Bed CNC Machines: Precision Engineering on a Larger Scale

Bed CNC Machines: Precision Engineering on a Larger Scale

Introduction

Computer Numerical Control (CNC) technology has revolutionized the manufacturing industry, enabling machinists and manufacturers to produce highly precise components with ease. Among the various types of CNC machines, the Bed CNC machine stands out for its ability to handle larger and heavier workpieces. In this blog, we’ll explore what Bed CNC machines are, how they work, and why they are essential in various industrial applications.

What is a Bed CNC Machine?

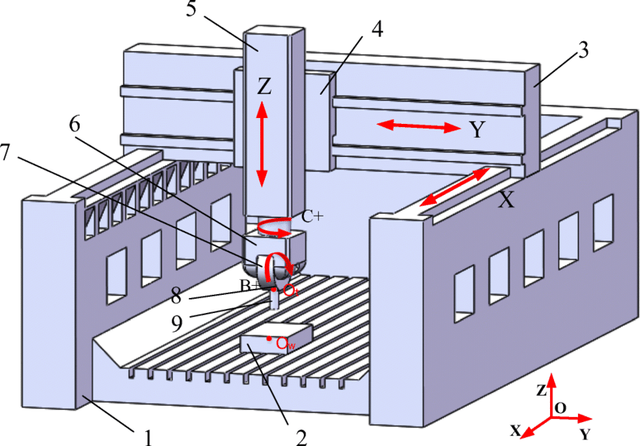

A Bed CNC machine, often referred to as a bed mill or bed-type CNC milling machine, is a type of CNC machine where the workpiece is stationary on the machine’s bed while the cutting tools move around it to perform the necessary operations. Unlike traditional CNC machines where the table can move in multiple directions, the bed-type design allows for better handling of large, heavy materials, which are securely fixed during the cutting process.

Key Features of Bed CNC Machines

1. Fixed Workpiece: The workpiece remains fixed on the machine bed, providing greater stability for machining large and heavy materials.

2. Moving Toolhead: The cutting tool moves along multiple axes, typically X, Y, and Z, to perform milling, drilling, and other operations on the workpiece.

3. Rigid Construction: Bed CNC machines are built with a solid and rigid structure to withstand the weight and size of large materials without compromising accuracy.

4. Enhanced Load Capacity: These machines are designed to support heavy-duty machining tasks and can handle large, bulky workpieces with ease.

How Bed CNC Machines Work

The operation of a Bed CNC machine revolves around precise, computer-controlled movements. Here’s a simplified breakdown of the process:

1. Workpiece Setup: The large workpiece is mounted securely on the stationary machine bed.

2. Toolpath Programming: Using specialized CNC software, the machinist programs the machine with the exact toolpath to follow based on the desired cut or design.

3. Cutting Tool Movement: The toolhead moves along the pre-defined X, Y, and Z axes to perform various operations, such as milling, drilling, or contouring.

4. Precision Cutting: The CNC system ensures that the cutting is accurate and consistent, even for complex shapes or large-scale components.

Applications of Bed CNC Machines

Bed CNC machines are widely used in industries where large, heavy parts need to be machined with high precision. Common applications include:

• Aerospace: Manufacturing of large, complex aircraft parts.

• Automotive: Machining of engine blocks, chassis components, and transmission parts.

• Industrial Machinery: Production of machine tool parts, industrial equipment, and large fixtures.

• Construction Equipment: Creating structural components for heavy machinery like cranes and bulldozers.

• Custom Metalwork: Ideal for workshops that need to machine large custom parts for various projects.

Advantages of Bed CNC Machines

1. High Precision: CNC technology ensures precise and repeatable machining, which is crucial for industries like aerospace and automotive.

2. Large Workpiece Handling: The fixed bed design allows for the machining of larger, heavier parts that may be difficult to manage on other CNC machines.

3. Stability: Since the workpiece remains stationary, there’s less risk of movement or vibration during machining, ensuring a higher level of accuracy.

4. Versatility: Bed CNC machines can perform a wide range of operations, including milling, drilling, tapping, and contouring, making them versatile for different projects.

5. Increased Productivity: With automated controls and the ability to handle large materials, Bed CNC machines can significantly reduce production times.

Choosing the Right Bed CNC Machine

When selecting a Bed CNC machine for your workshop or manufacturing facility, consider the following factors:

1. Workpiece Size: Make sure the machine’s bed size and weight capacity can accommodate the size of your materials.

2. Axis Travel: Check the maximum travel distance for the X, Y, and Z axes to ensure the machine can handle the full range of your operations.

3. Spindle Power: The spindle’s power will determine how effectively the machine can cut through tough materials like steel or aluminum.

4. Software Compatibility: Ensure the machine’s CNC control system is compatible with your preferred CAD/CAM software.

5. Precision and Tolerances: Choose a machine that meets the precision and tolerance requirements of your specific projects.

Maintenance and Care of Bed CNC Machines

Like all high-precision machinery, regular maintenance is crucial for ensuring your Bed CNC machine operates smoothly and lasts longer. Here are some maintenance tips:

• Clean the Machine Bed: Regularly clean the machine bed and surrounding area to prevent dust, debris, and metal shavings from causing damage.

• Lubricate Moving Parts: Ensure all moving components, especially the spindle and axis bearings, are properly lubricated to reduce wear and tear.

• Inspect Toolheads: Frequently check the cutting tools for wear and replace them when necessary to maintain precision.

• Software Updates: Keep your CNC software updated to take advantage of the latest features and performance improvements.

• Regular Calibration: Calibrate the machine periodically to ensure the accuracy of its movements and cuts.

Conclusion

Bed CNC machines are an essential tool for industries that require the machining of large, heavy, and complex components. Their rigid design, combined with CNC precision, allows manufacturers to achieve high-quality results while maintaining efficiency. Whether you’re in aerospace, automotive, or custom metalwork, a Bed CNC machine can greatly enhance your machining capabilities.

Call to Action

Have you worked with Bed CNC machines? Share your experience or any tips you have for others working in this field! If you’re considering investing in one, feel free to ask questions in the comments section below.

This blog structure offers a clear and comprehensive overview of Bed CNC machines, making it engaging and informative for both professionals and newcomers to the field of CNC machining.