An Inspired Cacti Fence

It was a good day when I got the call from my favorite interior designer of all time Jacques Grange asking to meet and discuss a collaboration.

Jacques is a French designer who made his name as a young designer collaborating with Yves Saint Laurent on the design all of Yves and Pierre's 6 homes throughout the world. These homes are museum quality and ooze with timeless creativity. He has many big names under his belt like Paloma Picasso and the Olsen twins.

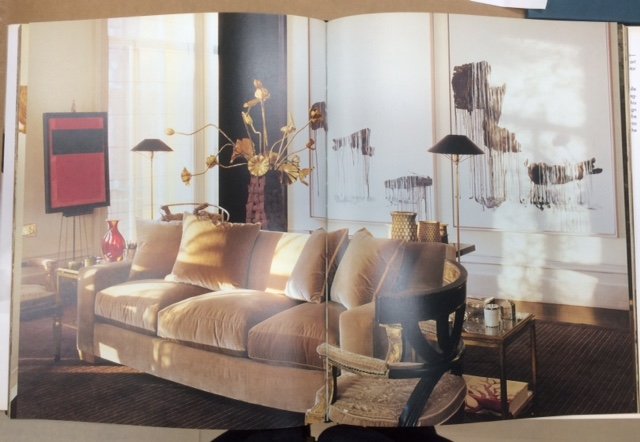

I hesitate to show any photos of his work without showing many because it’s hard to get a sense of the magic from a few but here are 2 as a point of departure.

What makes Jacques’ work not just design but genius is that he approaches every space like an artist and doesn’t have a “style” per se. He responds to each client and space with a fresh and courageous creativity that is rare. Love the guy, love his work and my heart still leaps at the mention of working with him.

His client was building an outdoor hot tub on the side of her house. Because it’s built on a platform with a steep drop off on one side, building codes required a fence around the area for safety. The client and Jacques had considered the work of metal artists, bamboo artists and others to construct this fence but they hadn’t found what they wanted.

Judging from the other art at this home (Richard Serra, Andy Goldsworthy…), I think I can safely say that the artists previously asked were more accomplished and more talented than I, but my good fortune was that Jacques remembered me and my willingness to try to make just about anything in ceramics. So when he asked, if we could make some kind of ceramic fence that met code, while also being an art piece I of course said “yes”!

We looked at a lot of books and photos and brainstormed. When he showed me a photo of the charming row of cacti in front of Frida Kahlo and Diego Rivera’s houses in Coyoacan, Mexico City, this sparked our excitement and we could both imagine how these were the perfect inspiration for a ceramic cacti fence.

I went back to Portland and worked out the details of the concept including talking with the builder and the architect to ascertain the specifics of the code for a fence in this location - height, distance between each “post”, and how deep into the ground they had to be anchored.

The wall from the back showing the 12' drop off, photographed during the installation process.

A few months later I returned to the site with color samples I’d made and constructed a mock-up of cardboard cylinders of the approximate heights and diameters so that Jacques, the client and I could get a sense what this idea would look like. It worked and even the cardboard version looked pretty cool!

(wish I had photos of this but as I recall I was too nervous on this trip to remember to take photos)

There would be a total of 57 “cacti” ceramic cylindrical sculptures . The heights of each would run between 4’ ft and 5-1/2” feet tall and each diameter would be either 4”, 5” or 6”. The variation in height, width and glaze would create a rhythmical variation. The installation would feel plant-like and the glazes would harmonize with the context but also be rich with depth, color and texture when seen up close.

Back at the studio 4 of us began making these pieces. Although we knew it would be a challenge and a lot of work, we had no idea what we were in for! My often naive enthusiasm and ambition tend to lead me to believe that I can take on things that I’ve never done before and figure it out. Well I always do and we did it this time as well but it wasn’t easy!

