I corrected them. Here is one site that describes etching with ferric chloride and sodium persulfate (one method, with different acids): http://thomaspfeifer.net/platinen_aetzen.htm (it’s in german, copy and paste the address in google translate maybe 🤓)

Thanks a lot floshmo

Hello! I am Akpan, and I work with a renowned curation guild in this community. Your post got featured in my weekly Curator Remark Anthology and I thought you might want to check out why I picked your post among the hundreds I go through on an average week.

If you appreciate my work, you may want to resteem it. Yeah, I am human, not a bot ;-)

Thank you dude, i feel flattered and I appreciate that very much. 😊

Wow ! you are So talented ; Followed you & upvoted !

Thank you dude. Stay tuned for the sketch-style approach :)