Cane Based Bioethanol Can Overcome Energy Crisis

In last week's post, I discussed the use of bagasse for friction material in the process of making motorcycle brake lining. It turns out that bagasse is also very potential if used as fuel of vehicles and power plants, especially in Indonesia, given the abundance of cane produced by sugar mills in Indonesia.

Seeing the many problems in Indonesia that has not been completed until now, this brilliant innovative idea emerged and pushed me to long to this platform. Coupled with a recent study which says that the bagasse can be used as a substitute for electrical energy.

The Problem

The higher population growth in a region is resulted in the need for considerable electrical energy. This is because everyone has a need for different energy quantities, such as washing machines, kultas, television, air conditioning, fan, computer, handpone and so forth. That's to say that almost all human activities require and run using electricity. In addition, the high electricity tariffs be interesting to be studied and discussed. And according to the authors, it is important to discuss in order to find alternative soslusi in terms of adequate supply of current and electrical power.

According to a study conducted by Badger, bagasse can produce as much bioethanol 0.001436 kg / L . It shows that the amount of bioethanol from bagasse is very high.

Bioethanol is a clean and relatively affordable biofuel used in some countries as a substitute for Fuel alternatives. Bioethanol produced from starchy foods is called first generation bioethanol. First generation biofuels compete with food and feed. To avoid competition, second generation bioethanol needs to be developed. One of the countries that produces bioethanol from sugarcane or sugar mill waste after sugar produced is Brazil. In addition the Swedish country is also much more advanced in producing and using ethanol.

Bagasse As Fuel and Power Plant

1). Electricity

Electricity is an energy that is important and so influential in human life because electrical energy serves to move segela electronic devices and make the work of human beings easy. Electricity is a series of physical phenomenaa series of physical phenomena associated with the flow of electrical charges.

Sources of electrical energy can be generated through several methods and technologies so that various types of power plants are beginning to emerge in today's modern era. This can not be separated from the development and progress of modern science is characterized by the presence of various scientific theories based on experiments conducted by scientists in the 19th century. Modern science has given a big change in human life today. With innovative modern science, human beings think critically and continue to produce innovative value-added products. Organic materials that are generally waste factory waste can be processed and used to generate electrical energy, animal feed, and so forth.

2). Power plants

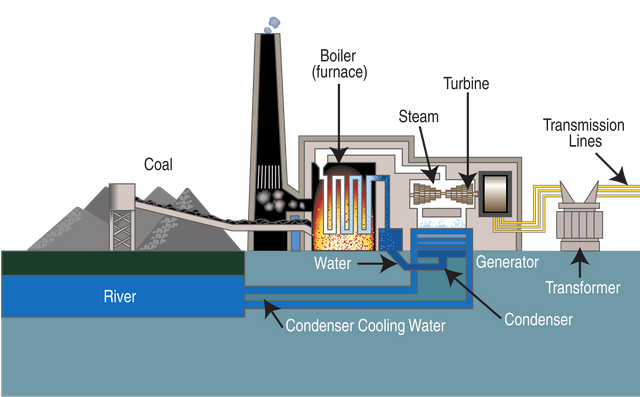

Principle of work of power plant, generator is the main component used to convert mechanical energy into electrical energy by using principle of magnetic field and conductor of electricity. Generally the generator engine on the power plant is activated by using various energy sources.

3). Bagasse

Bagasse is one of sugar mill waste that can be used and utilizated in power plants because fiber and chemicals present in bagasse are very possible to use to generate electricity.

In a study conducted by the Indonesian Sugar Plantation Research Center recently, in his research report stated the quantity of bagasse produced from a sugar factory as much as 30% of the weight to sugar cane with moisture content of about 50%. In addition, the dry material of bagasse is made up of 47% C (carbon), 6.5% H (hydrogen). O (oxygen) 44% and ash 2.5%. Per 1 kilo gram of bagasse contains 2.5% sugar with a heat value of 1.825 kcal. This calculation is in the Pritzelwitz formula (Hugot, 1986).

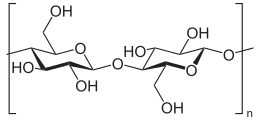

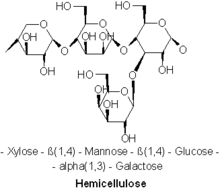

To know the chemical element of bagasse, be done the cleaning and after that proceed with drying technique. After analyzed it found that bagasse contains 45-55% of cellulose, 20-25% hemicellulose, 18-24% Lignin, 1-4% ash, and 1% wax <1 %. From the analysis of bagasse materials is very possible use as a source of fuel and for bio-based building materials, namely biomass and bioethanol based bagasse.

Cellulose is often used to produce paper and paperboard because it has crystalline, strong, and not easily hydrolyzed properties, whereas hemicellulose has a random amorphous structure with little strength and is easily hydrolyzed by dilute or basic acids as well as various hemicellulase enzymes. [Source]

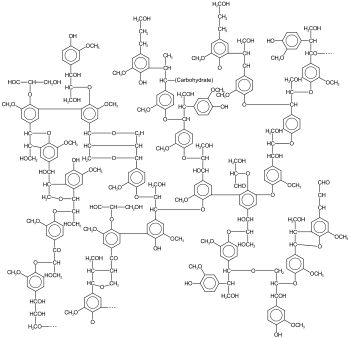

In chemistry, lignin is often called cross-linked phenolic polymer. It is a class of complex organic polymer which is very important in the formation of cell walls that serves to give stiffness so it is not easy to rot.

