Open-Circuit Vs. Closed-Circuit Cooling Tower

Both types serve the essential function of cooling water in various industrial applications, but they operate quite differently. Here’s a detailed look at their characteristics, advantages, and disadvantages.

Overview of Cooling Towers

Cooling towers are structures that remove heat from water by evaporating a portion of the water into the atmosphere. They are crucial in many industries, including power generation, chemical processing, and HVAC systems.

Open Circuit Cooling Towers

Open Circuit Cooling Towers operate by allowing water to flow through the tower and come into direct contact with air. Here’s how they work:

Mechanism

Water is pumped to the top of the tower and distributed over fill material, where it spreads out and comes into contact with the air. As the water flows down, some of it evaporates, removing heat and cooling the remaining water.

Advantages

Lower Initial Cost: Generally, open circuit systems have a lower initial investment since they do not require additional closed-loop equipment.

Simplicity: The design is straightforward, making maintenance easier.

Higher Cooling Efficiency: They can achieve lower water temperatures due to direct air contact.

Disadvantages

Water Loss: Evaporation leads to water loss, which may require additional water supply.

Contamination Risk: Since the water is exposed to the environment, it can become contaminated with debris, algae, and other pollutants.

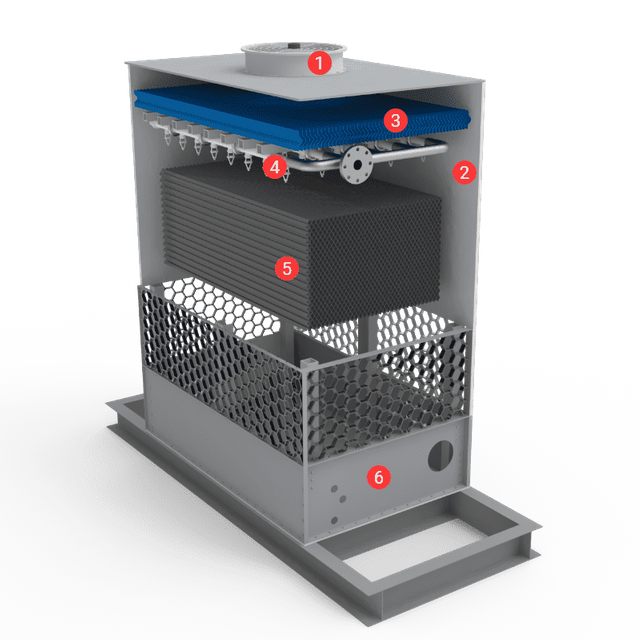

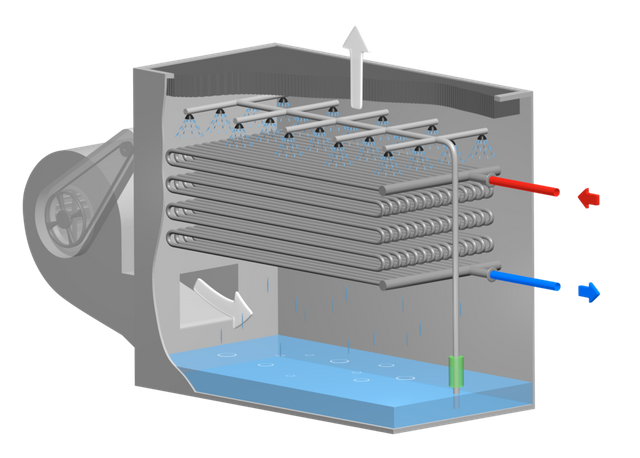

Closed Circuit Cooling Towers

Closed Circuit Cooling Towers utilize a different approach by incorporating a heat exchanger. Here’s how they function:

Mechanism

In a closed circuit system, water circulates through a heat exchanger coil inside the tower. The air cools the coil, and the heat is transferred to the air without direct contact between the water and air.

Advantages

Reduced Contamination: The water is not exposed to the atmosphere, minimizing the risk of contamination.

Lower Water Loss: Since evaporation occurs only from the surface of the coil, water loss is significantly reduced.

Better for Sensitive Applications: Ideal for processes that require high water purity.

Disadvantages

Higher Initial Cost: The need for additional equipment, like heat exchangers, increases the initial investment.

Lower Energy Efficiency: Closed circuit systems may have lower energy efficiency compared to open circuit systems due to the additional components involved.

The choice between an Open Circuit Cooling Tower and a Closed Circuit Cooling Tower largely depends on the specific needs of your application. If you prioritize lower initial costs and higher cooling efficiency, an open circuit system may be the way to go. However, if water purity and reduced contamination are critical, a closed circuit system would be more suitable.

Read more at: Everything About Open-Circuit and Closed-Circuit Cooling Towers | DamaTajhiz HVAC