All About Compressors: How They Work, Types, and Practical Applications

All About Compressors: How They Work, Types, and Practical Applications

Introduction:

Compressors play a vital role in multiple industries, powering tools, inflating tires, and supporting heavy-duty machinery. They come in many types and sizes, each designed for specific applications. Whether you’re new to compressors or seeking detailed insights, this guide will break down what they are, how they work, and which types suit different needs.

- What is a Compressor?

A compressor is a device that increases the pressure of a gas (typically air) by reducing its volume. They are widely used in both domestic and industrial applications, making it easy to perform tasks that require pressurized air or gas.

Key Components of a Compressor:

• Cylinder/Piston: Responsible for compressing the gas.

• Motor: Powers the movement of the piston or rotors.

• Tank: Stores the compressed air for use.

- Types of Compressors

There are several types of compressors, each suited to different applications. Here’s an overview of the most common types:

• Reciprocating Compressor: Uses a piston to compress the air. Suitable for small to medium applications like automotive repair or light industrial tasks.

• Rotary Screw Compressor: Uses two helical screws to compress the gas, known for continuous operation, and is widely used in large industrial setups.

• Centrifugal Compressor: Compresses air through a rotating impeller, ideal for high-capacity applications, like HVAC systems or chemical plants.

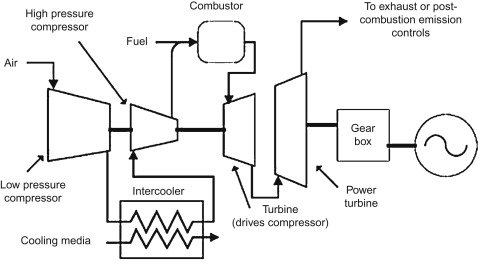

• Axial Compressor: Common in jet engines and turbines, these compressors handle a high volume of air but are not commonly used for commercial applications.

- How Do Compressors Work?

The working principle of a compressor depends on its type, but the core idea is the same: reduce the volume of a gas to increase its pressure.

Basic Steps:

1. Intake of Air: Air or gas enters the compressor through an inlet valve.

2. Compression Process: The air is compressed by reducing its volume via a piston or screw mechanism.

3. Storage: Compressed air is stored in a tank for on-demand usage.

4. Release: When required, compressed air exits the tank at high pressure for various applications.

Each type has its own method of achieving these steps, but the fundamental process is similar.

- Applications of Compressors

Compressors are versatile and can be used in numerous ways, such as:

• Industrial Applications: In factories, compressors power pneumatic tools, packaging equipment, and conveyor systems.

• Automotive Repair: Many garages rely on compressors for air tools, tire inflation, and spray painting.

• Home Improvement & DIY: Compact compressors are great for home projects like inflating tires, power-washing, or nail-gun work.

• HVAC Systems: Compressors are crucial in heating, ventilation, and air conditioning to regulate indoor climates.

• Refrigeration: They are also used in refrigerators and air conditioners to compress refrigerants.

- Choosing the Right Compressor

Selecting the right compressor depends on several factors:

• Usage: Determine whether you need it for light DIY tasks or heavy-duty industrial work.

• Capacity and Power: Industrial jobs may need higher pressure and continuous operation, whereas home compressors can suffice with less power.

• Portability: Consider portable compressors for quick tasks or stationary ones for continuous, high-powered needs.

• Noise Level: Some compressors, like rotary screw types, are quieter than reciprocating ones, making them suitable for noise-sensitive environments.

- Maintenance Tips

Proper maintenance is key to extending the life of your compressor:

• Check Oil Levels (for oil-lubricated compressors): Ensure it’s topped up regularly.

• Drain Moisture: Compressors collect moisture; regularly drain it to prevent rust.

• Change Air Filter: A clean filter ensures efficient airflow and prevents clogging.

• Inspect Belts and Hoses: Look for signs of wear and tear to avoid unexpected breakdowns.

Conclusion:

Compressors are incredibly useful and versatile tools in many fields. Whether you’re a DIY enthusiast or running an industrial setup, choosing the right compressor and maintaining it well will make your tasks easier, safer, and more efficient.

Do you use compressors in your daily work or projects? Share your experiences or ask questions in the comments below!