SLC | S21W3 | Costs for entrepreneurs - Costing methods.

Greetings from

Sitaraindaryas (Mahnoor)

Hello, i hope all of the members and fellows of steemit will be fine and happy and all will be happy to participating in these learning challenge. Now am also here to participate in the learning challenge that is organized by @yolvijrm for all steemian.

What are costing methods and what is their importance?

Costing methods are systematic procedures for determining the cost of producing a product or service. These methods allow costs to be assigned and calculated accurately and objectively. We can say in the importance of costing methods that it is helpful for determining the sales price such as costing methods help us to calculate the minimum sales price to ensure profitability. It is help us to control cost that's allows us to identify the areas for improvement and optimize processes to reduce costs.

They provide accurate information to make informed decisions about production, pricing and investment. They help us in the analysis of our profitability and they help us to evaluate the profitability of products or services. They help us in the financial planning. They facilitate the financial and budget planning. They identify opportunities to improve efficiency and productivity. And they allow competitive prices to be established in the market.

There are many types of costing methods such as, the Job order costing, Process costing, Absorption costing, Direct costing and Standard costing etc. We gave a lot of benefits of implementing these costing methods because they improves accuracy in cost determination and reduce costs and increase efficiency these methods can be improve and increase profitability as well. In short, the costing methods are essential for any company seeking to optimize it's processes, reduce the costs and increase the profitability.

Explain the difference between the job order and process costing methods.

This method is used for customized products or services, where each work order is unique and has specific characteristics. Each work order is treated as an individual project. Direct and indirect costs are accumulated per work order. Costs are assigned to each work order according to its complexity and requirements. It is used for products or services with significant variations, such as the Consulting Services, Construction projects, Design and manufacture of customized products etc.

This method is used for mass-produced products or services, where production processes are standard and repetitive.Costs accumulate in each production process. Costs are assigned to each process according to its contribution to production. It is used for products or services with similar production processes. It allows the identification of costs by process and the optimization of production. The Manufacturing of mass-produced products, Food and beverage production and Textile and clothing manufacturing are the best examples who used this method.

In summary of this question, the job costing method is used for the customized products such as the the consultant service, construction & customized products company and the process costing method is used for the mass produced products such as cars, food products, and textile Industries etc.

Research and explain, to the best of your understanding, two costing methods different from those explained in this class.

I will be happy to explain to you two costing methods that are different from those explained in class. Here in the below i discuss one of them.

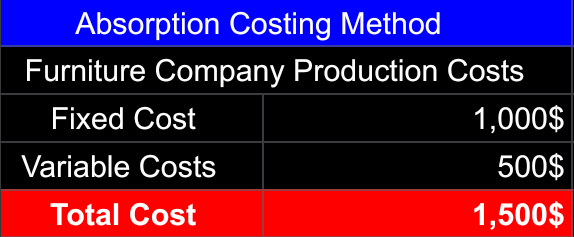

This method involves assigning all production costs, both fixed and variable, to each unit produced. The objective is to determine the total cost of production and assign it to each unit. Through this method we can assign all production costs to each unit. We can includes fixed and variable costs. It is used to determine the total cost of production.

The main benefit of this method is that it allows to determine the total cost of production and help to set sales prices. But it can be complex to implement. It does not distinguish between relevant and non-relevant costs.

For Example: A furniture factory produces 100 chairs in a month and its production costs are mentioned in the below sheet.

So, the cost per unit would be : = $15 ($1,500 ÷ 100 chairs).

So this is the Absorption costing method who determine the costs for the Furniture Company Production for per unit.

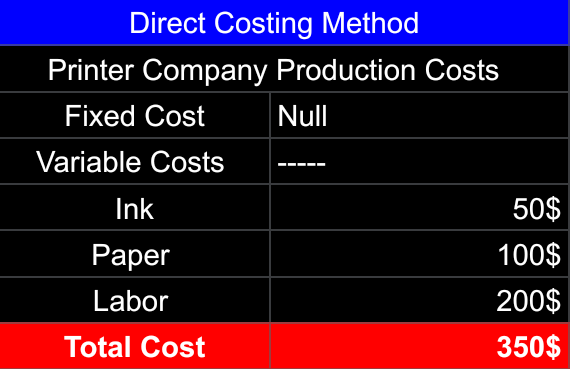

This method consists of assigning only variable costs to each unit produced, excluding fixed costs. Through this method we can assigns the only variable costs to each unit by excludes fixed costs. It is used to determine the variable cost of production. It allows to identify the variable cost of production.

It helps make decisions about production and prices. But It does not consider fixed costs and may not reflect full cost of production.

For example a printing company produces 500 brochures and it's variable costs are the ink, paper and labour. And i determine these costs in this below sheet.