Bagasse is one of the sugar factory waste materials in which there is still lignin. Sugarcane bagasse can be regarded as by-product of sugar cane extraction process (nira). The bagasse used is a bagasse that has been extracted (grinding) for five times.

With lignin separation process, bagasse can add value because it can be alternative replacement fuel. One of the techniques and methods used to separate lignin from bagasse is by using NaOH reagents. Hydrolysis of lignocellulose to lignin can be done by using variation of NaOH. concentration and variation of powder size of bagasse. Then the result of lignin formed is characterized by FTIR spectroscopy method to know the typical functional group found in lignin structure and with standard commercial lignin FTIR spectrum so as to know optimal separation of lignin or not.

Second Generation Bioethanol Making Process Of Sugar Cane

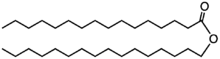

General definition of bioethanol is ethanol produced from plant raw materials such as corn, wheat, and sugar cane through the fermentation process. The second generation bioethanol which the author means here is ethanol from sugarcane. Making ethanol from sugarcane can be obtained from drops, bagasse and leaves. Drops, corn, cassava, wheat, and tubers can be directly converted to ethanol. While the dregs and trash is a lignocellulosic compound that can not be directly converted to ethanol. Lignocellulose must first be converted into cellulose, lignin and hemicellulose. Then the cellulose is broken down into glucose, then into ethanol. Cellulose needs to be degraded into silos that can be further converted to silitol. With this method, ethanol production will increase.

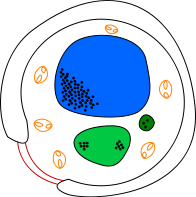

Usually in the ethanol fermentation process using yeast, because yeast contains microorganisms single-celled that can convert glucose into alcohol and CO2 gas.

Yeasts used in sugar processing are grouped into three types, among others:

1). Saccharomyces anamenesis

2). Schizosaccharomyces pombe

3). Saccharomyces cerevisiae. [Source]

Each of these yeasts has different alcohol-making abilities. Ethanol is a pure alcohol that has a chemical structure C2H5OH Ethanol. became one of the sources of organic fuel. The scientists also said: a source of renewable energy derived from the processing of organic materials requires a very small external energy.

In principle the reaction in the process of making ethanol with fermentation is by the following equation:

C6H12O6 = C2H5OH + CO2 [Source]

Based on the quotations and descriptions above, the second generation of sugar cane-based bioethanol can be done through two processes, namely hydrolysis and fermentation process by using yeast one-cell microorganisms to convert glucose into alcohol and CO2 gas. Thus, bioethanol (C2H5OH) is an ethanol compound produced from biomass engineering containing sugar, starch, or cellulose components through biological processes such as enzymatic and fermentation. Sugarcane waste is very potential to produce bioethanol because it comes from plants that have high carbohydrate levels. This bioethanol can be used as an alternate fuel alternative in sugar mills.

How to Turn Bagasse Into a Source of Electrical Energy?

There are 156 sugar factories In Cuba, it has generated 20 KWh of electricity for every ton of cane. The tool used to generate electricity from sugar cane is cogeneration (multilevel MFC). A 100 MW worth of US $ 1 billion with a calculation within 15 years is used in a sugar mill, and potential power can be added to the national network of 400 MW. While in Indonesia, the energy from bagasse has been used by many sugar factories as new steam producers and to generate the electricity needed to operate the sugar mills. Usually in 1 MT milled sugar cane produces 0,34 MT or 34 % of ground milled sugarcane which produces the dregs. Bagasse that used as fuel in the process of making sugar using cogeneration system that can be converted into electricity. The quantity of electricity generated by the cogeneration system with TCE technology is 150 MWh / day. While the use of BIG-GT technology can generate electricity of 750 MWh / day.

So the fuel produced from bagasse (second generation bioethanol) can be converted into electricity by a cogeneration system.

CONCLUSION

Based on the description above, the authors conclude several essence essence, that is as follows:

1). Sugarcane waste that is a sugar mill waste can produce second generation ethanol fuel.

2). Bioethanol of sugarcane-based waste can be produced through two ways, that are: hydrolysis and fermentation by using yeast containing microorganisms that can convert glucose into alcohol CO2 and gas.

3). The type of ethanol fuel produced from bagasse can be converted into electricity by cogeneration system.

4). Bioethanol can be used as alternative fuel for vehicles, industrial plants and even can be used for households.

Suggestion

This technology and method of making bioethanol needs to be developed for overcome the world energy crisis predicted to happen will be exhausted.

References

[1]. bioenerginusantara.com

[2]. wikipedia.org

[3]. slideus.org

[4]. www.konfrontasi.com

[5]. id.wikipedia.org

[6]. id.wikipedia.org/wiki

[7]. en.wikipedia.org

[8]. www.kompasiana.com

[9]. eckonopianto.blogspot.co.id

[9]. www.kompasiana.com

.jpeg)