Equivalent density and different forms of fluid circulation in an oil well

Hello friends and STEM content lovers.

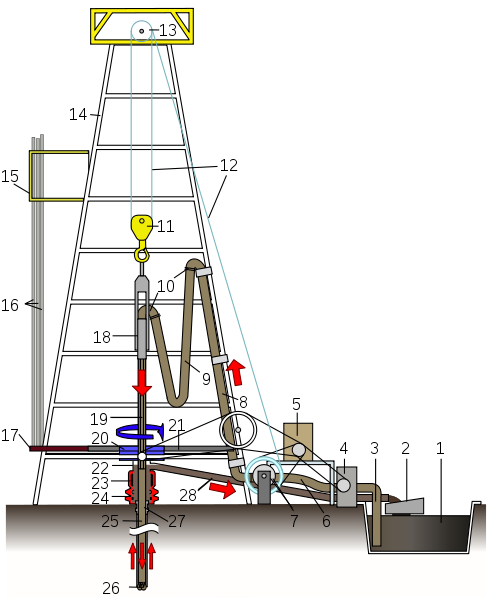

This time I want to share with you all a topic of well control within the field of petroleum engineering related to the different ways in which the equivalent circulating density manifests itself under the different ways in which a drilling fluid can circulate within the well, and that this in turn translates into different pressures downhole.

Equivalent density

In any type of operations in which a well may have a fluid inside it, the walls of the well are constantly under the action of a constant pressure.

However, the pressure at the bottom of the well will be influenced by four types of circumstances in which the drilling fluid can be inside the well and that will have a totally different bottomhole pressure in each of the cases.

Of all the pressures generated in the four circumstances, it is the hydrostatic pressure of the drilling fluid that exerts the highest pressure value, knowing of course that the hydrostatic pressure of the fluid is given when the well is static without fluid circulation.

Logically, it is not possible to have the drilling fluid static in the well all the time, since if our main operation is to drill, then there will be several occasions in which if it is static, we will circulate the drilling fluid by turning on the mud pumps, thus increasing the pressure at the bottom of the well.

It is important to note that the additional pressure added by the pump is only reflected on average between 200 to 500 PSI additional to the hydrostatic pressure, for example if we have the mud pumps off, and the drilling fluid is static in the well and the hydrostatic pressure is 5000 PSI, then with the pumps on it could generate a circulating pressure of 5220 PSI to 5500 PSI approximately, maybe it is not a considerable increase, however you should be comparing the circulating pressure and compare it constantly with the fracture pressure that can resist the formation to be fractured.

There are other pressures that are reflected in the bottom of the well when for example in drilling operations the well is closed and the well is circulated with a fluid of higher density to remove an influx of fluids such as gas and/or oil, in which the choke valve may be shocked, and with this the pressure in the bottom of the well is higher than the formation pressure, but in turn is less than the fracture pressure, and for this you have to be shocking the well, so there will be a constant variation of the pressure in the bottom of the well.

It is also important to clarify that the term shocking in oil jargon refers to having to open and close the opening and closing valve of the well to control the downhole pressure.

Circumstances in which the well may be and their influence on bottomhole pressure (BHP

[1]Static well.

A static well is a well that contains a drilling fluid throughout its circulation system, but is itself static, i.e. the drilling fluid is not moving, therefore the pressure at the bottom of the well is equal to the hydrostatic pressure in the annulus.

[2] Normal circulation.

Normal circulation refers to the circulation that the drilling fluid makes since it leaves the active tank driven by the mud pumps, exits through the jets of the bit downhole, and returns through the annular space and back to the active tanks and thus continue with the continuous and constant circulation.

The pressure at the bottom of the well will be the hydrostatic pressure plus the pressure generated by the mud pump to overcome friction losses, as I explained in my previous publications, we will call this pressure exerted by the mud pump as friction pressure loss.

[3] Rotary head circulation.

Circulation with rotary head is when we circulate the well with a rotary head, so the downhole pressure will be equal to the hydrostatic pressure of the drilling fluid plus the pressure generated by the mud pump (pressure losses due to friction in the annular space) and in addition to this we must add the pressure generated by the rotary head at the bottom of the well.

[4] Circulation of an upwelling outside the well.

If there is a slight impression that there is an invasion of fluids such as gas and oil into the well, then we turn off the mud pumps, if the well flows it is because the suspicions are true, so we proceed to close the well, When the well is closed, some pressures are trapped, such as casing pressure and drill pipe pressure, which is why it is necessary to release part of this pressure by shocking the choke valve, always looking for the pressure at the bottom to be higher than the inflow pressure (gas and/or oil) but less than the fracture pressure.

When a well is circulated to remove an invasive influx, the downhole pressure is equal to the hydrostatic pressure of the drilling fluid plus the pump pressure (friction pressure losses in the annulus) plus the pressure in the choke (casing).

Conclusion

It is very important to know the bottom hole pressure (BHP) in an oil well because it varies depending on whether the well is circulating drilling fluid or static, besides any operation of closing the well for further control also adds pressure at the bottom.

All this knowledge is transformed into an awareness at the time of operating both engineers and those responsible for crashing the valve on the choke line, where the pressures must be maintained at the bottom of the well above the formation pressure but below the fracture pressure.

Bibliography consulted and recommended.

- Well Control Manual. Well Control School (WCS). Harvey Louisiana. Year 2003.

Excellent, the experience in a publication!

Hi friend, I certainly take advantage of my experience as a petroleum engineer and having worked three years in oil well drilling to explain these engineering topics here on steemit. Greetings and thanks for commenting.