So, the cost per unit would be = $0.70 ($350 ÷ 500 brochures)

In the summary of this question, the absorption costing method assign all the production costs to the each unit, while the direct costing method only assign the variable costs. Both methods have advantages & disadvantages, the choice will be depend on the company's objective and it's needs.

Perform the costing by work orders, according to what was explained for a cake manufacturing business,

For the costing of cake manufacturing business i choose the Job Costing for a Cake Manufacturing Business. Because in the cake manufacturing we have to track the cost of each cake separately. So we have to track each batch separately and the purpose is that the cake can be for a different customers or different events.

In our cake manufacturing business, each cake order is and is treated as a separate job. For example, a customer orders a customized birthday cake with a specific size and a special decoration. .

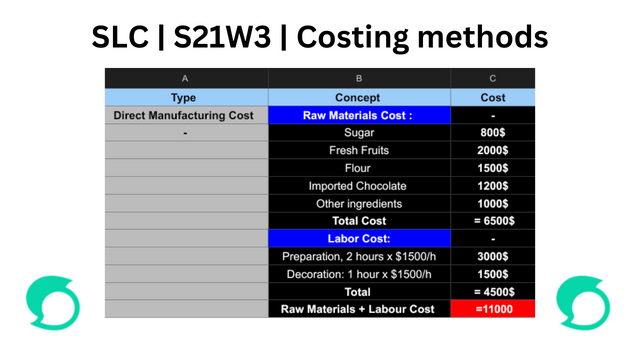

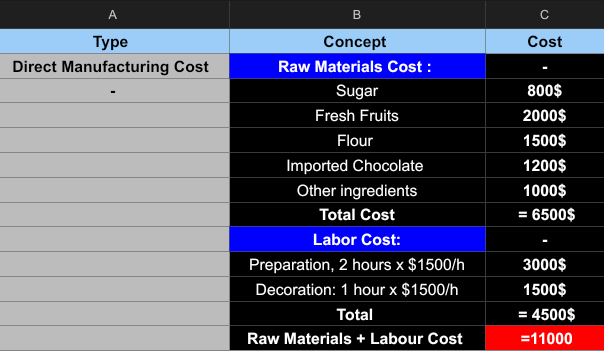

Direct costs:

Direct cost in the cake manufacturing business are the raw material (Flour, Sugar, Chocolate, Fruits) & the labour cost that is determine in the below sheet.

The direct manufacturing cost of cake manufacturing business is 11000$.

Indirect costs

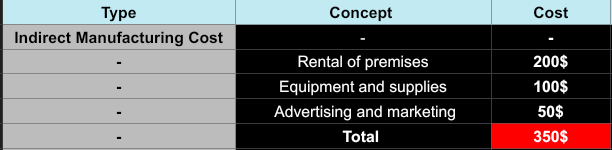

Now we track the indirect manufacturing costs of this business, that's include the Rental of premises and Advertising and marketing that's i determine in the below sheet.

Here you can see that the total indirect costs of cake manufacturing business is $350 of per month. Now am going to calculate the total cost of work order.

| Direct + Indirect Costs | = 11,350$ |

|---|

Unit Cost

Now after calculate the total cost of work order i will divided it to the amount of my orders that is 20 so, the sales of per cake is 567.50$.

Sales price: $11,350 / 20 servings = $567.50 per serving

Now this is the end of my post i hope you all are happy to reading my post and all will be appropriate my efforts to writing on costing methods. Now i am going to invite my friends @suboohi, @ydavgonzalez, @kouba01 and @josepha for participating in this challenge.

Regards,

Sitaraindaryas

Thank you!

Greetings @sitaraindaryas

1.- You have shared the definition and importance of cost methods, making it clear that these allow knowing the calculation of the cost of a product.

2.- You have presented the differences between job order and process costing methods. To be more original, we could say that the difference is in the scope of production, the job order costing method is limited to the customer's requirements; while the production costing method is subject to the set (in general) of executed orders related to the production of a product or service.

3.- You have presented two types of cost calculation methods, the first one named “By Absorption”, which generates an easy register limiting the structuring of costs to fixed and variable expenses; and the second one “Direct Costing”, which leaves aside the fixed costs at the moment of adding up the production costs, taking into account only the direct factors to the production of the product.

4.- You have selected an ideal cost method for the case, each cake has a different design and difficulty, therefore, the cost of labor and raw materials varies.

Thanks for joining the contest

Thank you so much for your review.

As an entrepreneur, cost reduction does not mean eliminating costs at all, but rather spending the right amount in the right place.

Finally good luck for the contest.

You have explained the different casting methods very well in your post. Along with clarifying the difference between job order and process costing, you also comprehensively explained absorption and direct costing. Choosing job casting for cake manufacturing was a right decision as every cake has its own nature and design. Your hard work and research is appreciated. Wish you all the best for this competition!