Progressive Die Stamping: A Game-Changer in Modern Manufacturing

A progressive die stamping machine has revolutionized the manufacturing industry with its advanced metalworking methods. Its efficiency and cost-effectiveness make it an indispensable tool for producing high-precision components for a range of industries, such as automotive, electronics, aerospace, and consumer products. This article explores progressive die stamping, its advantages, applications, and why Metal Stamping China has become a dominant player in the industry.

What is Progressive Die Stamping?

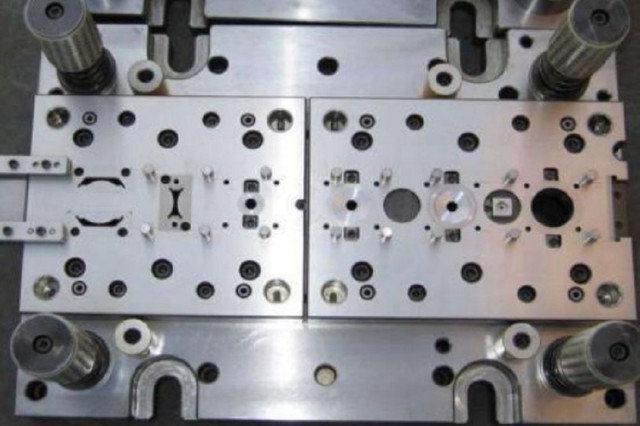

During progressive die stamping, a series of sequential operations are performed within a single die system as part of the sheet metal forming process. In this process, a strip or coil of metal is passed through multiple stations, each performing a specific operation, such as cutting, bending, punching, or coining. At the last station, the metal strip is separated from the finished part, which is then produced.

With its efficiency, precision, and ability to produce complex parts with tight tolerances, this manufacturing method is ideal for high-volume production runs. A wide variety of manufacturers around the world use the process, including Metal Stamping China, which produces high-quality, cost-effective stamped components to meet international market demands.

Progressive die stamping's key advantages

1. High Efficiency and Speed

By producing multiple operations simultaneously within a single die, progressive die stamping is capable of producing a large volume of parts in a short time.

2. Production that is cost-effective

Progression die stamping reduces labor and material costs due to its automation and ability to perform multiple operations on one die. It also minimizes waste by optimizing materials use, making it a viable option for mass production.

3. Consistent quality and precision

It is especially important for electronics and automotive, which require tight tolerances for component functionality, to use progressive die stampings because of their uniformity and precision.

4. Material and design versatility

It can handle a variety of metals, including stainless steel, aluminum, copper, and brass. It can also accommodate intricate part geometries that would be difficult or expensive to achieve with other metalworking processes.

5. Lower labor and handling costs

A highly automated process reduces labor costs, human errors, and workplace safety by reducing direct contact with heavy machinery.

Progressive die stamping applications

1. Automotive Industry

A progressive die stamping process is widely used in the automotive industry for manufacturing brackets, connectors, clips, and engine parts. The process guarantees high durability and precision, making it an ideal choice.

2. The electronics industry

Modern electronic devices require miniature, high-precision parts made by progressive die stamping, from connectors to terminals and shielding components.

3. The aerospace industry

To meet the stringent quality and safety requirements of aerospace applications, progressive die stamping manufactures lightweight, high-strength components.

4. Medical Equipment

Precision and consistency are crucial to medical devices, which is why progressive die stamping plays an important role in producing surgical instruments, implants, and other medical equipment.

5. Goods for Consumers

Progressive die stamping is used in everyday items such as household appliances, battery contacts, and hardware components because it is cost-effective and reliable.

Metal Stamping China's Role in the Industry

A well-established infrastructure, skilled workforce, and advanced technology have helped China become the world's leader in metal stamping. By taking advantage of economies of scale, manufacturers are able to offer high-quality products at competitive prices in the country's metal stamping industry. For precision-stamped components that meet international standards, many global companies turn to Metal Stamping China.

Due to their investment in automation and innovation, Chinese manufacturers are able to handle complex designs and high-volume production efficiently. China remains at the forefront of providing stamped parts for diverse industries as the global demand for precision metal components continues to grow.

Die stamping trends in the future

1. Industry 4.0 and smart manufacturing

With the integration of digital technologies, IoT (Internet of Things), and AI-driven automation, progressive die stamping is becoming more efficient and accurate. Production lines are optimized for real-time monitoring and predictive maintenance by smart factories, which reduces downtime and increases productivity.

2. Eco-Friendly Practices and Sustainability

As environmental concerns grow, manufacturers are focused on reducing waste and adopting sustainable practices. Progressive die stamping contributes to this effort by optimizing material utilization and minimizing scrap.

3. Advanced Materials and Coatings

New materials and coatings are being developed to enhance durability, corrosion resistance, and performance, including lightweight alloys and high-strength materials.

4. Enhancing customization and prototyping

Using design software and prototyping technologies, manufacturers can quickly develop and test custom die designs, reducing lead times and increasing flexibility. Get more info about Deep drawing.

In conclusion

By offering high efficiency, cost savings, and precision, progressive die stamping has continued to shape a wide range of industries. Among its uses are automotive, aerospace, electronics, and medical devices. Providing high-quality stamped components to meet the increasing demands of modern manufacturing, Metal Stamping China has become a key player in the global market.

As technology advances, the future of progressive die stamping looks promising, as smarter, more sustainable, and highly automated production methods drive the industry forward. An effective and reliable metal stamping solution can maximize production and maintain a competitive edge in businesses that are looking for a cost-effective and reliable metal stamping solution.