First I worked with a local clay company to develop a frost-proof clay body. To make the forms we used a large pug mill to extrude them with a special die we designed with Peter Pugger (the pug mill company). The process of loading enough clay, creating enough pressure to close up the seams around the die and extruding the forms was tricky and physically difficult. We had to build a special table and enlist the help of a talented woodworker friend to create several jigs to manage the dynamics of receiving these very heavy hollow tall and narrow cylinders and then tipping them up and moving them around without distorting or damaging them.

After each form was pugged, we hand-built the top and smooth and compress and smooth and compress the entire surface again and again. They had to dry very slowly and evenly so we controlled this by wrapping the cylinders in plastic with varying tightness.

I bought a special kiln called a “Transformer Kit” which is 2 kilns that operate independently or they can be stacked to create one very tall kiln. When stacked the computers are linked and can communicate and adjust the temperature of the elements to insure even heat. At the time this was a wonderful innovation since tall kilns have notoriously uneven heat even when a vent is used. Even and accurate firing temperature was essential given that these sculptures would be outside and need to withstand the elements including frost.

Our biggest technical problem was cracking. The pieces cracked at every step in the process so we continually worked to minimize this with compression, our handling, careful drying, and “magic water” (trace amounts of sodium silicate in water) to help bind the clay during extrusion. Although we made lots of improvements, we still had to make about double the amount of sculptures to yield the amount we needed.

These pieces in process inhabited every spare space in my studio! Here against a random wall.

After the final firing, each bottom needed to be cut and leveled with a tile saw and then ground down. We had a friend build special giant well-crafted crates that cradled each piece in foam and wood. They shipped across the country freight and all arrived safe and sound.

We had consulted with a structural engineer, architect and the contractor to fashion the infrastructure for the installation. The sculptures slid on to poles wrapped in foam which were embedded in the stone wall and served to anchor the pieces. These poles were installed by the contractor before we put the sculptures in place.

The simplicity of the forms coupled with stunning glazes amidst a highly textural stone wall, bamboo, patio, and water create an unusual and striking aesthetic and we were all very very pleased with the result.

Spanning 10 months from concept to completion, each sculpture was placed 4” apart to meet code requirements. Materials were selected to withstand the extreme weather conditions on the waterfront location. We completed our installation a day before Hurricane Sandy struck, and were extremely pleased that the installation remained in perfect condition despite the historic super storm.

What I enjoyed most about this project:

- The amazing spirit and can-do attitude that permeated my team who helped me at every step of making these sculptures.

- Working with Jacques and my client, their belief in me was profound and changed me!

- Discovering that I knew more than I realized and growing a deeper trust of myself as an artist technically and aesthetically.

- I still enjoy looking at the photos and am proud of the work we did.

Biggest challenge(s):

It had been years since I had built anything in ceramics bigger than 10” and mostly I’d spent the previous 20 years making more or less flat ceramic forms like tile. I had to be very careful and thorough in each of the technical considerations. On top of this pressure was fact that this was a very high stakes project and making mistakes here could have had big consequences for my reputation. With all of my worrying and going over details, I’m not sure I had a decent night of sleep all year!

Solving all of the dozens of technical challenges that arose in making these cylinders. Initially, I tried to find someone else to make these forms who might be more experienced with something similar. Everyone I asked said that they didn’t want to do it because it was too technically problematic. And they were right - we made over 170 cylinders to yield the 80 good ones we chose from.

What I learned:

I learned a lot from being involved in such a high profile project where every single piece of minutia has to be of the very highest standard. Usually I ship my work and don’t get to see the ins and outs of the rest of a project. This was different since I had to visit the site regularly over a period of 8 months and this meant witnessing a truly amazing group of talent including architects, builders, garden designers, stone masons and more on the site. I had rarely if ever experienced such a high standard of quality and talent in every single person involved. For example, the stone wall adjacent to the sculptural fence was hand carved by 6 extremely talented stone masons who worked out there rain or shine with their chisels and hammers for months.

Occasionally a client is wiling to pay the cost of creating something extraordinary and this has given me lots of hope.

So nice!

Thank you @zionuziriel!

Your welcome <3

wow

My favourite thing - taking something functional and simple then making it beautiful. You nailed it :D

thanks @handsolo!